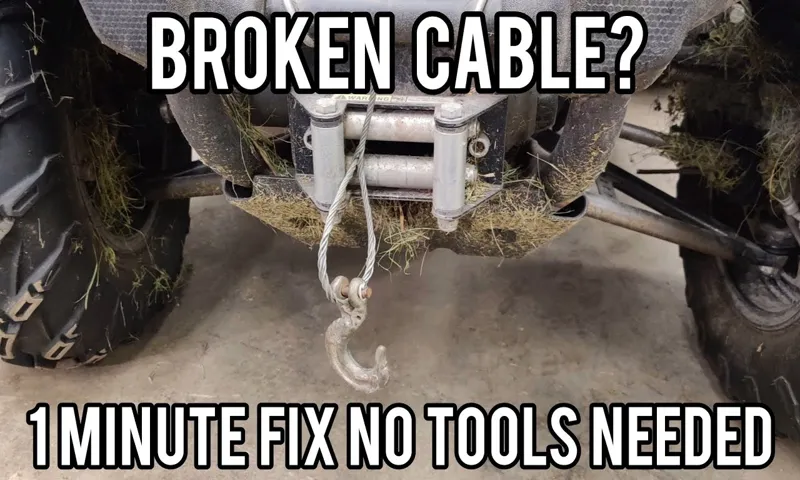

Are you an ATV enthusiast who loves off-roading adventures but is currently facing a broken winch cable? Don’t worry, because I am here to help you repair it and get back on the trails in no time! Your ATV winch cable plays a crucial role in helping you navigate through rugged terrain, pull out stuck vehicles, and tackle any obstacles in your path. However, over time, continuous use and exposure to harsh conditions can lead to wear and tear, eventually causing your winch cable to break. But fear not, because repairing a broken ATV winch cable is easier than you think.

In this blog post, I will guide you through step-by-step instructions on how to repair it yourself, saving you time and money. So grab your tools, put on your DIY hat, and let’s get started on fixing your broken ATV winch cable together!

Table of Contents

Introduction

Are you tired of dealing with a broken ATV winch cable? Don’t worry, because I’m going to show you how to repair it in just a few simple steps. Whether you’re out on a trail ride or stuck in a tricky situation, having a working winch is essential for any ATV enthusiast. The first step in repairing a broken winch cable is to assess the damage.

Take a close look at the cable and determine where the break has occurred. Is it a clean cut or is it frayed? The type of damage will determine the best course of action for repair. If the cable is cleanly cut, you can simply trim off the damaged section and reattach the cable to the drum.

Make sure to leave enough slack in the cable to allow for its movement when operating the winch. Use wire cutters to remove the damaged portion of the cable and then thread it through the fairlead and onto the drum. If the cable is frayed, you will need to replace it entirely.

Start by removing the old cable from the drum and fairlead. Then, measure the length of the old cable to ensure you purchase a replacement of the same size. Once you have the new cable, thread it through the fairlead and onto the drum, making sure to leave enough slack for movement.

To secure the cable to the drum, use a cable clamp or vice grip. Tighten it securely to prevent the cable from slipping or coming loose when in use. Double-check that the cable is properly threaded through the fairlead to ensure smooth operation.

It’s important to note that repairing a winch cable is a temporary solution. Over time, the cable may deteriorate or break again, especially if it has been subject to heavy use or damage. It’s always a good idea to have a spare winch cable on hand for emergencies.

Explanation of winch cable function

winch cable function

Importance of a strong winch cable

winch cable, strong winch cable

Assessing the Damage

If you own an ATV with a winch, you know how useful it can be for towing or pulling heavy objects. But what do you do when your winch cable breaks? Don’t worry, repairing a broken ATV winch cable is not as difficult as it may seem. First, you need to assess the damage and determine if the cable can be repaired or if it needs to be replaced entirely.

Look for any frayed or broken strands of wire, as these can indicate that the cable is beyond repair. If the damage is minor, such as a small cut or abrasion, you may be able to fix it by splicing the cable back together. However, if the cable is severely damaged or if it has snapped completely, it is best to replace it with a new one to ensure your safety.

Remember to always inspect your winch cable regularly for signs of wear and tear, and replace it if necessary to prevent any accidents or damage to your ATV.

Identifying the broken part

Identifying the broken part of a malfunctioning appliance is the first step in getting it repaired. When assessing the damage, it is important to carefully examine the appliance and look for any visible signs of wear and tear. This could include cracked or damaged parts, loose connections, or any other obvious issues.

In addition to visual inspection, it may also be necessary to test the different components of the appliance to determine which part is causing the problem. This can be done using a multimeter or other testing equipment. By carefully assessing the damage, it will be easier to accurately identify the broken part and take the necessary steps to fix it.

Checking for any other damage

When it comes to assessing the damage after an accident or incident, it’s important to check for any other damage that may not be immediately obvious. Sometimes, the impact of an event can cause hidden damage to various parts of your home or property. For example, a minor car accident may cause a crack in the foundation of your house or damage to the electrical wiring.

It’s essential to thoroughly inspect your property, both inside and out, to identify any other potential issues. This can save you from future headaches and costly repairs. Think of it like a puzzle – you want to make sure all the pieces are accounted for and put back together properly.

So take the time to carefully examine your property after an incident, and if needed, consult with a professional to ensure all the damage is identified and addressed. Whether it’s a cracked wall, a leaking pipe, or damaged wiring, it’s better to know about it sooner rather than later. After all, prevention is always better than cure.

Gathering the Necessary Materials

If you own an ATV, a winch is an essential tool to have. It allows you to pull yourself out of sticky situations and gives you the confidence to tackle any terrain. However, over time, the winch cable can break or become damaged, rendering it useless.

But don’t worry, repairing a broken ATV winch cable is easier than you might think. To start, you’ll need to gather the necessary materials. First and foremost, you’ll need a replacement winch cable.

Make sure to choose a cable that is the appropriate length and has the same weight capacity as your original cable. Additionally, you’ll need a pair of pliers, a socket wrench, and a winch cable stopper. The pliers will come in handy for removing the old cable and installing the new one, while the socket wrench will be used to loosen and tighten the necessary bolts.

The winch cable stopper is a small but important piece that prevents the winch cable from unraveling. Once you have all the materials ready, you can begin the repair process. Start by disconnecting the power supply to the winch and removing any accessories or covers that may be in the way.

Using the pliers, carefully remove the broken winch cable from the attachment point on the winch drum. Take note of how the cable is routed through the fairlead and make sure to replicate this when installing the new cable. Next, attach the new winch cable to the winch drum, ensuring that it is securely fastened.

Use the pliers to tighten any bolts or screws that may be holding the cable in place. Once the cable is attached to the winch drum, thread it through the fairlead, taking care not to twist or kink the cable. Finally, attach the winch cable stopper to the end of the cable, making sure it is securely in place.

List of tools and supplies needed

When it comes to building, fixing, or creating something, gathering the necessary tools and supplies is a crucial first step. Having the right equipment on hand can make your project go smoothly and efficiently. So, what tools and supplies do you need? The answer will depend on the specific task at hand, but there are a few basic items that every DIY enthusiast should have in their arsenal.

A good set of screwdrivers, both flathead and Phillips, is essential for any project that involves screws. A tape measure is another must-have tool, as precise measurements are crucial for a successful outcome. Other useful tools to have include a level, a utility knife, pliers, and a hammer.

Along with the tools, it’s important to have a well-stocked supply of materials. This could include things like nails, screws, adhesive, sandpaper, paint brushes, and safety equipment such as gloves and goggles. By having these tools and supplies on hand, you’ll be ready to tackle any DIY project that comes your way.

So, gather your tools, stock up on supplies, and let your creativity shine!

Where to purchase the materials

materials, purchase, gathering, necessary materials

Removing the Old Winch Cable

So, you’ve found yourself with a broken ATV winch cable. Don’t worry, it happens to the best of us. The first step in repairing your broken cable is to remove the old one.

Start by locating the end of the cable that is connected to the winch drum. This is usually found near the top of the winch. Next, find the bolt or pin that is holding the cable in place.

Depending on the make and model of your winch, this may require the use of a wrench or pliers. Once you have removed the bolt or pin, carefully unwind the old cable from the winch drum. Be sure to keep a firm grip on the cable as you unwind it to prevent it from tangling or getting caught on any other parts of the winch.

Once the cable is fully unwound, you can remove it from the winch drum and set it aside. Congratulations, you’ve successfully removed the old winch cable! Now you can move on to the next step in repairing your ATV winch.

Step-by-step guide to removing the broken cable

If you’re facing the frustrating and potentially dangerous situation of a broken winch cable, don’t worry! With a step-by-step guide, removing the old cable can be an easy and stress-free process. The first step is to ensure that your winch is turned off and the vehicle is in park or neutral to prevent any unexpected movement. Next, locate the end of the broken cable and disconnect it from the drum.

Depending on the type of winch you have, this may involve removing bolts or pins. Once the cable is disconnected, carefully unspool it from the drum, making sure to avoid any kinks or tangles. After the cable is fully removed, inspect the drum for any damage or signs of wear.

If necessary, clean and lubricate the drum before installing the new cable. With these simple steps, you’ll be well on your way to replacing your broken winch cable and getting back to enjoying your off-road adventures.

Safety precautions to take

Safety precautions

Installing the New Winch Cable

If you find yourself in a sticky situation with a broken ATV winch cable, fear not! Installing a new cable is actually a fairly straightforward process. First, you’ll want to disconnect the old cable from the winch drum and remove any remaining pieces from the fairlead. Then, it’s time to attach the new cable.

Begin by threading it through the fairlead and over the winch drum, being careful to prevent any twists or tangles. Once it’s in place, secure the cable by inserting the end through the looped eyelet and then attach the hook to the other end. Finally, give the cable a test run to ensure it’s operating smoothly and securely.

With this easy-to-follow process, you’ll be back in action with a functioning winch cable in no time.

Step-by-step guide to installing the new cable

Installing the New Winch Cable: A Step-by-Step Guide So, you’ve purchased a new winch cable and you’re ready to install it. Congratulations! With a little bit of know-how and some patience, you’ll have your winch up and running in no time. Follow these steps to ensure a smooth installation process.

Step 1: Gather your tools Before you begin, make sure you have all the necessary tools at hand. You’ll need a wrench, pliers, and a socket set. It’s always a good idea to have a pair of gloves and safety goggles as well.

Step 2: Disconnect the old cable Start by disconnecting the old winch cable from the winch drum. Use your wrench to loosen the bolts and remove the old cable. Take note of how the old cable was threaded through the drum.

This will help you when installing the new one. Step 3: Attach the new cable to the winch drum Next, take your new winch cable and thread it through the winch drum in the same way the old cable was threaded. Make sure to follow the manufacturer’s instructions for the correct method of attachment.

Use your pliers to secure any clips or clamps. Step 4: Extend the cable Once the cable is securely attached to the winch drum, you’ll need to extend it fully. This can be done by slowly operating the winch until the cable is fully extended.

Be careful not to let the cable slip or tangle during this step. Step 5: Attach the hook With the cable extended, attach the hook to the end of the cable. Again, refer to the manufacturer’s instructions for the correct method of attachment.

Proper technique for securing the cable

Securing the cable properly when installing a new winch is crucial for its performance and safety. To ensure a secure and stable connection, follow these steps: Start by feeding the cable through the drum of the winch.

Make sure it goes over the top of the drum before pulling it out through the fairlead. Once the cable is threaded through, pull out enough slack to make a loop around the base of the winch drum.

This loop will serve as an anchor point for securing the cable. Take the loose end of the cable and thread it back through the loop you just created.

Pull it tight to form a secure and tight connection. To add extra security, use a cable clamp to hold the loose end of the cable in place.

Place the clamp over the cable and tighten the screws to ensure a firm grip. Finally, give the cable a few tugs to test its strength and stability.

It should feel solid and secure, with no signs of slipping or loosening. By following these steps, you can rest assured that your winch cable is properly installed and ready to handle any heavy-duty towing or pulling tasks. Remember to regularly inspect and maintain your winch cable to ensure its long-term performance and safety.

Testing the Repair

If you enjoy off-roading adventures, chances are that you have an ATV winch installed on your vehicle. However, just like any other piece of equipment, the winch cable can get damaged over time. If you find yourself in a situation where your ATV winch cable has broken, don’t worry – repairing it is easier than you might think.

Firstly, you will need to remove the broken cable from the winch drum, which can usually be done by loosening a few bolts or screws. Next, you will need to attach a new winch cable to the drum and secure it tightly. Make sure to wind the new cable evenly and avoid any tangles or overlaps.

Finally, test the repair by operating the winch and pulling a heavy load. If the cable holds up and operates smoothly, congratulations! You have successfully repaired your ATV winch cable. Remember, safety should always be your priority, so don’t hesitate to consult a professional if you’re unsure about any step of the process.

Ensuring the winch cable is functioning correctly

winch cable, functioning, testing the repair After repairing the winch cable, it’s important to ensure that it is functioning correctly before putting it to use. Testing the repair will give you peace of mind and help prevent any accidents or further damage. Start by checking the cable for any visible signs of wear or damage.

Look for frayed strands or kinks, as these can weaken the cable and make it unsafe to use. Next, slowly extend the cable and listen for any unusual sounds, such as grinding or squeaking. These could be indications of internal damage that may need to be fixed.

To test the strength of the cable, attach a heavy load and slowly lift it. Pay attention to any sudden drops or shifts in the load, as this could indicate a problem with the cable’s strength or integrity. Additionally, test the winch’s ability to smoothly retract the cable.

Make sure there are no jerky or uneven movements as the cable is being reeled in. By thoroughly testing the repair, you can ensure that your winch cable is functioning correctly and ready for use in any situation.

Tips for proper maintenance

Testing the Repair: Tips for Proper Maintenance After completing a repair on a piece of equipment or machinery, it is essential to thoroughly test the repair to ensure it has been properly fixed and is functioning correctly. Testing the repair is an important step in proper maintenance, as it allows you to identify any lingering issues or potential problems before they cause further damage or breakdowns. To effectively test the repair, start by conducting a visual inspection, checking for any loose or damaged parts, leaks, or signs of wear and tear.

Next, perform a functional test to assess the operation of the equipment. This can involve running the machinery or using the equipment as it would be used in its regular operation. During the functional test, pay attention to any unusual noises, vibrations, or changes in performance.

These can be indicators of underlying issues that may require further attention. If you notice any problems, it is important to address them promptly to prevent further damage or breakdowns. In addition to a functional test, it may also be necessary to perform specialized tests for certain types of equipment.

For example, electrical equipment may require testing for voltage, current, or insulation resistance. Similarly, mechanical equipment may need to be tested for alignment, balance, or pressure. By thoroughly testing the repair, you can ensure the equipment or machinery is in proper working order and ready for use.

This not only increases the lifespan of the equipment but also improves safety and efficiency in operations. Remember, regular maintenance and testing are key to preventing costly breakdowns and ensuring the longevity of your equipment.

Conclusion

And there you have it, folks—the foolproof guide to repairing a broken ATV winch cable. Just remember, with a little bit of patience, some handy tools, and a sprinkle of ingenuity, you’ll be back on track in no time. So the next time your winch cable decides to snap on you, don’t fret.

Simply follow these steps and show that cable who’s boss. Trust me, your ATV winch will thank you for it. And who knows, you might even earn the title of the MacGyver of Off-Road Recovery.

Now, go out there and conquer those treacherous terrains, because with a repaired winch cable, you’re unstoppable!”

Summary of the repair process

repair process, testing the repair

Importance of regular maintenance

As a car owner, regular maintenance is crucial to ensure the longevity and optimal performance of your vehicle. One essential aspect of this maintenance is testing the repair work done on your car. Whether it’s a minor fix or a major repair, it’s important to test the results to ensure that everything is functioning as it should.

Testing the repair allows you to identify any lingering issues or potential problems that may have been missed during the repair process. This step is particularly important when it comes to safety-related repairs or any repairs that involve critical components of your car’s systems. By testing the repair, you can have peace of mind knowing that your car is safe and in good working order.

Additionally, testing the repair can help you catch any small issues before they develop into larger, more expensive problems down the road. It’s always better to address any potential issues early on rather than wait until they become more serious and costly to fix. So, the next time you have your car repaired, make sure to test the repair to ensure that your vehicle is in top condition.

FAQs

How do I repair a broken ATV winch cable?

To repair a broken ATV winch cable, you will need to first cut off the damaged section of the cable. Then, attach a cable repair kit or use a cable clamp to join the two ends securely. Make sure to follow the instructions provided with the repair kit for best results.

Can I repair a frayed ATV winch cable myself?

Yes, you can repair a frayed ATV winch cable yourself. Start by trimming the frayed ends to prevent further damage. Then, use a cable repair kit or cable clamp to secure the ends together. Make sure to follow the instructions provided with the repair kit for proper installation.

What tools do I need to repair a broken ATV winch cable?

To repair a broken ATV winch cable, you will need a cable cutter or sharp knife to cut off the damaged section. Additionally, you will need a cable repair kit or cable clamp to join the two ends together. Extra tools may be required depending on the specific repair kit being used, so refer to the instructions provided.

Where can I find a cable repair kit for my ATV winch cable?

Cable repair kits for ATV winch cables can be found at most hardware stores, automotive stores, or online retailers. It is important to choose a kit that is compatible with the diameter and strength of your broken cable for a proper repair.

How long does it take to repair a broken ATV winch cable?

The time it takes to repair a broken ATV winch cable will depend on your experience level and the specific repair kit being used. On average, the process can take anywhere from 30 minutes to an hour.

Can I use a regular steel cable to repair my ATV winch cable?

It is not recommended to use a regular steel cable to repair an ATV winch cable. ATV winch cables are specially designed for their strength, flexibility, and durability. Using a regular steel cable may compromise the performance and safety of your ATV winch.

Is it better to replace or repair a broken ATV winch cable?

If the damage to the ATV winch cable is extensive or if it has been repaired multiple times before, it may be better to replace the cable altogether. However, if the damage is minor and the cable is in overall good condition, a repair can usually be performed effectively.