Hey there! Welcome to our blog on the fascinating topic of “Introduction”. Whether you’re a student writing an essay or a professional giving a presentation, introductions play a crucial role in capturing the attention of your audience. Just like the opening scene of a movie, a well-crafted introduction sets the tone, grabs the audience’s interest, and prepares them for what’s to come.

Imagine you’re at a party, and someone you’ve never met before approaches you. How would you like them to start the conversation? Probably not with a long-winded monologue about themselves, right? Instead, you’d prefer a catchy icebreaker that piques your curiosity and makes you want to engage in further conversation. The same principle applies to introductions in any form of communication.

Think of an introduction as a trailer for what’s about to unfold. It should provide a sneak peek into the main ideas, just enough to hook the audience and make them eager to delve deeper into the topic. An effective introduction should be concise, captivating, and above all, set clear expectations.

You want your audience to know what they’re in for and why it matters to them. To achieve this, you can incorporate rhetorical questions, analogies, or metaphors that spark the reader’s imagination. For instance, when discussing the importance of introductions, you might compare them to the first bite of a delicious meal or the initial chord of a captivating melody.

These literary devices not only engage the reader but also make the content more relatable and memorable. In this blog, we’ll explore the art of introduction, unravel its secrets, and equip you with practical tips to become a master at captivatin. So sit back, relax, and get ready to embark on a journey to unlock the power of introductions.

Whether you’re writing an essay, giving a speech, or simply engaging in a conversation, by the end of this blog, you’ll have all the tools you need to create attention-grabbing introductions that will leave a lasting impact. Let’s get started!

Table of Contents

What is an ATV Winch Connector?

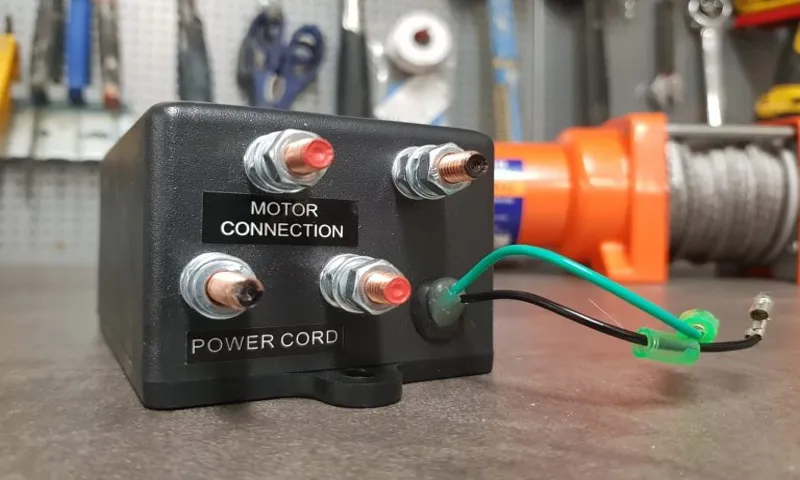

ATV winch connectors are an essential part of any ATV winch system. They are the link between the winch and the power source, allowing the winch to draw power from the ATV’s battery or another power source. These connectors are typically made of heavy-duty materials like high-quality copper to ensure a stable and reliable connection.

When using an ATV winch, it is important to regularly test the connectors to ensure they are functioning properly. One way to test the connectors is to use a multimeter to check for continuity. This involves disconnecting the connectors from the winch and measuring the resistance between the positive and negative terminals.

A low resistance reading indicates good connectivity, while a high reading suggests a faulty or damaged connector. Another way to test the connectors is to perform a load test. This involves connecting the winch to a load and checking if the connectors can handle the weight without getting overheated or damaged.

It is important to follow the manufacturer’s instructions and recommendations for load testing to ensure safety and prevent any potential damage to the connectors or the winch system. Regularly testing and maintaining the ATV winch connectors is crucial for optimal winching performance and safety. By ensuring that the connectors are in good working condition, you can have peace of mind knowing that your winch system will work reliably when you need it most.

Why Test ATV Winch Connectors?

If you own an ATV, you know how important it is to have a reliable winch. But have you ever thought about the connectors that make it all work? Testing your ATV winch connectors is crucial to ensuring their reliability and performance. These connectors play a vital role in connecting the winch to the power source, and any issues with them can result in a loss of power, slow operation, or even complete failure.

So, how can you test your ATV winch connectors? One way is to visually inspect them for any signs of damage or wear. Look for loose connections, corrosion, or frayed wires. Another method is to use a multimeter to check for continuity and proper electrical flow.

By testing your ATV winch connectors, you can identify any potential issues before they become bigger problems, giving you peace of mind during your ATV adventures. Don’t wait until you’re stranded in a sticky situation – make sure your ATV winch connectors are in good working order.

Are you someone who loves off-roading adventures on your ATV? If so, you probably rely on your trusty winch to help you out of sticky situations. However, just like any other piece of equipment, the winch connectors on your ATV winch can wear out over time. That’s why it’s crucial to regularly test your ATV winch connectors to ensure they are in proper working condition.

In this blog post, we will walk you through some simple steps on how to test your ATV winch connectors so that you can keep enjoying your off-roading adventures with peace of mind.

Step 1: Visual Inspection

When it comes to testing ATV winch connectors, the first step is to visually inspect them. This is important because it allows you to identify any obvious signs of damage or wear and tear. Start by examining the connectors for any visible cracks, breaks, or loose connections.

Check the insulation around the wires for any fraying or damage. Also, make sure that the connectors are clean and free from any dirt or corrosion. If you notice any issues during your visual inspection, it may be necessary to replace the connectors before testing the winch.

Remember, taking the time to thoroughly inspect the connectors can help ensure their proper functioning and prevent any potential problems down the line.

Inspect the Connector Housing

While inspecting the connector housing, the first step is to visually examine it for any signs of damage or wear. Take a close look at the housing for any cracks, dents, or discoloration. These could be indicators of potential issues with the connector.

It’s important to thoroughly inspect the housing as any damage can affect the overall performance and longevity of the connector. Just like a car with a cracked windshield, a damaged connector housing may not be able to handle the demands of its job properly. By identifying any visual problems, you can address them early on and prevent any further damage or loss of function.

Check for Loose or Damaged Wires

During the lifetime of any electrical system, loose or damaged wires can occur due to various reasons such as wear and tear, rodent damage, or improper installation. It is important to regularly check for loose or damaged wires to ensure the safety and functionality of your electrical system. In this blog post, we will discuss the first step of this process, which is visual inspection.

Visual inspection involves carefully examining all the visible wires in your electrical system. Start by turning off the power to the area you will be inspecting to avoid any accidents. Use a flashlight to have a clear view of the wires, especially in dark areas such as crawlspaces or basements.

Look for any obvious signs of loose or damaged wires, such as frayed insulation, exposed wires, or loose connections. Pay close attention to areas where wires may have been bent or twisted, as these are potential weak points. While conducting the visual inspection, ask yourself some questions.

Are there any wires that look out of place or appear to be hanging loosely? Are there any signs of rodent activity, such as chewed wires? Are there any wires that are touching each other or any other objects that could cause a short circuit? By asking these questions, you can identify potential issues and address them before they become a major problem. Sometimes, loose or damaged wires can be difficult to spot, especially if they are hidden behind walls or in hard-to-reach areas. In such cases, it may be necessary to consult a professional electrician who has the tools and expertise to conduct a more thorough inspection.

They can use specialized equipment, such as thermal imaging cameras, to detect any abnormal heat patterns that may indicate loose or damaged wires. In conclusion, visual inspection is the first step in checking for loose or damaged wires in your electrical system. By carefully examining all visible wires and looking for any signs of wear and tear, you can identify potential issues and address them before they cause any safety hazards or damage to your electrical system.

Remember to always turn off the power before conducting any inspections and consult a professional electrician if needed.

Look for Corrosion

visual inspection

Step 2: Resistance Testing

If you’re looking to ensure the reliability and durability of your ATV winch connectors, resistance testing is a crucial step. This process will help you identify any issues with the connectors, such as loose or damaged connections, which could impact the performance of your winch. To conduct a resistance test, you will need a multimeter.

First, set the multimeter to measure resistance (ohms) and connect the black lead to the negative terminal of the winch battery and the red lead to the positive terminal. Then, touch the multimeter probes to the corresponding terminals of the winch connectors. A good connector should have a low resistance reading, indicating a solid connection.

If the resistance is high or the reading fluctuates, it may indicate a problem with the connector that needs to be addressed. By regularly testing the resistance of your ATV winch connectors, you can ensure optimal performance and avoid any potential issues while out on the trails.

Using a Multimeter

multimeter, resistance testing, electrical circuits, ohms, troubleshooting, continuity

Testing the Power and Ground

power and ground, resistance testing, automotive electrical systems, troubleshooting, continuity, multimeter In order to troubleshoot automotive electrical systems effectively, it is crucial to test the power and ground connections. This is where resistance testing comes into play. Resistance testing is a method used to measure the resistance or continuity of a circuit using a multimeter.

By testing the resistance, we can determine if there are any breaks or excessive resistance in the power and ground connections. When performing a resistance test, the first step is to set your multimeter to the resistance or continuity setting. Next, you will need to connect the test leads to the power and ground connections you want to test.

It is important to ensure that the connections are secure to get accurate readings. Once the test leads are connected, you can then activate the multimeter to start the resistance test. During the test, the multimeter will send a small amount of current through the circuit and measure the resistance.

If the circuit has good continuity, the resistance reading will be close to zero. However, if there is a break or excessive resistance in the circuit, the reading will be significantly higher. This indicates a problem with the power or ground connection that needs to be addressed.

Resistance testing is an essential tool in troubleshooting automotive electrical systems. By testing the power and ground connections, we can identify any issues and take the necessary steps to fix them. So, whether you’re dealing with a faulty light or a malfunctioning stereo, don’t forget to perform a resistance test to ensure the power and ground connections are in good working order.

Step 3: Load Testing

So, you’ve bought yourself a shiny new ATV winch and you’re ready to put it to the test. But before you hit the trails, it’s important to ensure that your winch connectors are up to the task. Load testing is an essential step in this process.

Load testing involves applying a controlled amount of weight or force to the winch connectors to verify their strength and durability. This can be done using weights or other heavy objects, and should be performed in a controlled environment to ensure safety. By performing load testing on your ATV winch connectors, you can have peace of mind knowing that they will hold up under pressure when you need them most.

So don’t skip this important step – take the time to test your winch connectors and ensure they’re ready to handle whatever you throw at them.

Attaching a Load to the Winch

load testing, attach a load, winch In Step 3 of attaching a load to the winch, the next crucial step is load testing. Load testing is an essential part of ensuring that the winch is capable of handling the weight and strain that will be placed on it. This step involves adding a known weight to the winch and testing its performance under load.

The purpose of load testing is to assess the winch’s capacity and to identify any potential issues or weaknesses before using it for heavy lifting or pulling tasks. By conducting load testing, you can have confidence that the winch is capable of safely handling the intended load. It is important to follow the manufacturer’s guidelines and recommendations for load testing to ensure the accuracy and reliability of the results.

So, before putting your winch to work, make sure to include load testing as an important step in the process to ensure safe and successful operation.

Testing the Functionality

load testing, functionality, software, performance, simulate, virtual users. In the third step of testing the functionality of your software, load testing becomes a crucial aspect. Load testing is the process of simulating a high volume of users accessing your software simultaneously to gauge how it handles the increased workload.

By doing so, you can determine if your software can handle the expected number of users without any performance issues. Load testing allows you to analyze the performance of your software under stress and identify any weaknesses or bottlenecks that could hinder its functionality. It is an essential step in ensuring that your software can handle the expected number of users without crashing or slowing down.

To perform load testing, you need to simulate a virtual user load that is close to your expected user traffic. This can be achieved by using various tools and techniques to generate virtual users and simulate their interactions with the software. By conducting load testing, you can determine the maximum number of users your software can handle before experiencing performance issues.

It helps you identify any scalability issues and optimize your software to improve its performance under high loads. Load testing also helps you ensure that your software is reliable and stable, even when faced with heavy traffic. It allows you to identify any potential bottlenecks early on and address them before they become a problem for actual users.

In conclusion, load testing is an essential step in testing the functionality of your software. It helps you identify and address any performance issues, ensuring that your software can handle the expected number of users without any problems. By simulating a high volume of users, you can analyze the performance of your software under stress and optimize it to improve its overall functionality.

Step 4: Repeat Testing

After completing the initial testing of the ATV winch connectors, it is important to repeat the testing process to ensure accuracy and reliability. This step is crucial because it allows you to double-check the results and identify any inconsistencies or errors that may have occurred during the first round of testing. By repeating the testing process, you can be confident that the ATV winch connectors are functioning properly and will be able to handle the load required for your specific needs.

Additionally, repeating the testing process allows for any necessary adjustments or repairs to be made before the ATV winch connectors are put into regular use. Overall, repeating the testing process is an essential step in ensuring the effectiveness and safety of your ATV winch connectors.

Periodic Testing for Longevity

Once you have completed an initial round of testing on your website or application, it may be tempting to think that your job is done. However, in order to ensure the longevity and effectiveness of your product, it is important to incorporate periodic testing into your development process. Periodic testing involves conducting regular checks and assessments to identify any issues or bugs that may have been missed during the initial testing phase.

This step is essential because it allows you to catch any potential problems early on, before they have a chance to negatively impact your users’ experience. Just like how a car needs regular maintenance to stay in good working order, your website or application needs regular testing to ensure that it remains functional and user-friendly. So, don’t forget to make periodic testing a regular part of your development cycle.

Your users will thank you for it!

Signs to Watch Out For

If you’re concerned about a potential medical condition, it’s important to pay attention to the signs your body may be giving you. One of the key steps in diagnosing a condition is to repeat testing. This is important because sometimes test results can vary, and repeating tests can provide a more accurate picture of your health.

By repeating tests, healthcare professionals can look for any changes or patterns that may help with diagnosis. Additionally, some conditions may not be immediately apparent and may require multiple tests over time to confirm a diagnosis. So, if you’re experiencing symptoms or have received abnormal test results, don’t hesitate to talk to your doctor about repeating the tests.

It could provide valuable information and help you on your journey to better health.

Are you looking for a satisfying conclusion to your blog post? Wrapping up your content can be a challenging task, as you want to leave your readers with a sense of finality and closure. However, this does not mean you have to resort to cliches or generic statements. In fact, a well-crafted conclusion can leave a lasting impression on your audience, prompting them to take action or continue exploring your website.

In this blog post, we will explore effective strategies for writing conclusions that are engaging, impactful, and memorable. So, let’s dive in and discover how to end your blog posts with a bang!

Importance of Testing ATV Winch Connectors

When it comes to using an ATV winch, it’s crucial to ensure that the connectors are functioning properly. Testing ATV winch connectors is an important step to take before heading out on any off-road adventure. But how do you go about testing them? One method is to visually inspect the connectors for any signs of damage, such as corrosion or frayed wires.

You can also use a multimeter to check the continuity of the connectors, making sure that the electrical flow is uninterrupted. Another way to test the connectors is to perform a pull test, where you connect the winch to a sturdy object and engage the winch to see if the connectors hold up under pressure. By taking the time to test your ATV winch connectors, you can have peace of mind knowing that they will work when you need them the most.

Ensuring Reliable Winch Performance

When it comes to testing ATV winch connectors, it’s important to ensure reliable performance. One way to do this is by conducting a thorough inspection of the connectors before and after each use. Check for any signs of damage or wear, such as frayed wires or loose connections.

It’s also a good idea to test the connectors under load to see how they hold up. This can be done by attaching the winch to a heavy object and putting it through its paces to ensure it operates smoothly and efficiently. Additionally, it’s important to regularly clean and maintain the connectors to prevent corrosion and ensure optimal performance.

By following these steps, you can ensure that your ATV winch connectors will function reliably when you need them most.

Conclusion

In conclusion, testing your ATV winch connectors is not only a crucial step in ensuring your winch is in peak condition, but it can also be an entertaining and enlightening experience. Just grab a few items you probably already have lying around the garage, follow the steps outlined above, and before you know it, you’ll be delighting your friends with tales of your winch connector testing prowess. So, next time you find yourself in need of some ATV winch connector testing, remember to approach the task with an open mind, a sense of adventure, and maybe even a little bit of whimsy.

Who knows, you might just uncover a hidden talent for unraveling the mysteries of winch connectors and become the envy of your fellow off-roaders. Happy testing, and may your winch connectors always be secure and reliable!”

FAQs

How do I test ATV winch connectors?

To test ATV winch connectors, you can use a multimeter to check for continuity in the wiring. First, disconnect any power source and remove the connectors. Set your multimeter to the continuity or resistance mode and touch the probes to each end of the connector. If you get a reading of zero resistance or hear a beep, it means the connector is functioning properly. If there is no continuity, it indicates a faulty connection that needs to be repaired or replaced.

What are the common signs of a faulty ATV winch connector?

Signs of a faulty ATV winch connector can include intermittent power, difficulty in engaging or disengaging the winch, or no response from the winch when the controls are activated. If you notice any of these issues, it is recommended to check the connectors for any signs of damage, corrosion, or loose connections.

Can I replace ATV winch connectors myself?

Yes, you can replace ATV winch connectors yourself if you have some basic knowledge of electrical connections. Start by disconnecting the power source and remove any coverings or fasteners that secure the connectors. Take note of the existing wiring connections and carefully remove the old connectors. Then, install the new connectors by matching the wire colors and reconnecting them securely. Finally, test the winch to ensure proper functionality.

Are ATV winch connectors universal or specific to a particular brand?

ATV winch connectors can vary between different brands and models. While there may be common connector types used in the industry, it is recommended to consult the winch manufacturer’s instructions or customer support to determine the specific connectors required for your ATV winch.

How can I prevent ATV winch connectors from getting damaged?

To prevent ATV winch connectors from getting damaged, it is important to keep them clean and dry. Avoid exposing the connectors to excessive moisture, dirt, or debris. Regularly inspect the connectors for any signs of damage or corrosion and replace them if necessary. Additionally, proper handling and storage of the winch and its accessories can help prevent accidental damage to the connectors.

Can I use aftermarket connectors for my ATV winch?

It is generally recommended to use connectors specifically designed for your ATV winch. Aftermarket connectors may not have the same quality or compatibility, which could result in improper connections or potential electrical issues. It is best to consult the winch manufacturer or a professional for guidance on suitable connector options if needed.

How often should I inspect my ATV winch connectors?

It is good practice to inspect your ATV winch connectors regularly, especially before any off-road trips or heavy use. Ideally, you should inspect the connectors every few months or after any notable impact or exposure to harsh conditions. By conducting routine inspections, you can identify any potential issues early on and address them before they cause further damage or failure.