When it comes to off-roading adventures, an ATV winch solenoid is an essential component that every ATV enthusiast should be familiar with. But what exactly is it, and why is it so important? Think of an ATV winch solenoid as the powerhouse behind your ATV’s winching system. It is a small device that acts as a switch, controlling the flow of electricity from your ATV’s battery to your winch.

Without a functioning ATV winch solenoid, your winch would be rendered useless. So, why is it so important? Well, imagine you’re out on a trail, and your ATV gets stuck in a precarious situation. Maybe you’ve ventured too far into a muddy swamp or found yourself in a deep ravine.

In moments like these, your ATV winch solenoid becomes your lifeline. It enables you to engage your winch, allowing you to pull yourself out of the predicament and get back on track. But why do you need a solenoid specifically? Couldn’t you just connect the winch directly to your battery? While it may technically be possible, it is highly discouraged.

Without a solenoid, you risk overloading your winch and draining your battery, resulting in potential damage to both your ATV and yourself. The solenoid acts as a safety measure, regulating the electricity flow and protecting your ATV’s electrical system. So, next time you hit the trails, make sure to give your trusty ATV winch solenoid a little appreciation.

It’s the unsung hero behind your winch, ensuring that you can tackle any obstacle that comes your way. Stay tuned as we dive deeper into the intricacies of ATV winch solenoids and explore their various features and benefits.

Table of Contents

- 1 Section One: Understanding the basics of an ATV winch solenoid

- 2 Section Two: Signs that your ATV winch solenoid may need testing

- 3 Section Three: Tools needed for testing an ATV winch solenoid

- 4 Section Four: Step-by-step guide on how to test an ATV winch solenoid

- 5 Section Five: Understanding the test results

- 6 Conclusion: Importance of regular testing and maintenance

- 7 Appendix: Additional resources and troubleshooting tips

- 8 FAQs

Section One: Understanding the basics of an ATV winch solenoid

If you own an ATV and have a winch installed, you know how important it is to have a properly functioning ATV winch solenoid. The solenoid is responsible for engaging and disengaging the winch motor, allowing you to control the pulling and releasing of the winch cable. But what happens when your winch isn’t working as it should? One of the first steps in troubleshooting the issue is to test the ATV winch solenoid.

Fortunately, this is a relatively simple task that you can do yourself. To test your ATV winch solenoid, you will need a few basic tools, such as a multimeter. Start by disconnecting the winch cables from the battery.

Next, use the multimeter to check the continuity of the solenoid. If there is no continuity, it means the solenoid is faulty and needs to be replaced. However, if there is continuity, you will need to test the power supply to the solenoid.

This can be done by connecting the solenoid to a battery and using the multimeter to check for voltage. If there is no voltage, it indicates a problem with the power supply, and further troubleshooting will be required. By following these simple steps, you can quickly determine if your ATV winch solenoid is the culprit behind your winch issues and take the appropriate action to fix it.

Subsection 1.1: What is a solenoid?

ATV winch solenoids are an essential component of an ATV winch system. But what exactly is a solenoid? Well, think of it as the power switch that controls the movement of your ATV winch. It works by converting electrical energy into mechanical energy, allowing you to control the pulling and releasing of the winch cable.

The solenoid essentially acts as a gatekeeper, regulating the flow of electrical current to the winch motor. When you engage the winch, the solenoid sends power to the motor, causing it to turn and pull the cable. And when you release the winch, the solenoid cuts off the power, allowing the cable to be released.

So, in a way, the solenoid is like the conductor of an orchestra, directing the flow of electricity and coordinating the movements of the winch. Without a functioning solenoid, your ATV winch would be rendered useless.

Subsection 1.2: How does an ATV winch solenoid work?

ATV winch solenoids are essential components in the operation of an ATV winch. But how exactly do these solenoids work? Well, think of the solenoid as a switch that controls the flow of electrical current to the winch motor. When you activate the winch, the solenoid receives a signal from the control switch, which causes an electromagnetic field to be generated.

This, in turn, moves a metal plunger inside the solenoid. When the plunger moves, it completes the electrical circuit between the battery and the winch motor, allowing power to flow and the winch to start pulling. The solenoid works similar to how a relay does in your car.

When you turn the ignition key, the relay is activated, completing the circuit that allows the starter motor to start the engine. In the case of an ATV winch solenoid, it’s the control switch that activates the solenoid and allows power to flow to the winch motor. Why is it important to understand how the solenoid works? Well, knowing how it operates can help you troubleshoot any issues that may arise with your ATV winch.

If the winch is not responding or behaving erratically, it could be due to a faulty solenoid. By understanding how it functions, you can diagnose and fix the problem more effectively. In conclusion, an ATV winch solenoid acts as a switch that controls the flow of electrical current to the winch motor.

It works by generating an electromagnetic field that moves a metal plunger, completing the circuit and allowing power to flow. Understanding how the solenoid works is important for troubleshooting and maintaining the proper functioning of your ATV winch.

Section Two: Signs that your ATV winch solenoid may need testing

Have you noticed that your ATV winch isn’t working as well as it used to? It could be a sign that your winch solenoid needs testing. The winch solenoid is a critical component of your ATV’s winch system, responsible for controlling the power flow to the winch motor. If the solenoid is faulty or worn out, it can lead to issues like the winch not responding or struggling to operate properly.

To test the ATV winch solenoid, you can start by checking the connections and wiring for any signs of damage or corrosion. Next, you can use a multimeter to measure the voltage at the solenoid terminals while activating the winch switch. If the voltage reading is inconsistent or nonexistent, it’s a clear indication that the solenoid is faulty and needs replacement.

By testing and troubleshooting the ATV winch solenoid, you can ensure that your winch system is functioning at its best and ready for any off-road adventure.

Subsection 2.1: Common symptoms of a faulty solenoid

atv winch solenoid One of the important components of an ATV winch is the solenoid. It acts as an electrical switch, allowing power to flow to the winch motor. However, like any electrical component, solenoids can develop faults over time.

It’s important to be able to recognize the signs that your ATV winch solenoid may need testing. One common symptom of a faulty solenoid is when the winch fails to engage or disengage properly. You may notice that when you try to activate the winch, nothing happens, or it only works intermittently.

This could be a sign that the solenoid is not properly transmitting the electrical current to the motor. Another sign to watch out for is abnormal winch behavior. If you notice that your winch is working erratically, such as jerking or moving slowly, it could indicate a problem with the solenoid.

The solenoid is responsible for controlling the flow of power to the winch motor, so any issues with it can result in unpredictable winch performance. Additionally, a faulty solenoid can cause overheating. If you feel excessive heat coming from the solenoid or notice a burning smell, it’s essential to have it checked immediately.

Overheating can be a sign of a solenoid that is not functioning correctly, and ignoring this issue can lead to further damage to the winch or the electrical system. In conclusion, it’s crucial to be aware of the signs that your ATV winch solenoid may need testing. If you experience issues with winch engagement or disengagement, abnormal winch behavior, or overheating, it’s advisable to have a professional technician inspect and test the solenoid to ensure optimal performance and prevent further damage.

Subsection 2.2: Importance of regular testing

Regular testing of your ATV winch solenoid is crucial for a variety of reasons. Firstly, testing ensures that the solenoid is working properly and is ready to be used when you need it. Imagine being in a sticky situation where you need to use your winch to pull your ATV out of a difficult spot, only to find that the solenoid is faulty and won’t engage the winch.

Regular testing can help you identify any issues before they become major problems. Additionally, testing can help prolong the lifespan of your winch solenoid. By catching any potential issues early on, you can address them and prevent further damage.

This can ultimately save you time and money in the long run. So don’t neglect testing your ATV winch solenoid – it’s an important maintenance task that shouldn’t be overlooked.

Section Three: Tools needed for testing an ATV winch solenoid

Testing an ATV winch solenoid is crucial to ensure that it is functioning properly and will be reliable when you need it most. To test an ATV winch solenoid, you will need a few tools. First, you will need a multimeter to measure the continuity and resistance of the solenoid.

This will help you determine if there are any issues with the electrical connections or if the solenoid itself is faulty. You will also need a power source, such as a battery, to supply power to the solenoid during testing. Finally, you may need a wrench or screwdriver to disconnect and reconnect the electrical connections on the solenoid.

Once you have these tools ready, you can begin testing the ATV winch solenoid to ensure that it is in proper working order.

Subsection 3.1: List of necessary tools

When it comes to testing an ATV winch solenoid, there are a few tools that you will need to ensure a thorough and accurate diagnosis. One essential tool is a multimeter, which allows you to test for voltage, resistance, and continuity. This will help you determine if the solenoid is receiving power and functioning properly.

Another tool you will need is a test light, which can be used to check for power at various points in the electrical system. This can be particularly helpful in identifying any wiring issues. Additionally, a set of jumper wires can be useful for bypassing the solenoid and testing it directly.

This can help determine if the solenoid itself is faulty or if the issue lies elsewhere in the system. Lastly, having a good set of basic hand tools, such as screwdrivers and pliers, is always handy for removing and installing the solenoid. With these tools in hand, you will be well-equipped to test and troubleshoot your ATV winch solenoid.

Subsection 3.2: Importance of using the correct tools

correct tools, testing an ATV winch solenoid, importance of using correct tools In order to properly test an ATV winch solenoid, it is crucial to use the correct tools. Using the wrong tools can not only be ineffective in diagnosing any issues with the solenoid, but it can also be dangerous. One of the most important tools to have is a multimeter.

This device can measure the electrical current flowing through the solenoid and can help determine if it is functioning properly. Another tool that is essential is a voltage tester. This tool can be used to check the voltage levels in the solenoid and ensure that it is receiving the correct amount of power.

Additionally, having a set of screwdrivers and pliers can be useful for accessing the solenoid and making any necessary adjustments or repairs. By using the correct tools, you can ensure that the testing process is accurate and safe, ultimately leading to a properly functioning ATV winch solenoid.

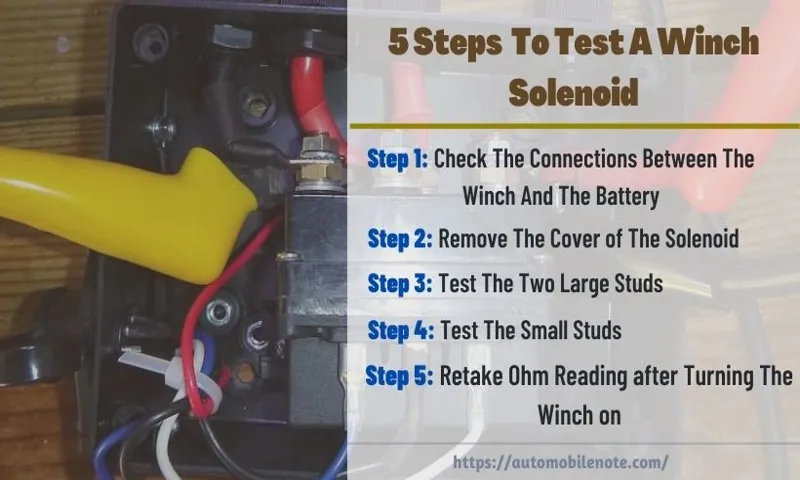

Section Four: Step-by-step guide on how to test an ATV winch solenoid

If you’re having trouble with your ATV winch not working properly, it could be due to a faulty solenoid. The solenoid is responsible for controlling the electrical current that runs through the winch motor, and if it’s not working correctly, your winch won’t function properly. Fortunately, you can test the solenoid to determine if it’s the source of the problem and fix it if needed.

Here’s a step-by-step guide on how to test an ATV winch solenoid. First, disconnect the power supply to the winch by removing the negative battery cable. This will ensure your safety while testing the solenoid.

Then, locate the solenoid on your ATV. It’s usually mounted near the battery or on the winch itself. Next, use a multimeter or a continuity tester to check the solenoid connections.

Start by testing the power input terminal, which is the one with the large cable connected to it. Place one probe on this terminal and the other probe on a suitable ground, like the ATV frame. If there is continuity, it means the power input terminal is working correctly.

Then, test the power output terminal, which is the one with the cable connected to the winch motor. Place one probe on this terminal and the other probe on a suitable ground. If there is continuity, it means the power output terminal is working correctly.

After that, test the control terminal, which is the one with the small wire connected to it. Disconnect the wire from the control terminal and connect one probe of the multimeter or continuity tester to the control terminal and the other probe to a suitable ground. Depress the winch switch or remote control button to activate the solenoid.

Subsection 4.1: Preparing for the test

To prepare for testing an ATV winch solenoid, there are a few steps you should follow. First, make sure that you have the necessary tools and equipment on hand, such as a multimeter and a set of wrenches. Next, locate the solenoid on your ATV.

It is typically mounted near the winch and connected to the battery and winch motor with electrical wires. Before testing the solenoid, it is important to disconnect the battery to avoid any potential electrical shock. Once you have disconnected the battery, you can use a wrench to remove the electrical wires from the solenoid.

Take note of which wire goes where, as it will be crucial for reassembly. After removing the wires, use a multimeter to check the resistance of the solenoid. This will help you determine if the solenoid is functioning properly.

A reading of zero resistance may indicate a short circuit, while a reading of infinite resistance may suggest an open circuit. You should also check the continuity between the power terminals of the solenoid to ensure that it is not damaged. Once you have completed these tests, you can reassemble the solenoid and reconnect the battery to see if the winch operates correctly.

By following these steps, you can effectively test an ATV winch solenoid and determine if it needs to be repaired or replaced.

Subsection 4.2: Testing the solenoid’s coil

atv winch solenoid coil, test atv winch solenoid coil. In this section, we will focus on how to test the coil of an ATV winch solenoid. The coil is an essential component of the solenoid and plays a crucial role in the functioning of the winch.

Testing the coil is necessary when troubleshooting a winch problem or when trying to determine if the solenoid is the cause of the issue. To test the solenoid’s coil, you will need a multimeter set to the resistance or ohms mode. Start by disconnecting the power source from the solenoid to ensure your safety.

Then, locate the two terminals for the coil on the solenoid. These terminals are usually marked with an “A” and a “B.” Take the multimeter probes and touch one probe to each of the coil terminals.

Make sure the probes have a good connection with the terminals. Once you have a good connection, the multimeter should display the resistance value of the coil. A healthy coil should have a resistance within a specific range, typically indicated in the solenoid’s specifications.

If the resistance value falls within this range, it means that the coil is functioning correctly. However, if the resistance value is outside of the specified range or shows as open (“OL”) on the multimeter, it indicates a problem with the coil. If the coil resistance is too high, it could mean that the coil is damaged, or there is a loose connection.

On the other hand, if the resistance value shows as zero or near zero, it suggests a short circuit in the coil. In either case, if the coil is faulty, it will need to be replaced. Fortunately, replacing the coil is relatively straightforward, and many ATV winch solenoids have replaceable coils that can be easily purchased online or from a dealer.

Subsection 4.3: Testing the solenoid’s contacts

Testing the solenoid’s contacts is an important step in diagnosing and resolving issues with an ATV winch. The solenoid is responsible for controlling the flow of electricity to the winch motor, so if there are any problems with the contacts, it can cause the winch to malfunction or not work at all. To test the solenoid’s contacts, you will need a multimeter.

Start by disconnecting the winch from the battery to ensure safety. Then, locate the solenoid and remove the cover if necessary. Using the multimeter set to the resistance (ohms) setting, touch one probe to the battery terminal and the other probe to the contact terminal on the solenoid.

A reading of zero or low resistance indicates that the contacts are functioning properly. However, if the reading is high or infinite resistance, it means there is a problem with the contacts and they will need to be cleaned or replaced. Testing the solenoid’s contacts is a simple yet essential step in troubleshooting and maintaining an ATV winch.

Subsection 4.4: Troubleshooting potential issues

troubleshooting potential issues, ATV winch solenoid, step-by-step guide, test, problems, solution, functionality

Section Five: Understanding the test results

So, you’ve just installed an ATV winch solenoid and you want to make sure it’s working properly. Well, lucky for you, there are a few simple tests you can do to check its functionality. First, you’ll want to inspect the wiring connections on the solenoid.

Make sure they are secure and free from any fraying or damage. Next, you’ll want to use a multimeter to test the continuity of the solenoid. Set the multimeter to the resistance setting and touch the probes to the terminals on the solenoid.

If the multimeter reads a low resistance value, then the solenoid is functioning properly. If the multimeter reads a high resistance value or no value at all, this may indicate a faulty solenoid. Another test you can perform is a voltage test.

Use the multimeter and set it to the voltage setting. Connect the probes to the positive and negative terminals on the solenoid. Activate the winch and check the voltage reading on the multimeter.

If the voltage reading is close to the battery voltage, then the solenoid is working correctly. If there is no voltage reading or an inconsistent reading, then the solenoid may need to be replaced. Remember to always consult the manufacturer’s instructions for proper testing procedures specific to your ATV winch solenoid.

Happy testing!

Subsection 5.1: Interpreting a successful test

When it comes to interpreting the results of a successful test, there are a few key factors to consider. Firstly, it’s important to look at the overall performance of the test and determine whether it met the goals and objectives that were set forth. This involves analyzing the data and metrics collected during the test and comparing them to the desired outcomes.

Additionally, it’s also important to consider the context in which the test was conducted. Factors such as the target audience, the timing of the test, and any external influences can all impact the results and should be taken into account when interpreting the findings. Finally, it’s crucial to consider the implications of the test on future decision-making.

A successful test can provide valuable insights and inform future strategies, so it’s important to take the time to analyze and understand the results fully. By doing so, you can ensure that the success of the test is not just a one-time occurrence, but rather a stepping stone towards continued growth and improvement.

Subsection 5.2: Interpreting a failed test

When it comes to software testing, it’s not uncommon for tests to fail. While it can be frustrating, it’s important to approach these failures with a calm and analytical mindset. Interpreting a failed test involves looking beyond the surface level and digging deeper to understand the root cause of the failure.

This process requires examining the test data, analyzing any error messages or logs, and considering other factors that could have influenced the result. It’s also essential to consider the context of the test, such as the specific requirements or conditions it was designed to evaluate. By taking a thorough and systematic approach to interpreting a failed test, developers and testers can gain valuable insights that will help them rectify the issue and improve the overall quality of the software.

Conclusion: Importance of regular testing and maintenance

In conclusion, testing an ATV winch solenoid can be as simple as giving it a little shock therapy. Just like a doctor testing your reflexes with a rubber mallet, you can test your winch solenoid by giving it a little jolt of electricity. If it jumps or twitches, congratulations – your solenoid is in good health! But if it just sits there like a lump, well, it might be time to go shopping for a new one.

So remember, when it comes to testing your ATV winch solenoid, a little zap is all you need to determine its condition. And who knows, maybe your winch solenoid just needs a little shock therapy to get its groove back. Now go forth, my adventurous friends, and conquer those off-road obstacles with the confidence that your winch solenoid is ready to save the day!”

Appendix: Additional resources and troubleshooting tips

If you’re having trouble with your ATV winch solenoid and need to know how to test it, don’t worry – there are several resources and troubleshooting tips available to help you. One way to test the solenoid is by using a multimeter, which can measure the electrical resistance of the solenoid. You can follow the steps outlined in the user manual or check online resources for guidance.

Additionally, there are many helpful videos on platforms like YouTube that provide step-by-step instructions on how to test an ATV winch solenoid. If you’re still having trouble after trying these methods, it may be best to consult a professional who can diagnose and fix the issue for you. Remember, troubleshooting any electrical component can be complex, so don’t hesitate to seek expert help if needed.

FAQs

What is an ATV winch solenoid and what is its function?

An ATV winch solenoid is a switch that controls the power to the winch motor. When activated, it allows the flow of electricity to the motor, enabling the winch to pull or release the cable.

How can I test an ATV winch solenoid for proper operation?

To test an ATV winch solenoid, you can use a multimeter to measure the continuity of the solenoid’s terminals. Simply disconnect the power source, remove the solenoid from the circuit, and use the multimeter’s continuity test to check if the solenoid is functioning correctly.

What are some common signs of a faulty ATV winch solenoid?

Some common signs of a faulty ATV winch solenoid include the winch not responding to the controls, the winch only working in one direction, or a clicking sound coming from the solenoid when the winch is activated.

Can a faulty ATV winch solenoid be repaired, or does it need to be replaced?

In some cases, a faulty ATV winch solenoid can be repaired by cleaning the contacts or replacing damaged components. However, if the solenoid is severely damaged or corroded, it is usually best to replace it with a new one.

How do I safely replace an ATV winch solenoid?

To safely replace an ATV winch solenoid, first, disconnect the power source and remove the old solenoid from the winch. Take note of the wiring connections before disconnecting them. Then, connect the wiring to the new solenoid, making sure to match the terminals correctly. Finally, reattach the solenoid to the winch and reconnect the power source.

What are some tips for maintaining an ATV winch solenoid?

To maintain an ATV winch solenoid, regularly inspect it for any signs of damage or corrosion. Clean the terminals and contacts with electrical contact cleaner if needed. Also, make sure to follow the manufacturer’s recommendations for lubricating the solenoid and keeping it protected from water and dirt.

Is it necessary to replace an ATV winch solenoid with a specific brand or model?

While it is generally recommended to replace an ATV winch solenoid with the same brand or model that is compatible with your winch, there are often aftermarket options available that can work as well. It is important to ensure that the replacement solenoid has the same electrical specifications as the original one.