So you’ve got yourself a power inverter and you’re excited to start using it to power your electronic devices on the go. But before you dive in and start plugging things in, there’s an important step you’ll need to take: grounding your power inverter. But what exactly does that mean, and why is it necessary? Think of grounding your power inverter as creating a safe pathway for electrical energy to flow.

When your inverter is connected to a power source, it converts the DC power into AC power, which can then be used to power your devices. However, in the process of converting the power, there is a risk of electrical surges. These surges can be dangerous, not only to your devices but also to you.

Grounding your power inverter provides a way for these surges to safely dissipate into the ground, protecting both your devices and yourself. It acts as a safeguard against potential electrical hazards, such as electric shock or fires. So how exactly do you go about grounding your power inverter? Well, it’s actually a fairly straightforward process.

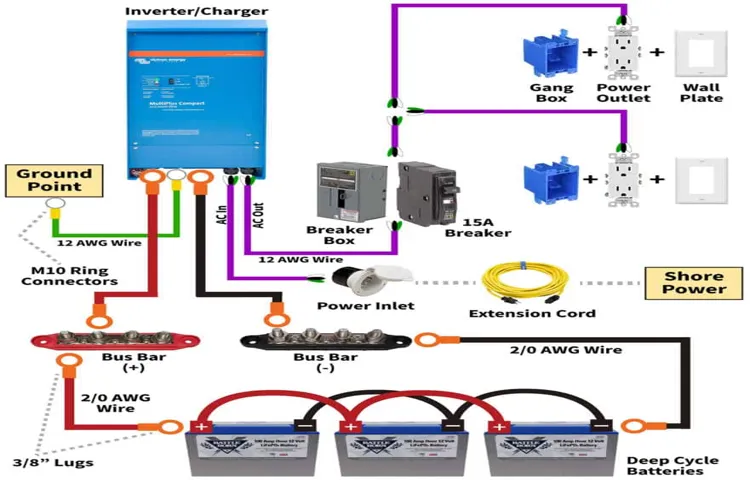

Most power inverters come with a grounding lug or terminal that you can use to connect a grounding wire. This grounding wire should then be connected to a solid ground, such as a metal rod driven into the earth. This will create a direct path for any electrical surges to safely dissipate.

By taking the time to properly ground your power inverter, you can ensure that you’ll be able to safely use your devices without any unnecessary risks. It’s a small step that can make a big difference in protecting both your devices and yourself. So before you start plugging things in and enjoying the convenience of portable power, don’t forget to ground your power inverter!

Table of Contents

Introduction

Are you looking to learn how to ground a power inverter? Good news, you’re in the right place! Grounding a power inverter is an important step to ensure safety and prevent electrical shocks. When a power inverter is not properly grounded, it can create a potential hazard. Grounding the inverter involves connecting it to a grounding system, typically the same grounding system used for your residential or commercial electrical system.

This helps to redirect any stray current that may occur during the operation of the inverter. It’s important to consult the manufacturer’s instructions for your specific inverter model and follow their guidelines for proper grounding. Additionally, you should consider enlisting the help of a qualified electrician to ensure the grounding process is done correctly.

So, before you start using your power inverter, make sure it’s properly grounded for your safety and peace of mind.

What is a power inverter?

power inverter

Why is grounding important?

grounding, importance, electrical safety

Benefits of properly grounding a power inverter

Benefits of properly grounding a power inverter Introduction: Power inverters are devices that convert direct current (DC) electricity from a battery into alternating current (AC) electricity that can be used to power various appliances and devices. Properly grounding a power inverter is essential for ensuring safety and maximizing its efficiency. Grounding refers to the process of connecting the inverter to a grounded metal object or earth to provide a safe path for electrical currents to flow in case of a fault or surge.

In this blog post, we will explore the benefits of properly grounding a power inverter.

Step 1: Choosing the right location

If you’re looking to power your electronics on the go, a power inverter can be a handy tool. But one of the first steps in installing a power inverter is choosing the right location for it. This is important because the location you choose will determine how well the inverter functions and how easily it can be accessed.

When choosing a location for your power inverter, there are a few things to consider. First, you’ll want to find a spot that is easily accessible, preferably near your vehicle’s battery. This will make it easier to connect the inverter to the battery and minimize the amount of wiring you need to do.

Next, you’ll want to choose a location that is well-ventilated. Power inverters can generate a fair amount of heat, so you’ll want to make sure there is enough airflow to keep the inverter cool. This can help prevent overheating and ensure the longevity of your inverter.

Additionally, you’ll want to choose a location that is protected from the elements. Power inverters are not waterproof, so you’ll want to make sure they are kept in a location where they won’t be exposed to rain or snow. This will help to prevent any damage to the inverter and keep it functioning properly.

Overall, choosing the right location for your power inverter is an important step in the installation process. By considering accessibility, ventilation, and protection from the elements, you can ensure that your inverter functions properly and lasts for a long time. So take the time to find the perfect spot for your power inverter and enjoy the convenience of powering your electronics on the go.

Finding a suitable surface for mounting the inverter

The first step in mounting an inverter is to find a suitable surface for installation. Choosing the right location is crucial for ensuring the inverter functions properly and is easily accessible for maintenance and repairs. When selecting a surface, there are a few important considerations to keep in mind.

First, the surface should be sturdy and able to support the weight of the inverter. This is especially important if the inverter is large or heavy. Additionally, the surface should be level and flat to ensure proper alignment and stability.

It’s also important to choose a location that is well-ventilated to prevent the inverter from overheating. Finally, consider the proximity to the electrical supply and other equipment, as this can impact the efficiency and effectiveness of the inverter. By carefully selecting the right location, you can ensure that your inverter is securely mounted and functions optimally.

Considering proximity to the battery and other electrical components

When it comes to choosing the right location for your electrical components, proximity to the battery is a crucial factor to consider. You want to ensure that you place the components in a location that is easily accessible and close to the battery. This not only makes it easier for you to connect and disconnect the components, but it also reduces the length of the wiring needed, minimizing the risk of any electrical interference or loss of power.

Additionally, being in close proximity to the battery also allows for better heat dissipation, as the battery itself generates heat during operation. By placing the components near the battery, you can take advantage of the battery’s natural cooling properties and reduce the risk of overheating. Another consideration is the proximity to other electrical components.

Placing your components too close to other electrical components can increase the risk of interference and signal loss. It’s important to maintain a safe distance between the components to ensure optimal performance and reduce the risk of electrical issues. So, when choosing the right location for your electrical components, make sure to take into account the proximity to the battery and other electrical components for the best results.

Step 2: Preparing the grounding wire

Now that you have gathered all the necessary materials for grounding your power inverter, let’s move on to the second step. Preparing the grounding wire is an important part of the process to ensure the safety and reliability of your power inverter. First, you will need to determine the length of grounding wire you will need.

This will depend on the distance between your power inverter and the grounding point, such as a metal rod driven into the ground. Make sure to measure carefully to avoid any unnecessary wire waste. Next, strip the insulation from both ends of the grounding wire.

This will expose the bare copper wire, which is necessary for a proper electrical connection. You can use wire strippers or a utility knife to carefully remove the insulation, taking care not to damage the wire itself. Once the wire is stripped, attach one end of the wire to the grounding point.

This could be a grounding lug on the power inverter or a separate grounding point nearby. Make sure to secure the wire tightly, using a screw or nut to hold it in place. Finally, attach the other end of the grounding wire to the metal chassis of the power inverter.

This ensures that any potential electrical faults are safely directed to the grounding point, protecting both the power inverter and any connected devices. Remember, proper grounding is essential for the safe and effective operation of your power inverter. By following these steps to prepare the grounding wire, you can ensure that your power inverter is properly grounded and ready to use.

Selecting the correct wire gauge

In Step 2 of selecting the correct wire gauge for your electrical project, we’ll guide you through preparing the grounding wire. The grounding wire is an important part of the electrical system as it provides a path for electrical current to safely disperse in the event of a fault or surge. To prepare the grounding wire, you’ll need to strip the insulation off the ends of the wire using wire strippers.

Make sure to strip off enough insulation to expose the bare copper wire. You’ll also want to twist the exposed strands of the wire together to create a tightly bound end. This will ensure a secure connection when attaching the wire to the grounding terminal.

Remember, a solid and reliable grounding system is essential for protecting both people and equipment from electrical hazards, so be sure to follow proper safety guidelines while working with electrical wires.

Determining the length of the grounding wire

grounding wire, length of grounding wire

Properly stripping and crimping the wire ends

In Step 2 of preparing the grounding wire, it is crucial to properly strip and crimp the wire ends. This ensures a secure and efficient electrical connection. Stripping the wire involves carefully removing the insulation from the ends to expose the bare wire.

This can be done using wire strippers or a utility knife. It’s important to strip just enough insulation to expose the wire without damaging it. Once the wire ends are stripped, crimping is the next step.

Crimping involves compressing the wire onto a connector or terminal using a crimping tool. This creates a tight and secure connection that allows for a smooth flow of electricity. When crimping, ensure that the wire is properly positioned and that the crimping tool is applied with sufficient force.

This will guarantee a solid and reliable electrical connection. Remember, taking the time to properly strip and crimp the wire ends will result in a safe and effective grounding system for your electrical project.

Step 3: Connecting the grounding wire

After properly mounting your power inverter and ensuring all electrical connections are secure, it’s time to move on to the next crucial step in the grounding process: connecting the grounding wire. The grounding wire provides a path for excess electrical current to safely dissipate into the ground, minimizing the risk of electrical shock and potential damage to your power inverter. To begin, locate the grounding terminal on your power inverter.

This terminal is typically marked with a symbol resembling a lightning bolt or the word “ground.” Next, prepare the grounding wire by stripping the insulation from the end, exposing the bare copper wire. Insert the stripped end of the wire into the grounding terminal and tighten the screw to secure it in place.

If your power inverter is equipped with a grounding lug, attach the grounding wire to the lug using a screw or bolt. Finally, connect the other end of the grounding wire to a suitable grounding point, such as a metal stake driven into the earth or a designated grounding rod. It’s important to ensure this grounding point is located within close proximity to your power inverter for the most effective grounding.

Remember to always consult your power inverter’s instruction manual for specific guidance on grounding procedures, as different models may have varying requirements. By properly connecting the grounding wire, you can ensure the safe and efficient operation of your power inverter.

Locating a suitable grounding point on the vehicle

grounding wire, vehicle, suitable grounding point

Ensuring a secure and reliable connection

grounding wire, secure connection

Step 4: Testing the grounding

When it comes to using a power inverter, it’s crucial to make sure it is properly grounded. Grounding your power inverter not only ensures safety but also helps to prevent electrical hazards. To test the grounding of your power inverter, you’ll need a multimeter.

Start by disconnecting all power sources to the inverter. Then, set your multimeter to the resistance (ohms) setting. Place the red probe on the grounding point of the inverter and the black probe on a known ground, such as a metal pipe or a grounding rod.

If the multimeter reads a very low resistance, close to zero, it means that the ground connection is good. However, if you get a high resistance reading or it shows “OL” (open line), it means that the grounding is not proper and you should take necessary steps to improve it. Remember, a properly grounded power inverter not only protects your electronic devices but also provides a safe working environment.

Using a multimeter to check for a proper ground

multimeter, check, proper ground, testing, grounding In order to ensure electrical safety and prevent potential hazards in your home or workspace, it is important to test the grounding of your electrical outlets. One effective way to do this is by using a multimeter. A multimeter is a versatile tool that can measure electrical voltage, current, and resistance.

When testing for a proper ground, you will be checking for a continuity of electrical flow between the ground prong of the outlet and a known earth ground. First, make sure the multimeter is set to the continuity test mode. Then, insert the black probe into the ground slot of the outlet and the red probe into a known earth ground, such as a metal water pipe or a grounding rod.

If the multimeter beeps or indicates continuity, it means that the outlet is properly grounded. However, if there is no beep or continuity, it indicates that the ground connection is faulty or non-existent. In such a case, it is recommended to call a certified electrician to investigate and fix the issue.

Testing the grounding is an essential step in maintaining electrical safety, and using a multimeter can make this task quick and easy. So, don’t overlook this crucial aspect and ensure that your outlets have a proper ground connection.

Verifying continuity in the ground circuit

In order to ensure the safety and functionality of electrical circuits, it’s important to verify the continuity in the ground circuit. This is a crucial step in troubleshooting any electrical issues and can help prevent potential hazards. To test the grounding, you will need a digital multimeter or a continuity tester.

Start by disconnecting the power source to the circuit you are testing. Then, set your multimeter or continuity tester to the continuity mode. Touch one probe to the grounding conductor and the other probe to a known ground, such as a metal water pipe or a ground rod.

If there is continuity, it means that the ground circuit is properly connected and functioning. If there is no continuity, it indicates a break or open circuit in the ground wiring, which needs to be fixed before restoring power to the circuit. Testing the grounding is an essential part of any electrical maintenance or troubleshooting process and should not be overlooked.

Conclusion

In conclusion, grounding a power inverter is like giving it a strong cup of coffee to start its day. Just like how caffeine helps us focus and stay grounded, a properly grounded power inverter ensures that it can stay focused and grounded in its electrical operations. By providing a safe path for electrical surges to be redirected, grounding the power inverter acts as its own personal Zen master, keeping it in balance and preventing any shocking surprises.

So, remember to give your power inverter its daily dose of grounding – it’s the electrifying secret to a stable and harmonious electrical system!

The importance of grounding a power inverter

power inverter, grounding, importance

Ensuring a safe and efficient operation

In order to ensure a safe and efficient operation, it is crucial to test the grounding. Grounding refers to the process of providing an electrical connection to the earth, which helps to prevent electrical shock and ensure the proper functioning of electrical equipment. Testing the grounding system involves measuring the resistance between the electrical system and the earth to ensure that it is within acceptable limits.

This is important because if the resistance is too high, it can lead to an unsafe buildup of electrical energy, while if it is too low, it can cause electrical equipment to malfunction or even fail. Testing the grounding system is a critical step in ensuring that the electrical system is safe and that it will operate efficiently without any issues.

FAQs

What is a power inverter and what does it do?

A power inverter is a device that converts DC (direct current) power from a battery or solar panel into AC (alternating current) power that can be used to run household appliances. It is commonly used in off-grid and emergency power situations.

How does a power inverter work?

A power inverter works by using electronic components to convert the DC power input into AC power output. It uses switches and transformers to convert the voltage and change the direction of the current to match the AC power requirements.

Can I use a power inverter in my car?

Yes, you can use a power inverter in your car to power devices or charge electronics. However, it’s important to check the power rating of your car’s electrical system and the power requirements of the devices you wish to use to ensure compatibility.

How do I connect a power inverter to a battery?

To connect a power inverter to a battery, you will need to use appropriate cables and connectors. You will need to connect the positive terminal of the inverter to the positive terminal of the battery, and the negative terminal of the inverter to the negative terminal of the battery.

What are the safety considerations when using a power inverter?

When using a power inverter, it is important to follow safety guidelines. This includes ensuring the inverter is properly grounded, using the correct cables and connectors, and avoiding overloading the inverter. It’s also important to avoid using the inverter in wet or damp conditions.

Can a power inverter damage my electronics?

If not used correctly, a power inverter can potentially damage sensitive electronics. It’s important to ensure that the power inverter you use is of high quality, provides clean and stable power, and has appropriate voltage and power ratings for your devices.

How can I ground a power inverter?

Grounding a power inverter is important for safety reasons. To ground a power inverter, you can connect a grounding wire from the inverter’s grounding terminal to a suitable grounding point, such as the metal chassis of the vehicle or a grounding rod installed nearby. It’s recommended to follow the manufacturer’s instructions for specific grounding requirements.