Have you ever found yourself in a situation where your power tool battery died right in the middle of a project? It’s frustrating, isn’t it? Luckily, there’s a solution that can ensure you never have to deal with this inconvenience again – an inverter for power tool batteries. But with so many different sizes and options available, how do you choose the right one for your needs? Let’s dive in and explore the factors to consider when selecting the perfect size inverter for power tool batteries. Think of it like choosing the right-sized socket wrench for a specific bolt – you want the fit to be just right.

Just like how using the wrong size wrench can lead to stripped bolts or damaged nuts, using an inverter that’s too small or too large can have negative consequences for your battery-powered tools. But fear not, because armed with the right information, you’ll be well-equipped to make an informed decision and keep your power tools running smoothly.

Table of Contents

Understanding Power Tool Battery Chargers

When it comes to charging power tool batteries, the size of the inverter you need depends on a few factors. First, you’ll want to consider the voltage and amperage requirements of your power tool batteries. This information is usually found on the battery itself or in the tool’s user manual.

Once you have this information, you can determine the wattage required to charge your batteries. To calculate the wattage, simply multiply the voltage by the amperage. For example, if your power tool batteries require 18 volts and 5 amps, the wattage would be 90 watts.

In this case, you would need an inverter with a wattage rating equal to or greater than 90 watts to charge your batteries efficiently. It’s important to choose an inverter that can handle the wattage requirements of your power tool batteries, as using an undersized inverter can lead to slower charging times or even damage to the inverter itself.

How do power tool battery chargers work?

power tool battery chargers, understanding power tool battery chargers Power tool battery chargers are an essential component for any DIY enthusiast or professional tradesperson. But have you ever wondered how they actually work? Well, let’s dive in and unravel the mystery. Essentially, power tool battery chargers are designed to recharge the batteries used in power tools such as drills, saws, and sanders.

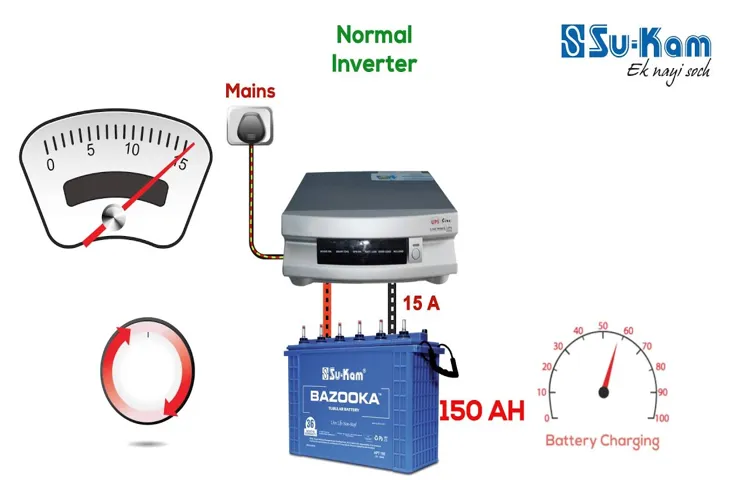

These chargers typically consist of a power input, an internal circuitry, and a charging port. When you connect the charger to a power source, it converts the AC (alternating current) electricity from the outlet into DC (direct current) power that is suitable for charging the batteries. The internal circuitry in the charger plays a crucial role in effectively and safely charging the batteries.

It monitors the voltage and current flow to ensure that the charging process is optimized and does not damage the battery. Most chargers today come with advanced features such as temperature detection and overcharge protection to prevent overheating and extend the battery life. When you connect your power tool battery to the charger, it is important to match the voltage and compatibility requirements specified by the manufacturer.

This ensures that the charger delivers the correct amount of current and charging rate for your specific battery. During the charging process, the charger supplies a steady current to the battery, gradually replenishing the energy stored inside it. The charger controls the charging rate based on the battery’s state of charge, allowing it to charge efficiently without overloading or undercharging.

Once the battery is fully charged, the charger switches to a trickle charge mode to maintain the battery’s charge level and prevent overcharging. Some chargers even have a built-in indicator or LED lights that indicate when the battery is fully charged, making it convenient for users to know when to disconnect the charger. In conclusion, power tool battery chargers work by converting AC electricity into DC power and regulating the voltage and current flow to safely charge the batteries.

Understanding how these chargers work can help you maximize the performance and lifespan of your power tools. So the next time you plug in your charger, you can appreciate the science behind it and the convenience it brings to your DIY projects.

What factors do you need to consider when choosing an inverter size?

power tool battery charger

Calculating Power Tool Battery Charger Wattage

If you’re wondering what size inverter you need to charge your power tool batteries, it’s important to understand the wattage requirements of your charger. Power tool batteries typically have a charger that converts household AC power to the DC power that the battery needs. The charger will have a power rating, often given in watts, which indicates how much power it can deliver to the battery.

To determine the wattage requirements for your charger, you can check the label or manual that came with your charger. Once you know the charger’s wattage, you can choose an inverter that can provide at least that amount of power. It’s always a good idea to choose an inverter with a slightly higher wattage rating to accommodate any power spikes or fluctuations.

Determining the wattage of your power tool battery charger

power tool battery charger wattage, determining wattage, calculating wattage, power tool battery charger, determine wattage of power tool battery charger, how to calculate wattage of power tool battery charger

Calculating the total wattage for multiple chargers

calculating power tool battery charger wattage. When it comes to power tool battery chargers, it’s important to make sure you have the right wattage to properly charge your batteries. The wattage of a charger determines how quickly it can charge your battery and how much power it can provide.

To calculate the total wattage for multiple chargers, you simply add up the wattages of each individual charger. For example, let’s say you have three power tool battery chargers. Charger A has a wattage of 50, Charger B has a wattage of 75, and Charger C has a wattage of 100.

To calculate the total wattage, you would add 50 + 75 + 100, which gives you a total of 225 watts. It’s important to note that the total wattage is the maximum amount of power that all the chargers combined can provide. So if you have multiple chargers plugged in and charging at the same time, the total wattage will determine how quickly your batteries can be charged.

Calculating the total wattage is important because if you exceed the wattage capacity of your power source, you could overload the circuit and cause damage. It’s always best to check the wattage capacity of your power source and make sure it can handle the total wattage of your chargers. In conclusion, when calculating the total wattage for multiple power tool battery chargers, simply add up the wattages of each individual charger.

This will give you the total amount of power that your chargers can provide. By making sure you have the right wattage, you can properly charge your batteries without causing any damage to your power source.

Choosing the Right Size Inverter

When it comes to charging power tool batteries, choosing the right size inverter is crucial. An inverter is a device that converts the DC (direct current) power from a battery into AC (alternating current) power that can be used to run tools or charge batteries. The size of the inverter you need will depend on the power requirements of your tools and the amount of time you want to be able to use them.

A larger inverter will be able to handle more power and run tools for longer periods of time, while a smaller inverter may be sufficient if you only need to charge batteries occasionally or run smaller tools. It’s important to consider both the wattage and the surge capacity of the inverter to ensure it can handle the power demands of your tools. So, before you make a purchase, be sure to check the specifications of your power tools and choose an inverter that can meet their needs.

Determining the surge or peak wattage

“Choosing the Right Size Inverter” When it comes to choosing the right size inverter for your needs, it’s important to consider the surge or peak wattage. This refers to the amount of power the inverter can handle in short bursts. So, if you have appliances or devices that require a lot of power when they first turn on, such as refrigerators or air conditioners, you’ll want to make sure your inverter can handle the surge wattage.

To determine the surge or peak wattage, take a look at the specifications of the appliances or devices you plan to power with the inverter. Look for information on the starting or surge wattage. This is usually higher than the running or continuous wattage, as appliances require more power when they first start up.

Once you have the starting or surge wattage for each appliance or device, add them all together. This will give you an idea of the total surge wattage you need your inverter to handle. It’s always a good idea to choose an inverter with a slightly higher surge wattage rating than you think you’ll need, to ensure that it can handle any unexpected power surges or spikes.

In addition to surge wattage, you’ll also need to consider the continuous or running wattage of the appliances or devices you plan to power. This is the average amount of power they require to operate. Make sure the inverter you choose can handle the total continuous wattage of all your appliances or devices.

By taking into account both the surge and continuous wattage requirements of your appliances or devices, you can choose the right size inverter that will meet your power needs. Don’t forget to also consider factors such as the quality and reliability of the inverter, as well as any additional features or functions you may need. Happy inverter shopping!

Selecting an inverter with sufficient continuous wattage

choosing the right size inverter

Common Inverter Sizes for Power Tool Battery Chargers

If you’re looking to charge power tool batteries using an inverter, it’s important to determine the right size to ensure efficient and effective charging. The size of the inverter you’ll need depends on the power requirements of your power tool battery charger. In general, power tool batteries require anywhere from 12V to 18V for charging.

So, you’ll need an inverter with an output voltage that matches your charger’s requirements. Additionally, you’ll need to consider the power capacity of your charger, which is usually expressed in watts. To determine the appropriate inverter size, multiply the charger’s voltage requirement by its wattage.

For example, if your charger requires 12V and 100 watts, you’ll need an inverter that can deliver at least 12V and 100 watts. Keep in mind that it’s always a good idea to choose an inverter with a slightly higher wattage capacity to accommodate any additional power demands or fluctuations.

300-watt inverter

power tool battery chargers, inverter sizes, 300-watt inverter In the world of power tools, having a reliable battery charger is a must. But what if you find yourself in a situation where there is no access to power? This is where inverters come in handy. An inverter is a device that converts DC power from a battery into AC power, allowing you to power your tools even when you don’t have access to an electrical outlet.

When it comes to choosing the right inverter for your power tool battery charger, one common size is the 300-watt inverter. This size is often suitable for charging battery-operated power tools such as drills, saws, and sanders. The 300-watt inverter is compact and portable, making it ideal for on-the-go use.

It’s also powerful enough to handle the charging needs of most power tools, giving you the flexibility to use your tools wherever you need them. So, if you’re looking for a reliable and efficient way to charge your power tool batteries on the go, a 300-watt inverter is definitely worth considering.

600-watt inverter

power tool battery chargers When it comes to charging your power tool batteries on the go, having the right inverter size is crucial. One common inverter size for power tool battery chargers is the 600-watt inverter. This size is perfect for charging smaller power tools, such as drills and saws, as it provides enough power to charge their batteries without overloading the inverter.

The 600-watt inverter can also handle other low-power devices, like laptops and cell phones, making it a versatile option for those who need to charge multiple devices at once. With its compact size and efficient power output, the 600-watt inverter is a popular choice among DIY enthusiasts and professionals alike. Whether you’re working on a construction site or tackling a home improvement project, having a reliable inverter like the 600-watt model ensures that your power tools are always ready to go.

So, if you’re in the market for a new inverter for your power tool battery charger, consider the 600-watt size for all your charging needs. It’s a compact, powerful, and reliable option that won’t let you down.

1000-watt inverter

power tool battery chargers

1500-watt inverter

1500-watt inverter, power tool battery chargers

Conclusion

So, you’re wondering what size inverter you need to charge your power tool batteries? Well, it’s not as simple as just picking a random size and hoping for the best. You see, power tool batteries come in all shapes and sizes, just like the tools themselves. And that means they require different amounts of power to charge.

Think of it like trying to find the perfect pair of shoes. You wouldn’t wear a size 10 if you’re a size 7, would you? It just wouldn’t fit properly and you’d end up uncomfortable and frustrated. The same goes for your inverter.

You need to find the right size to properly support and charge your batteries. But fear not, my savvy friend, for I have a handy solution for you. Instead of going on a wild goose chase trying to match the inverter to each individual battery, why not opt for a slightly larger size? It’s like buying a pair of shoes that are a size too big – they may not fit perfectly, but they’ll still get the job done.

So, the key here is to find an inverter that is slightly larger than what you think you’ll need. This way, you won’t be left in the dark (literally) if you happen to acquire a power tool with a larger battery down the road. It’s all about future-proofing your charging capabilities, my friend.

In conclusion, when it comes to choosing the right size inverter to charge your power tool batteries, it’s best to err on the side of caution and go for a slightly larger size. Trust me, your batteries – and your projects – will thank you for it. Happy charging!”

Determining the right size inverter for your power tool battery charger ensures efficient charging and prevents damage to your charger or batteries.

When it comes to finding the right size inverter for your power tool battery charger, there are a few things to consider. The inverter size refers to its power output, which is measured in watts. To ensure efficient charging and prevent damage to your charger or batteries, it’s important to choose an inverter that can handle the power requirements of your charger.

A common mistake is selecting an inverter that is too small, which can lead to slower charging times or even damage to the charger. On the other hand, choosing an inverter that is too large may not be necessary and can result in wasted energy. To determine the right size inverter, start by checking the power requirements of your charger.

This information can usually be found on the charger itself or in the user manual. Once you know the power requirements, choose an inverter that can provide at least that amount of power, with some extra capacity to account for any power surges or fluctuations. By selecting the right size inverter for your power tool battery charger, you can ensure efficient and effective charging every time.

FAQs

What size inverter do I need to charge power tool batteries?

The size of the inverter you need to charge power tool batteries will depend on the power requirements of your specific tools. It is recommended to check the power consumption of each tool and add up their wattage to determine the minimum size inverter you should use.

Can I use a small inverter to charge power tool batteries?

Yes, you can use a small inverter to charge power tool batteries as long as the inverter can handle the wattage requirements of the tools. However, keep in mind that a smaller inverter may take longer to charge the batteries compared to a larger one.

What are the advantages of using an inverter to charge power tool batteries?

Using an inverter to charge power tool batteries allows you to have portable charging capabilities. You can easily charge your batteries on the go, without needing access to a traditional power outlet. This is especially useful for outdoor or remote work sites.

Can I charge multiple power tool batteries at once using an inverter?

Yes, you can charge multiple power tool batteries at once using an inverter, as long as the inverter has sufficient wattage to handle the combined power requirements of the batteries. Be sure to check the wattage of each tool and add them up to ensure the inverter can handle the load.

Are there any safety precautions I should take when using an inverter to charge power tool batteries?

When using an inverter to charge power tool batteries, ensure that the inverter is properly grounded and that the batteries are connected correctly. It is also important to use the appropriate cables and connectors to prevent any power surges or overheating.

Can I use a modified sine wave inverter to charge power tool batteries?

Yes, you can use a modified sine wave inverter to charge power tool batteries. However, keep in mind that some power tools may not operate as efficiently or may experience a slight decrease in performance when charged with a modified sine wave inverter compared to a pure sine wave inverter.

Do I need to have a deep cycle battery to use with an inverter for charging power tool batteries?

While it is not mandatory to have a deep cycle battery, it is recommended. Deep cycle batteries are designed to handle frequent charging and discharging, making them more suitable for use with power tools. They provide a longer-lasting and more reliable power source compared to regular automotive batteries.