If you’re a DIY mechanic or just someone who likes to take care of your car, then you know how important it is to keep your wheel bearings well lubricated. A wheel bearing greaser can make the job easier, faster and more efficient. But how exactly do you use it? In this post, we’ll guide you through step-by-step on how to use a wheel bearing grease packer.

Whether you’re a beginner or a seasoned pro, this guide will help you get the job done right the first time. So, grab your wheel bearing greaser and let’s get started!

Table of Contents

What is a Wheel Bearing Grease Packer?

If you’re wondering how to use a wheel bearing grease packer, it’s actually pretty simple. A wheel bearing grease packer is a tool used to evenly distribute grease throughout the bearing. It’s a great investment for car owners who want to extend the life of their wheel bearings.

Using one is easy, too. Simply place the bearing into the packer and follow the manufacturer’s instructions for how much grease to use. Most packers will have a plunger that you push down to apply pressure and force the grease into the bearing.

Once the grease has been distributed, wipe away any excess and reassemble the bearing. Using a wheel bearing grease packer can save you time and money in the long run by helping to prevent premature bearing failure.

Description of tool and its importance

A wheel bearing grease packer is a handy tool used to make the often-messy task of applying grease to wheel bearings a breeze. This tool helps to ensure that the grease is packed firmly and evenly into the bearing, which is crucial for maintaining the performance and longevity of the wheel. When properly packed, the grease helps to reduce friction and wear, preventing damage and extending the lifespan of the bearing.

Wheel bearings are an essential component of any vehicle, and maintaining them is vital to ensure smooth and safe operation. A wheel bearing grease packer simplifies a task that can be tiresome and time-consuming, and it helps to ensure that your bearings are well-maintained, which can save you money in the long run. Whether you’re a professional mechanic or a DIY enthusiast, investing in a wheel bearing grease packer is an important step in taking care of your vehicle.

Step-by-Step Guide for Using the Tool

If you’re looking to do some maintenance on your vehicle, one important aspect you’ll want to check is your wheel bearings. To ensure your wheel bearings stay lubricated, you’ll want to use a wheel bearing grease packer. Here’s a step-by-step guide on how to use one! First, remove the inner race and outer bearing from the hub.

Then, fill the grease packer with the appropriate wheel bearing grease. Next, place the bearing into the bottom of the grease packer and slide the plunger down to force the grease through the bearing. Repeat the process with the second bearing.

Once both bearings are packed with grease, carefully reinsert them into the hub and replace the seals. With your wheel bearings properly lubricated, you can enjoy a smoother ride and extend the life of your vehicle’s parts. Remember to regularly check and re-grease your wheel bearings to keep them running smoothly.

Step One: Preparing the Wheel Bearing

When it comes to replacing wheel bearings, the first step is preparing the bearing for removal. This process involves loosening the axle nut, removing the brake caliper, and detaching the rotor from the hub. Once the rotor is off, you can access the wheel bearings.

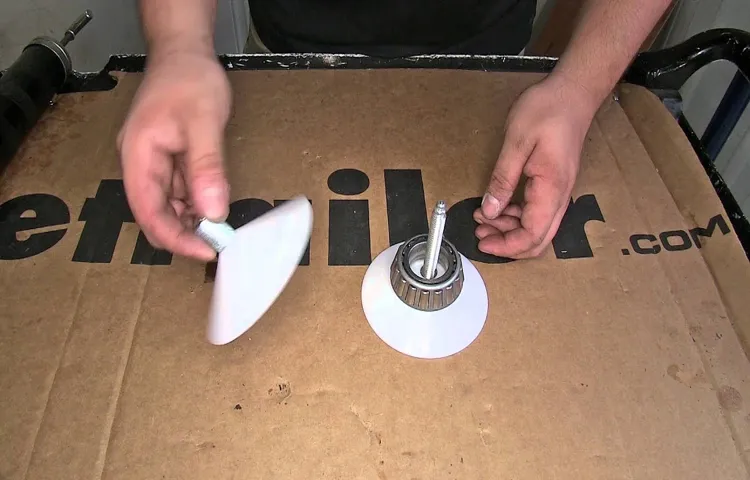

Before you can remove the bearing, you’ll need to use a tool to loosen and extract it from the hub. The tool typically consists of two parts: a handle and a press. The press fits over the bearing and applies equal pressure to the roller bearings, separating them from the hub.

Before using the tool, it’s important to clean the hub and bearing thoroughly. Use a degreaser and a brush to remove any dirt or grime that has built up on the surface. Make sure to remove any old grease or debris from the bearings themselves as well.

Once the hub and bearing are clean, it’s time to use the tool. Begin by placing the press over the bearing, making sure it’s seated properly. Then, tighten the handle to apply pressure to the bearings.

You’ll know the bearing is loose when the hub starts to move away from the press. Overall, preparing the wheel bearing for removal is a critical step in the replacement process. By cleaning the hub and bearing, and using the proper tool to extract the bearing, you can ensure a successful replacement that will keep your vehicle running smoothly.

Step Two: Preparing the Grease Packer

To properly use a grease packer, you’ll need to prep the tool before use. This step is crucial as it ensures that the grease packer is optimally filled and won’t cause any complications during use. First, ensure that the grease is a suitable consistency and can be pressed through the packer’s nozzle.

Next, unscrew the plunger from the body of the tool and scoop or pump the grease into the body until it’s full. Be sure not to overfill the grease packer as this could cause blockages and affect the tool’s performance. Once filled, reattach the plunger to the sealant packer’s body and gently pump the plunger a few times to rid the excess air in the tube.

Now, your grease packer is ready to use! With proper preparation, you can ensure that your sealant application will be quick and efficient.

Step Three: Applying the Grease to the Bearing

Applying grease to a bearing is a crucial step to ensure proper lubrication and smooth operation of the bearing. Once you have the bearing in the tool, it’s time to apply the grease. The first step is to choose the type of grease that is compatible with the bearing and the application.

Next, apply the grease slowly, taking care to distribute it evenly around the bearing. It’s important not to over-grease the bearing, as this can lead to overheating and premature failure. A good rule of thumb is to apply enough grease to cover no more than one-third of the bearing’s surface area.

Using a clean finger, spread the grease evenly around the entire surface of the bearing. Finally, wipe off any excess grease and reassemble the bearing into its housing. By following these steps, you can ensure that your bearings are properly lubricated and will operate smoothly for a long time to come.

Step Four: Checking for Proper Lubrication

Proper lubrication is crucial for smooth and safe operation of any tool, including the one you’re using. In our step-by-step guide for using the tool, we’ve reached the final check: ensuring that all moving parts are well-lubricated. First, make sure that the tool is switched off and unplugged.

Then, inspect the tool’s moving parts, such as the blades, gears, and bearings, and apply a few drops of oil or grease as instructed by the manufacturer. Be careful not to over-lubricate, as excess lubrication can attract dust and debris, leading to clogged parts and reduced performance. Once you’ve lubricated all the necessary parts, wipe away any excess oil with a clean rag.

Lastly, turn on the tool and check that all moving parts are functioning smoothly and quietly. If you hear any unusual sounds or feel any resistance, stop using the tool and re-check the lubrication. With proper lubrication, you can extend the life of your tool and ensure optimum performance.

Tips and Tricks for Using a Wheel Bearing Grease Packer

If you’re looking to replace the wheel bearings on your vehicle, using a wheel bearing grease packer can make the job much easier. Not only does it ensure that the bearings are evenly coated with grease, but it also saves you time and hassle. Here are some tips and tricks to make the most of your wheel bearing grease packer.

First, make sure that you have the correct type of grease for your vehicle. Different types of vehicles require different types of grease, so be sure to read your owner’s manual or consult with a mechanic before making any purchases. Next, clean the bearings thoroughly before placing them in the packer.

This will help ensure that the grease adheres properly and prevents any other contaminants from entering the system. Once the bearings have been loaded into the packer, pump the handle slowly and steadily until the grease begins to flow out the other side. It’s important to avoid pumping too quickly, as this can cause the grease to overflow and make a mess.

Finally, always make sure to inspect the bearings for signs of wear or damage before reassembling your vehicle. By following these simple tips, you can ensure that your wheel bearings are properly lubricated and ready to provide a smooth ride for miles to come.

Tip One: Cleanliness is Key

When it comes to using a wheel bearing grease packer, cleanliness is absolutely essential. Grease is messy stuff, and if your packer isn’t kept clean, then you’re going to end up with a lot of issues. Dirt and grime can get into the grease, causing it to become contaminated and less effective.

You might also end up with grease that’s filled with metal shavings or other types of debris, which is definitely not what you want! Make sure that you clean your wheel bearing grease packer thoroughly after every use, using a soft cloth and a mild cleaning solution. This will help to ensure that your grease stays clean and effective, and that your wheels stay well-lubricated and free from damage.

Tip Two: Don’t Overfill the Packer with Grease

One of the biggest mistakes people make when using a wheel bearing grease packer is overfilling it with grease. While it may seem like adding more grease will protect your bearings better, it can actually do more harm than good. When you overfill the packer with grease, it can cause the bearings to become too tight, which can lead to increased friction, heat, and premature wear and tear.

Not only that, but excess grease can also escape and create a mess that you’ll need to clean up. Instead, aim to fill the packer with just enough grease to cover the bearings and allow them to rotate freely. This will help keep your bearings lubricated and protected without causing any unnecessary problems.

Remember, less is often more when it comes to using a wheel bearing grease packer.

Tip Three: Keep the Tool Lubricated

When it comes to using a wheel bearing grease packer, keeping the tool lubricated is an often overlooked step that can make a big difference. Lubricating the tool before each use can ensure that it operates smoothly and efficiently. One way to lubricate the tool is to simply apply a few drops of oil to the moving parts.

Another option is to use a silicone-based lubricant, which can provide longer-lasting protection against wear and tear. Whatever lubricant you choose, be sure to apply it sparingly, as too much can actually impede the tool’s performance. With proper lubrication, your wheel bearing grease packer can remain in top condition and provide reliable service for years to come.

Conclusion and Final Thoughts

In conclusion, using a wheel bearing grease packer is like giving your car’s bearings a spa treatment. Just like how a mud mask clears out impurities from your skin, the grease packer ensures that your bearings are thoroughly coated with grease, keeping them lubricated and running smoothly. So, forget about getting your hands dirty and let the grease packer do all the work.

Trust me, your car, and your bearings, will thank you!”

FAQs

What is a wheel bearing grease packer and why is it used?

A wheel bearing grease packer is a tool used to easily and efficiently apply grease to wheel bearings. It helps to ensure proper lubrication and helps extend the life of the wheel bearings.

How do I use a wheel bearing grease packer?

To use a wheel bearing grease packer, simply place the bearing into the packer and pump the handle or lever to push the grease through the bearing. It is important to use the correct type of grease and to thoroughly clean the bearing before packing it.

What type of grease should I use with a wheel bearing grease packer?

The type of grease used with a wheel bearing grease packer can vary depending on the specific application and manufacturer’s recommendations. Generally, a high-temperature, waterproof grease is best for wheel bearings.

How often should I grease my wheel bearings?

The frequency of wheel bearing greasing can vary depending on driving conditions and manufacturer recommendations. Typically, it is recommended to grease wheel bearings at least once per year or every 12,000 miles.

Can I over-grease my wheel bearings with a grease packer?

Yes, over-greasing wheel bearings can be just as harmful as under-greasing them. It is important to follow manufacturer recommendations and only apply the recommended amount of grease.

Can I use a wheel bearing grease packer on other types of bearings?

While a wheel bearing grease packer is specifically designed for use with wheel bearings, it could potentially be used on other types of bearings. However, it is important to ensure that the packer is compatible with the specific type and size of bearing being greased.

Do I need to replace my wheel bearings after using a grease packer?

Using a wheel bearing grease packer can help extend the life of your wheel bearings. However, if your wheel bearings are worn or damaged, they may need to be replaced in addition to being properly lubricated.