Have you ever wondered how grease manages to find its way into a gimbal bearing? The answer lies in the intricate design of these essential components in any boat’s propulsion system. With multiple moving parts crammed into a small space, the gimbal bearing allows the engine to tilt and pivot with ease. However, without proper lubrication, the bearing can quickly wear down and cause significant damage to the entire system.

This is where grease comes in, acting as a protective barrier against friction and heat. But how does it get there? Let’s take a closer look.

Table of Contents

Introduction

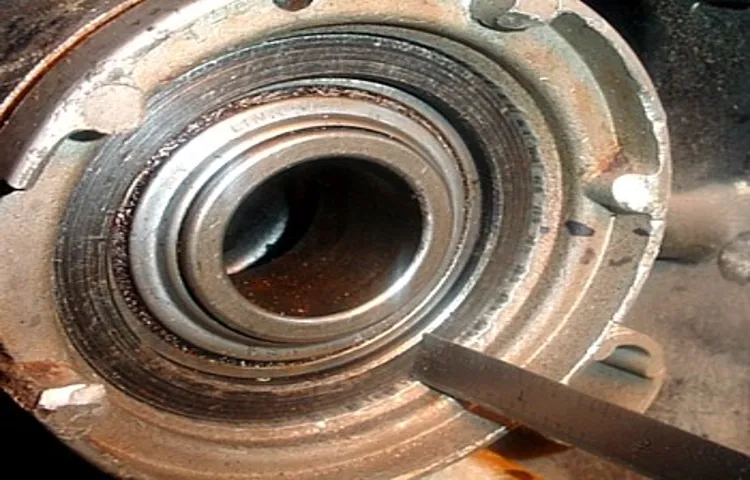

Grease getting into a gimbal bearing is a common problem faced by many boat owners. So, how does it happen? Well, the gimbal bearing is responsible for transferring power from the engine to the stern drive unit, which helps to turn the propeller. Over time, the bearing can become worn out, which causes small cracks and gaps to form in the protective seal.

These gaps allow water and debris to enter, causing corrosion and damage to the bearing. When the seal breaks down, grease can also leak out and mix with the water, creating a milky white substance that’s easy to spot. It’s important to fix this issue as soon as possible, as a damaged gimbal bearing can cause serious damage to your boat’s engine.

Definition of Gimbal Bearing

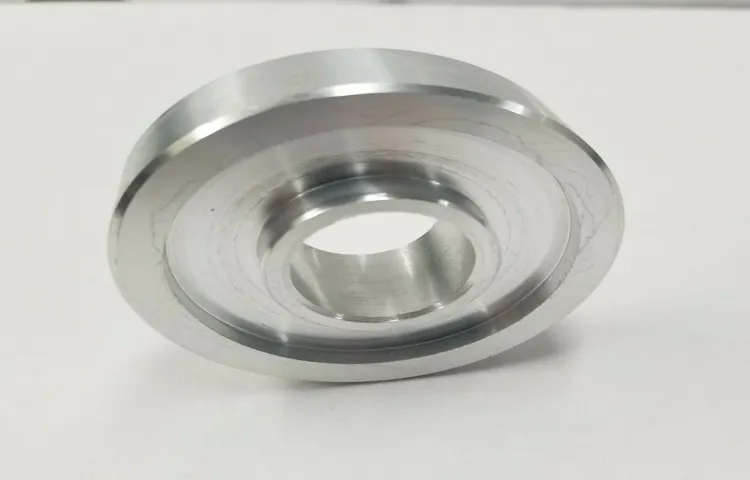

A gimbal bearing is a crucial component of a boat’s engine system, as it enables the drivetrain to rotate smoothly. It is a small, cylindrical-shaped metal bearing that connects the engine’s crankshaft to the propeller shaft and allows the propeller shaft to rotate independently of the engine’s movement. This is essential for the transfer of power from the engine to the propeller, enabling the boat to move forward.

Without a proper gimbal bearing, the engine’s movement would cause excessive wear and tear on the propeller shaft, leading to damage and ultimately, failure. Therefore, maintaining and replacing the gimbal bearing periodically is essential to ensure the smooth operation and longevity of a boat’s engine system.

Why Grease is Necessary in Gimbal Bearings

Gimbal bearings are a crucial component in most marine and boat engines, allowing steering and directional control while out on the water. However, these bearings can experience significant wear and tear over time, leading to friction and loss of function. That’s where grease comes in.

Grease is a lubricant that can help reduce friction between the bearing surfaces. By applying grease to the gimbal bearings, you can prolong their lifespan and reduce the chances of mechanical failure. Without grease, the bearings would rub together and eventually lead to catastrophic failure, potentially causing damage to the boat or even putting lives in danger.

Therefore, it’s essential to use grease regularly to ensure the proper functioning of gimbal bearings.

Factors that Lead to Grease Contamination

Grease contamination in gimbal bearings is a common issue that can lead to bearing failure. There are several factors that contribute to grease contamination in a gimbal bearing. One common cause is the lower quality of grease used in the bearing, which can break down and wash out quickly, leaving the bearing unprotected.

Another factor is the lack of proper maintenance and servicing, which can cause the grease to become contaminated with dirt, water, or other contaminants. Additionally, over-greasing the bearing can cause excess grease to enter the housing and ultimately contaminate the bearing. It is crucial to regularly inspect and maintain the gimbal bearing to ensure that it is correctly lubricated and free from contamination, as this can significantly extend the life of the bearing.

Furthermore, choosing the right grease and applying it correctly can help prevent unnecessary damage and failure of the gimbal bearing.

Water Intrusion

Water intrusion can be a major problem in any establishment, but it is particularly concerning when it comes to kitchens and restaurants. When water enters the kitchen, it can carry with it a number of contaminants, including grease. There are several factors that can lead to grease contamination in these settings.

For one, if there are any leaks in the plumbing or drainage system, wastewater can mix with kitchen grease and result in higher levels of contamination. Additionally, improper cleaning practices can also contribute to grease buildup. This can happen when employees fail to clean appliances or surfaces thoroughly, leaving behind layers of grease.

To prevent water intrusion and resulting grease contamination, it’s important to conduct regular inspections and maintenance in the kitchen, including checking for leaks and ensuring that all surfaces are cleaned thoroughly and regularly.

Oil Leaks

Oil Leaks Oil leaks can be a headache for any machinery owner. One of the factors that lead to grease contamination is water. Contaminated grease can cause damage to bearings, gears, and other engine components.

To avoid this from happening, it’s important to regularly inspect and replace seals, as they are the first line of defense against contaminants. Another factor that can lead to grease contamination is improper storage. It’s important to store grease in a clean, dry environment to avoid moisture and dirt from entering.

Lastly, using the wrong grease can lead to contamination. Make sure to use the correct type of grease recommended by the machinery manufacturer. This ensures maximum performance and helps prevent any accidents or breakdowns.

By being mindful of these factors, you can prevent oil leaks and avoid costly repairs.

Poor Quality Grease

Grease contamination can occur due to various factors, but poor-quality grease is one of the key culprits. Low-quality grease can arise from various reasons, like inadequate quality control measures, suboptimal manufacturing processes, and the use of cheap raw materials. These factors can lead to lubricants having inferior properties, such as poor viscosity index, low flashpoint, and limited thermal stability.

When such grease is used in machinery, it can cause severe wear and tear, corrosion, and increased friction levels, leading to premature equipment failure. To address grease contamination due to poor-quality lubricants, it’s essential to select grease from reputable manufacturers and use the correct type of grease for the equipment based on the manufacturer’s recommendations. It’s also advisable to conduct regular tests and inspections to monitor the lubricant’s performance and replace it when necessary.

By taking these steps, you can prevent grease contamination, improve equipment reliability, and extend the machinery’s lifespan.

Effects of Grease Contamination in Gimbal Bearings

Grease contamination in gimbal bearings can have a significant impact on their performance and longevity. But how does the grease get into the bearing in the first place? In many cases, improper maintenance or over-greasing can result in excess grease being forced into the bearing. This can cause the grease to break down, form deposits, and ultimately lead to bearing failure.

In other cases, contaminants such as dirt, debris, or even water can mix with the grease and enter the bearing, leading to similar issues. Once the grease is contaminated, it can begin to cause damage, leading to increased friction and wear, poor handling, and even total failure of the gimbal. If you want to avoid these issues, it’s important to follow proper maintenance procedures and use the right type and amount of grease for your bearings.

This will help to keep your gimbal performing smoothly and reliably over the long term.

Increased Friction

Gimbal bearings are essential for the proper functioning of various machinery, from boats to drones. However, when grease contamination occurs in these bearings, it can cause significant issues. One of the most notable effects is increased friction between the bearings and their respective components.

This increased friction can lead to excessive strain on the bearings, causing them to wear out more quickly. Moreover, the added resistance can make it challenging for the machinery to operate efficiently, reducing overall performance and potentially causing damage. It’s crucial to address grease contamination in gimbal bearings promptly to avoid these adverse effects.

Regular cleaning and maintenance can prevent excess grease buildup and ensure that the bearings continue to function optimally.

Reduction in Bearing Efficiency

When it comes to gimbal bearings, any kind of contamination can have a detrimental effect on their efficiency, especially grease contamination. If not managed properly, the grease can change its properties and cause the bearings to become sluggish and reduce their performance. Over time, the bearings can wear out faster, leading to costly repairs.

To avoid this, proper maintenance is necessary, including regular cleaning and using high-quality grease. It’s like taking care of a car – if you don’t change the oil regularly, the engine won’t run smoothly, and you’ll end up needing more repairs. The same goes for gimbal bearings – take care of them, and they’ll take care of you.

Corrosion and Degradation

Gimbal bearings are vital components that allow for the rotation of a shaft, making them essential in many different types of machinery. However, these bearings are vulnerable to degradation and corrosion, which can lead to costly repairs and even equipment failure. One major cause of this degradation is grease contamination.

When grease gets into these bearings, it can create a corrosive environment that can quickly cause significant damage, leading to failure and potentially catastrophic consequences. This is because the presence of grease can lead to an increase in water content, which can cause rust and corrosion in the bearings. Therefore, it’s essential to be vigilant and keep the bearings clean and well-maintained to avoid these problems.

By doing so, you can ensure the longevity and safety of your equipment, avoiding significant downtime and costly repairs.

Preventing Grease Contamination in Gimbal Bearings

One of the common issues with gimbal bearings is grease contamination, which can lead to premature wear and failure. But how does the grease get into a gimbal bearing in the first place? Well, there are a few ways. First, it can come from over-zealous greasing of adjacent fittings, which can result in excess grease flowing into the gimbal bearing.

Second, it can enter through a damaged or worn seal, allowing contaminants to infiltrate the bearing. Regular maintenance checks to ensure seals are intact can help prevent this. Third, grease contamination can occur during the bearing’s production process if it is not cleaned thoroughly before assembly.

Regular inspection and cleaning of gimbal bearings can help prevent grease contamination, prolonging their lifespan and preventing costly repairs.

Regular Maintenance

Regular maintenance is crucial for keeping your gimbal bearings functioning properly and preventing grease contamination. Gimbal bearings are essential components in stabilizing camera movements, and they require proper maintenance to prevent deteriorating performance. The buildup of grease in the bearings can cause spinning issues, vibrations, and overall poor functionality.

Avoiding dust, sand, and other debris from getting into your bearings can help prevent contamination. Additionally, regularly cleaning and lubricating your gimbal can help prevent any potential problems from arising. Consider using a lint-free cloth to clean your bearings and use lubricants specifically designed for your gimbal to ensure optimal performance.

Maintaining your bearings will help ensure that your camera movements remain smooth and free of unwanted vibrations, allowing you to capture outstanding footage.

Proper Use of Grease

The proper use of grease is crucial when it comes to maintaining gimbal bearings and preventing contamination. Without the right amount and type of grease, the bearings can wear down quickly, causing damage to your equipment and compromising your shots. But it’s not just about applying grease; it’s also about making sure the grease is clean and free from contaminants.

One effective way to prevent contamination is by using a grease gun with a clean nozzle when applying grease. This minimizes the risk of introducing dirt or debris into the bearings, which can cause friction, heat, and premature failure. It’s also important to keep the grease container and the area around it clean, and to avoid using old or expired grease.

By taking these simple steps, you can ensure that your gimbal bearings stay in top condition and perform at their best when you need them most.

Effective Sealing Techniques

Gimbal bearings are vital components of marine vessels, and keeping them in excellent working condition is crucial for smooth sailing. One of the most common problems encountered with gimbal bearings is grease contamination, which can lead to premature wear, poor performance, and damage to other vital components. However, effective sealing techniques can help prevent this issue from occurring.

By utilizing durable seals that can withstand harsh marine environments and regular maintenance, grease contamination can be minimized, and gimbal bearings can remain in excellent working condition. It is essential for vessel owners to work closely with experienced technicians who can recommend the best sealing techniques and ensure that regular maintenance is performed to keep gimbal bearings in optimal condition. By doing so, vessel owners can reduce downtime, save on costly repairs, and enjoy uninterrupted pleasure or commercial cruising on their vessel.

Conclusion

In conclusion, the mysterious journey of how grease manages to infiltrate the inner workings of a gimbal bearing is both complex and fascinating. Like a ninja, the grease silently weasels its way through the tiniest openings, sliding past seals and barriers, until it finally reaches its intended destination. It’s almost as if the grease has a secret mission, determined to keep the bearing lubricated and running smoothly.

So, if you ever find yourself wondering how grease gets into a gimbal bearing, just remember – it’s all part of a sly and strategic plan.”

FAQs

What is a gimbal bearing and where is it located in a boat?

A gimbal bearing is a support component located in the stern of an inboard boat engine that helps the drive shaft to rotate smoothly and transfer power from the engine to the boat’s drive system.

How does grease get into a gimbal bearing?

Grease can be injected into the gimbal bearing using a grease gun. The old grease must be removed first using a degreaser, and then the new grease is forced into the bearing until it is filled completely.

What are the signs of a bad gimbal bearing?

Signs of a bad gimbal bearing include a clunking noise when shifting gears, vibration at slow speeds, and difficulty in steering or maneuvering the boat.

Can a bad gimbal bearing cause damage to other parts of the boat?

Yes, a bad gimbal bearing can cause damage to the drive system, including the U-joints, couplers, and output shafts if not repaired promptly.

What is the lifespan of a gimbal bearing?

The lifespan of a gimbal bearing depends on the frequency of use, conditions of use and maintenance. With proper care, the gimbal bearing can last for several years.

How often should I have my gimbal bearing checked?

It is recommended to have your gimbal bearing checked by a professional during annual maintenance or after every 200 hours of use to ensure it is in good condition.

Can I replace a gimbal bearing myself?

While it is possible to replace a gimbal bearing yourself, it is recommended to have it done by a professional mechanic with experience in handling boat engines to prevent damage to other parts of the boat.