When it comes to maintaining the performance and longevity of your trailer’s bearings, it’s crucial to ensure they are well-lubricated. One popular method of greasing trailer bearings is by using Bearing Buddy, a device designed to apply and maintain a consistent amount of grease in a trailer hub. However, a common question that often arises is: how much grease should you actually put in a Bearing Buddy? Over-greasing or under-greasing can both lead to problems, ranging from bearing damage to loss of lubrication.

In this blog, we’ll explore how to determine the right amount of grease to put in a Bearing Buddy, ensuring optimal performance and protection for your trailer. So, let’s dive in!

Table of Contents

Introduction

If you want your boat trailer wheel bearings to function smoothly, it is essential to grease them regularly. One popular option for lubrication is the use of Bearing Buddies. However, the question many boat owners ask is how much grease should they put in Bearing Buddies? The answer is straightforward.

You only need to pack the hub until the grease pushes out the rear seal. It’s because you don’t want to over-grease and create too much pressure, which can cause damage as well. It’s best to perform this task after every use of the boat and trailer, preventing any potential problems.

Remember, regular greasing is crucial in protecting your bearings from friction and heat that can cause wear and tear, ultimately extending the lifespan of your equipment.

What is Bearing Buddy?

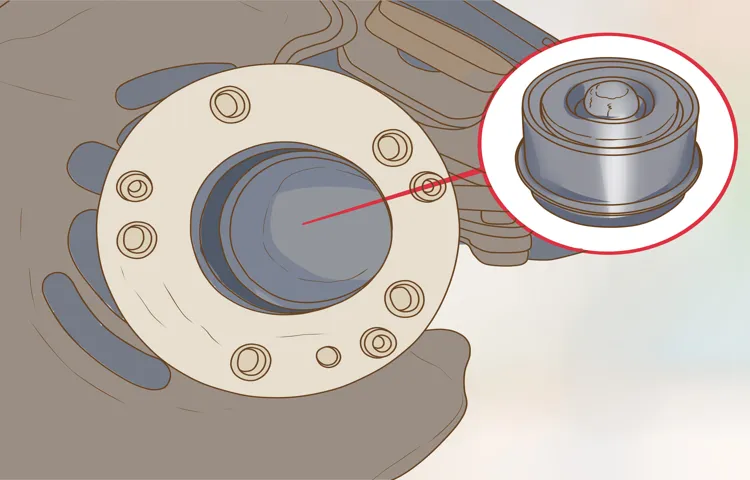

Bearing Buddy is an essential tool for those who own trailers or boats that require wheel bearing maintenance. It’s a device that maintains and controls the amount of grease inside the wheel bearings to protect them from water, debris, and dust. This mechanism has been designed to make the bearing lubrication process easier, safer, and more precise, reducing the risk of bearing failure.

Bearing Buddy works by creating a positive pressure seal, keeping the water and debris out while forcing grease into the bearing chamber continually. By using Bearing Buddy, you can extend the life of your trailer and boat’s wheel bearings, ensuring a smooth and safe ride for you and your cargo. If you’re looking for a cost-effective way to maintain your trailer’s bearings and safeguard your boating experience, Bearing Buddy is your answer.

Why is Grease Important for Bearing Buddy?

Grease is an essential component necessary to keep Bearing Buddy in good working condition. Bearing Buddy is a device that is used to provide constant protection and lubrication to wheel bearings that are found on boat trailers. The grease that is used in Bearing Buddy is designed to protect the wheel bearings from any dirt, water, or other debris that may cause damage to the wheel bearings.

It also provides protection against rust and corrosion, which can get into the bearings and cause damage. The proper application of grease can extend the life of the bearings and protect them from damage, ensuring smooth and easy operation of your trailer. Therefore, good quality grease is important when it comes to keeping Bearing Buddy functioning optimally.

Determining the Right Amount of Grease

If you’re wondering how much grease to put in your bearing buddy, there are a few things to consider. First of all, it’s important to note that over-greasing can actually be just as bad for your bearings as under-greasing. So, how do you determine the right amount? One way is to fill your bearing buddy about 3/4 full with grease.

This ensures that there is enough grease to lubricate the bearings, but not so much that it will cause unnecessary pressure. Another option is to use a grease gun with a pressure gauge, which can help you accurately measure the amount of grease being applied. Remember to always check your bearing buddy periodically to ensure that it is still properly packed with grease, and to avoid any potential damage to your bearings.

So, whether you’re taking your boat out on the water or hitting the road with your trailer, make sure to take the time to properly grease your bearings for a smoother, more efficient ride.

Manufacturer Recommendations

When it comes to keeping your machinery in good working order, one of the most important tasks is ensuring that you’re using the right amount of grease. Many manufacturers will provide recommendations for the amount of grease needed to maintain their products, so it’s important to pay attention to these guidelines. Following these recommendations can help prevent issues like premature wear, excess heat, and bearing failure.

One of the key factors to keep in mind when determining the right amount of grease is the operating conditions of your machinery. If your equipment is exposed to high temperatures, loads, or speeds, you may need to use more frequent or heavier applications of grease. On the other hand, if your machinery operates in a milder environment, you may be able to use a lighter or less frequent amount of grease.

Regardless of your specific situation, it’s important to carefully read and follow all of the manufacturer’s recommendations for greasing your equipment. Doing so can help ensure that your machinery operates smoothly and efficiently for years to come.

Using a Grease Gun

When it comes to using a grease gun, determining the right amount of grease to use is crucial. Too little grease may not provide enough lubrication, while too much grease can cause seal damage and lead to excessive heat buildup. To determine the appropriate amount of grease, you should consult the manufacturer’s recommendations and fill the grease gun accordingly.

It’s also important to monitor the amount of grease being dispensed during application and adjust accordingly to avoid over-lubrication. Like pouring syrup on pancakes, you want just the right amount to achieve a smooth and satisfying result. So, take your time and make sure to strike the perfect balance for optimal performance and longevity.

Visual Inspection Method

When it comes to determining the right amount of grease for your machinery, the visual inspection method can be incredibly useful. This involves checking the lubricated area for any signs of excess or insufficient grease. It’s important to note that adding too much grease can actually be detrimental to your machinery by increasing friction and generating heat.

On the other hand, not enough grease can cause wear and tear on crucial components. When inspecting for the right amount of grease, look for visible signs such as excessive grease buildup around fittings or leaking seals. Utilize the dipstick method to check for the appropriate level of grease in the reservoir.

Remember, finding the right balance can extend the life of your machinery and save you money in the long run.

Using a Scale

When it comes to applying grease to your machinery, it’s important to use the right amount. Too little and you risk causing friction and wear, too much and you risk attracting dust and debris that can clog the gears. That’s where using a scale comes in handy.

By weighing your parts before and after greasing, you can determine the ideal amount of grease to apply. This not only ensures optimal performance but also extends the life of your equipment. Using a scale is a simple and effective way to get the job done right every time.

So, the next time you’re greasing your machinery, don’t leave it up to guesswork, grab a scale and get accurate measurements for optimal performance.

Conclusion

In conclusion, the age-old question of how much grease to put in a bearing buddy is one that may never have a straightforward answer. Some say less is more, while others advocate for a “grease it up” approach. Ultimately, the amount of grease needed depends on the individual situation and the condition of the bearings.

So, it’s important to trust your gut, use your own judgment, and remember that a properly greased bearing buddy is key to keeping your equipment running smoothly. As the saying goes, “a little grease goes a long way, but too much grease can make a mess.” So, find that sweet spot and keep those bearings spinning like a well-oiled machine.

“

Importance of Proper Greasing

Proper greasing is a critical aspect that ensures the longevity and excellent performance of your equipment. It is, therefore, essential to determine the right amount of grease to apply to avoid over-lubricating or under-lubricating. Applying too much grease can result in equipment failure, while using too little can lead to friction, heat buildup, and rapid wear and tear.

Determining the right amount of grease requires utilizing the manufacturer’s recommendations on the type, frequency, and quantity of grease to apply. This will help to ensure that the equipment operates smoothly, efficiently, and for an extended period. In conclusion, proper greasing is essential for optimal equipment performance, but it’s equally necessary to determine the right amount of grease to apply to prevent any damage.

Summary of Tips

Determining the right amount of grease for your machinery is crucial to ensure optimal performance and prevent potential damage. One key tip is to consult the manufacturer’s recommendations for the specific type of machine and the corresponding grease type and quantity. Another factor to consider is the operating conditions such as temperature, load, and speed.

In general, it is better to err on the side of caution and apply slightly less grease rather than over-lubricating, which can cause excess heat, material build-up, and contamination. A useful analogy is to think of greasing a machine like applying sunscreen to your skin: you want to apply enough to provide protection, but not so much that it becomes greasy and attracts dirt and debris. By following these tips and regularly monitoring and adjusting the grease levels as needed, you can prolong the lifespan of your equipment and avoid costly repairs.

FAQs

What is a bearing buddy?

A bearing buddy is a device used for lubricating boat trailer wheel bearings.

How does a bearing buddy work?

A bearing buddy works by filling the hub with grease and maintaining the pressure inside the hub to prevent water from entering the bearings.

Can I use any type of grease in a bearing buddy?

No, it is recommended to use a marine grade grease specifically designed for boat trailer wheel bearings.

How much grease should I put in a bearing buddy?

A general rule of thumb is to fill it up to 1/3 to 1/2 full.

How often should I grease my bearings with a bearing buddy?

It is recommended to grease your bearings before and after each boating season, or every 3,000 miles.

Can I overfill my bearing buddy with grease?

Yes, overfilling the bearing buddy can cause damage to the seals and lead to grease leaking out of the hub.

Can I replace my bearing buddy myself?

Yes, replacing a bearing buddy is a fairly simple task and can be done with basic hand tools. However, it is recommended to consult with a professional if you are not comfortable with the process.