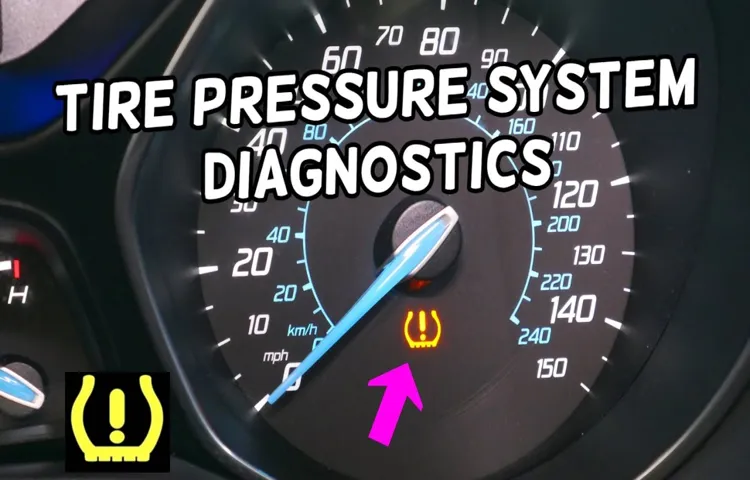

Imagine you’re driving down the highway, and suddenly, the tire pressure light illuminates on your dashboard. Your immediate reaction might be to assume that one of your tires is low on air, but what if it’s a bad tire pressure sensor instead? Knowing how to determine a bad tire pressure sensor is essential for any driver, as a faulty sensor can lead to inaccurate readings and potential safety hazards on the road. In this guide, we’ll explore the signs of a bad tire pressure sensor, how to diagnose the issue, and steps you can take to fix the problem.

So, buckle up and let’s dive in!

Table of Contents

Introduction

If you own a car with a tire pressure monitoring system, you may find it challenging to determine which tire pressure sensor is not functioning correctly. The tire pressure sensor sends vital information to your car’s computer, and if it fails, it can be dangerous and cause significant damage to your vehicle. Some common indicators of a malfunctioning tire pressure sensor include alerts on your dashboard, inappropriate readings, and warning lights.

It’s essential to understand that a tire pressure sensor’s lifespan is around five to ten years, depending on how you maintain it. To identify which tire pressure sensor is defective, you can use a tool specifically designed to read the tire pressure sensor data. It is advisable to take your car to a professional mechanic when you suspect there is an issue with your tire pressure sensor, as they have the necessary knowledge and tools to assess the state of your vehicle and provide you with accurate advice on how to fix the problem.

– Explanation of tire pressure sensors

Tire pressure sensors are an essential component of modern-day vehicles that provide real-time data on tire pressure levels. These sensors work by monitoring the air pressure inside the tires and transmitting the information to a central module for processing. The module then sends an alert to the driver if the pressure drops below a certain threshold.

This helps to prevent accidents and improve fuel efficiency, as underinflated tires lead to increased rolling resistance and greater fuel consumption. It’s important to note that tire pressure sensors vary in their accuracy and precision, with some being more reliable than others. Therefore, it’s important to choose a reputable brand that provides high-quality sensors for your vehicle.

By regularly monitoring tire pressure levels, you can ensure that your tires are operating optimally and minimize the risk of a blowout or other tire-related issues.

– Importance of identifying a bad sensor

Identifying a bad sensor is crucial in various industries where sensors are widely used. A sensor is a device that detects and responds to a particular input from the physical environment, such as temperature, pressure, or light, among others. When a sensor is malfunctioning or not working correctly, it may cause false readings, leading to inaccurate measurements, which can be disastrous in critical environments like the automotive or health industries.

Therefore, it’s essential to identify a bad sensor early enough to prevent significant problems. Regular testing and calibration of sensors are crucial to detect any possible errors and ensure their proper functioning. By identifying a bad sensor, a replacement can be done early enough to avoid the risk of incorrect measurements and subsequent losses.

Method 1: Using a TPMS Tool

If you want to determine which tire pressure sensor is causing problems in your vehicle, using a TPMS tool is an effective method. This tool is specifically designed to read the data transmitted by each sensor and show you the readings in real-time. To use the tool, you will need to connect it to your vehicle’s OBD-II port and follow the instructions provided in the manual.

Once connected, the tool will display the tire pressure readings from each sensor in real-time. If you notice a sensor that is displaying a consistently lower or higher pressure than the other sensors, this is an indication that the sensor has a problem. You may need to replace this sensor to ensure that your vehicle’s tire pressure monitoring system is working correctly.

Using a TPMS tool can save you time and money in identifying which sensor needs attention, making it a popular method among vehicle owners.

– Explanation of TPMS tool

TPMS tool A TPMS tool is an essential device that helps drivers keep track of their tire pressure and temperature for maximum safety and performance. Using a TPMS tool is relatively easy and involves the use of sensors that are mounted on each tire. The tool then retrieves and displays the sensor readings, enabling the driver to identify any potential issues with their tires.

The process involves a quick and simple set-up, with most TPMS tools equipped with user-friendly interfaces and automated functions. One of the most significant advantages of using a TPMS tool is that it provides real-time reliable data, making it easier to identify the exact location and nature of any problems. By regularly using a TPMS tool, drivers can prolong the lifespan of their tires, improve fuel efficiency, and reduce their risk of accidents related to tire failure.

Overall, a TPMS tool should be a vital part of every driver’s toolkit, ensuring their safety and that of their vehicle’s.

– Steps for using TPMS tool to determine bad sensor

If you’re looking to determine a bad sensor in your vehicle’s TPMS (Tire Pressure Monitoring System), using a TPMS tool is a great method to start with. First, make sure your vehicle is switched off, then plug in your TPMS tool into the OBD-II port, usually located under the dashboard. Turn the TPM tool on and select the make and model of your vehicle along with the year of manufacture.

The tool will then begin scanning your vehicle’s TPMS system, detecting any malfunctions or faulty sensors. Some advanced tools may even display the specific sensor that is causing the issue, along with its battery life and other diagnostic details. Once the scan is complete, you can reset the system or replace the problematic sensor accordingly.

Using a TPMS tool simplifies the process of identifying and resolving TPMS issues, making it an essential tool for every mechanic or anyone who works on car maintenance.

– Example of TPMS tool output

A TPMS (Tire Pressure Monitoring System) tool is a device used to measure and display the air pressure and temperature of a vehicle’s tires. Typically, a TPMS tool will display information such as the tire pressure in PSI, the temperature of the tire, and the status of the TPMS sensors on each tire. This information is crucial in ensuring that each tire is properly inflated and functioning as intended.

It’s a quick and easy way to check your vehicle’s tires and make sure they are safe for the road. Using a TPMS tool can help prevent tire damage, improve fuel efficiency, and increase the lifespan of your tires. Overall, investing in a TPMS tool can save you time, money, and more importantly, ensure your safety while on the road.

Method 2: Observation and Testing

If you suspect that one of your tire pressure sensors is bad, one method you can use to determine which one it is involves observation and testing. Start by checking the tire pressure readings on your vehicle’s dashboard and comparing them to the recommended pressure levels in your owner’s manual. If one tire consistently shows a significantly different reading, it could be an indication that the sensor for that tire is not functioning properly.

Next, you can try swapping the suspected sensor with one from another tire and see if the readings change. If the readings still show a problem with the originally suspected tire, it’s likely that the sensor for that tire is indeed bad. It’s important to note that this method may not always be foolproof, and in some cases, it may be necessary to take your vehicle to a professional for a more accurate diagnosis.

However, by using a combination of observation and testing, you may be able to pinpoint which tire pressure sensor is causing issues and get it fixed before it leads to bigger problems.

– Signs of a bad sensor to observe

When it comes to identifying a bad sensor, observation and testing are excellent methods to detect potential problems. One sign of a malfunctioning sensor may include a check engine light that remains on even after vehicle maintenance or repairs. Additionally, if a sensor is faulty, the driver may notice a drop in fuel efficiency or a decrease in vehicle performance.

Taking note of any unusual sounds, such as knocking or clicking, or smells, such as burning odors, may also be signs of a bad sensor that requires immediate attention. Regular vehicle maintenance and inspection can help identify any issues with sensors before they become severe. By keeping an eye out for these signs, drivers can prevent larger and more costly issues from occurring down the road.

– Testing process for the sensors

When it comes to testing the sensors, there are a number of methods that can be used. One effective approach is simply observing and testing the sensors in question. This involves paying close attention to the performance of the sensors over time, running controlled tests to see how they behave under different conditions, and documenting any issues or inconsistencies that arise.

By doing this, it is possible to identify any patterns or trends that may be affecting the accuracy or reliability of the sensors, and to take appropriate steps to address them. This method can be particularly useful when dealing with complex sensor systems that require careful calibration and monitoring in order to function optimally. By staying alert and focused, and by applying basic scientific principles and methods, it is possible to ensure that the sensors are functioning exactly as they should be, and that they are providing accurate and reliable data.

– Example of testing process output

Observation and testing are crucial components of the testing process. If done correctly, they can help identify defects early on, leading to faster and more effective bug fixes. This method involves carefully observing how the software operates in different scenarios, and rigorously testing it for any potential issues that arise.

This approach is essential in ensuring that the software is not only functional but also meets all of the user’s requirements. When observing and testing, it is important to keep in mind that the software might behave differently under different conditions, so it is essential to test it under as many different scenarios as possible. By doing this, testers can identify and isolate any issues that may arise, ensuring that the software functions as expected.

Over time, this method can help improve the overall quality of the software and reduce the number of bugs that are found in the future.

Conclusion

Determining which tire pressure sensor is bad can be like searching for a needle in a haystack, but fear not! With some basic tools and a bit of know-how, you can quickly identify the culprit and put your mind at ease. Remember to always be vigilant and keep your tires properly inflated to avoid any blowouts or unexpected roadside mishaps. So, don’t let a faulty sensor deflate your confidence on the road, take charge and get back to cruising with ease!”

– Importance of proper tire pressure sensor maintenance

Maintaining proper tire pressure is extremely important for ensuring your safety on the road, as well as the health of your vehicle. And to do that, you need to properly maintain its tire pressure sensor. One easy way to check if your sensor is functioning properly is through observation and testing.

First, visually inspect the tires for any signs of low pressure or damage. Then, use a tire pressure gauge to check the pressure in each tire. Compare the reading to the recommended pressure listed in your vehicle’s owner manual.

If the readings are off, there may be an issue with the sensor. Next, try resetting the sensor by following the instructions in your owner’s manual. If that doesn’t work, it may be time to take your vehicle to a mechanic for repairs or a replacement.

Remember, regularly checking and maintaining your tire pressure sensor can keep you safe and save you money in the long run.

– Reminder to consult a professional if unsure

When it comes to inspecting the condition of your home, there’s nothing better than using your eyes and a few basic tests. Simple tools like a flashlight, screwdriver, and ladder can help you assess the overall condition of your home’s exterior and interior. But it’s important to remember that if you’re unsure about anything during the inspection, you should consult a professional.

Observation and testing can provide you with invaluable insights about the state of your home, but it’s not a substitute for professional expertise. While you’re conducting your inspection, keep an eye out for things like cracks in the walls, water damage, faulty electrical outlets, and uneven flooring. These could all be signs of bigger issues and may require professional attention.

Remember, your observations and tests are just the first step in understanding the overall condition of your home. Always consult with an expert if you have any doubts or concerns.

FAQs

1. How do I know if my tire pressure sensor is malfunctioning?

You can check your tire pressure reading on the dashboard. If all tires have the same reading and it is incorrect, then it’s likely that your tire pressure sensor is malfunctioning.

2. What should I do if my tire pressure sensor is not working correctly?

You should take your vehicle to a certified mechanic to have the tire pressure sensor diagnosed and repaired.

3. Can I drive with a faulty tire pressure sensor?

Yes, but it’s not recommended. Without a functioning tire pressure sensor, you won’t know if your tires are underinflated, which can lead to poor handling, increased risk of tire blowout, and decreased fuel efficiency.

4. Is it costly to replace a tire pressure sensor?

The cost of replacing a tire pressure sensor varies depending on the make and model of your vehicle. Typically, the cost can range from $50 to $250 per sensor.

5. How frequently do tire pressure sensors need to be replaced?

There is no set lifespan for tire pressure sensors, but they can last up to 10 years or more. However, it’s essential to have them checked regularly during routine maintenance.

6. Can I recalibrate my tire pressure sensor without visiting a mechanic?

Some newer vehicles have a calibration function in the dashboard system, which allows the driver to reset the tire pressure sensors without needing a mechanic.

7. How does a tire pressure sensor work?

A tire pressure sensor is located inside the tire, typically in the valve stem. It works by sending a signal to the vehicle’s onboard computer, which collects data on tire pressure and displays the readings on the dashboard.