Picture this: you’re on a long road trip to the beach with a trailer hauling all of your gear. Suddenly, you hear a noise coming from the trailer, and upon inspection, you notice that the trailer bearings need greasing. Not sure how to grease trailer bearings? No worries, we’ve got you covered! In this step-by-step guide, we’ll walk you through everything you need to know about greasing trailer bearings, from the tools you’ll need to how often you should be doing it.

So grab your grease gun and let’s get started!

Table of Contents

Gather Required Materials

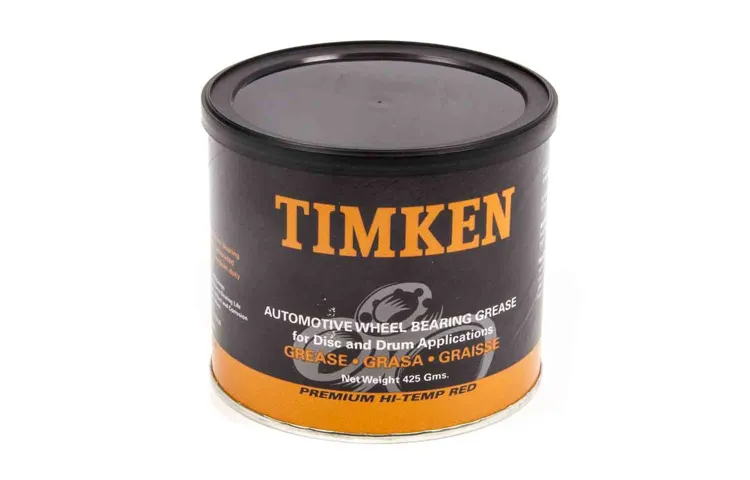

If you own a trailer, it’s important to keep the bearings adequately lubricated, which keeps the wheels turning smoothly and can help ensure your vehicle stays on the road. Before you get started, you’ll first need to gather a few key materials. Firstly, make sure you have the right type of grease for your trailer – this can vary depending on the size and weight of the vehicle.

Next, you’ll need a bearing packer tool, which will make the process much easier and faster. You’ll also need a jack to lift the trailer up so you can access the bearings, and jack stands to keep it at a safe height. Finally, make sure you have a clean rag and some disposable gloves to keep your hands clean and protect your skin from the grease.

By having all these materials ready before you start, you’ll be able to grease your trailer bearings safely and effectively, without having to interrupt your workflow to go out and buy additional supplies.

– Wheel chocks – Jack stands – Wheel bearing grease – Rubber gloves – Clean rag – Paper towels – Grease gun – Cotter pin

Before you start working on your car, it’s important to gather all the necessary materials so that you can work efficiently and safely. Firstly, wheel chocks are an absolute must to prevent your vehicle from moving during repairs. Secondly, jack stands are essential for supporting your car while you work underneath it.

You should also have a good quality wheel bearing grease to lubricate the bearings during maintenance. Rubber gloves are vital to protect your hands from any fuel, oils, grease, or other chemicals that may be harmful. Don’t forget to bring a clean rag and paper towels for wiping away any grease or grime.

You’ll also need a grease gun to properly lubricate your vehicle. Lastly, cotter pins are small but essential pieces to secure nuts and bolts, so it’s important not to overlook them. Having all of these materials ready before getting started will ensure your repairs go smoothly and safely.

Remove Wheel and Hub

When it comes to maintaining your trailer, greasing the bearings is critical to ensuring a smooth and safe ride. The first step to greasing trailer bearings is to remove the wheel and hub. This can be done by raising your trailer with a jack and placing it on jack stands.

Next, use a socket wrench to remove the lug nuts that hold the wheel in place. Once the wheel is removed, you can see the hub and spindle. Remove the dust cap with pliers and use a pair of channel locks to remove the cotter pin at the end of the spindle.

Now you can slide the hub off the spindle, exposing the bearings and races. Inspect them thoroughly for wear and damage before cleaning them with solvent and a clean rag. Once the bearings and races are cleaned and inspected, you can apply fresh grease to the bearings before reattaching the hub and wheel.

By greasing your trailer bearings regularly, you can ensure that your trailer runs smoothly and avoids costly repairs down the road.

– Securely block the vehicle and loosen the lugnuts – Use a jack to lift and support the trailer – Remove the lugnuts and take off the wheel and hub assembly

When it comes to removing the wheel and hub assembly from your trailer, there are several steps you need to follow to ensure the process is carried out safely and effectively. First, it’s crucial to securely block the vehicle and then loosen the lugnuts before using a jack to lift and support the trailer. Once you’ve done this, you can proceed to remove the lugnuts and take off the wheel and hub assembly.

It’s important to take care when removing the assembly, as it can be heavy and difficult to maneuver. You might need to use a pry bar to gently separate the assembly from the axle. Once you’ve successfully removed the wheel and hub assembly, you should inspect the brake components and bearings for any signs of wear or damage.

If you notice any issues, it’s best to replace these parts before putting the wheel and hub assembly back onto the trailer. By following these steps and taking the time to carefully inspect your trailer components, you can ensure your trailer runs smoothly and safely on the road.

Clean the Bearings and Races

One of the most important steps in greasing your trailer bearings is to clean them thoroughly before applying any new grease. The bearings and races are prone to accumulation of dirt, grime, and contaminants that can affect their performance and eventually cause premature wear and tear. To clean the bearings and races, you can use a high-quality degreaser and a clean rag to wipe off any built-up debris.

Make sure to remove all the old grease, as well as any rust or corrosion that may have formed on the surface. Once the bearings and races are clean, you can apply a fresh coat of grease to ensure smooth operation and maximum protection against friction and heat. Remember to use the recommended type and amount of grease, as well as proper techniques for packing the bearings and adjusting the hub assembly.

By properly cleaning and greasing your trailer bearings, you can extend their lifespan, reduce the risk of breakdowns, and improve your overall towing experience.

– Wipe away any debris with a clean rag – Inspect for any damage or wear – Use a solvent to clean the bearings and races

Cleaning the bearings and races is one of the essential maintenance tasks for keeping your equipment in top shape. To start, wipe away any debris with a clean rag to ensure that you have a clear view of the condition of the bearings and races. Inspect them for any damage or wear, as this will greatly affect their performance.

Use a solvent to clean the bearings and races, making sure to remove any dirt or grime build-up that could lead to friction or damage. Once you have finished cleaning, be sure to reapply lubricant to the bearings to ensure smooth operation. Overall, regularly cleaning and maintaining the bearings and races will extend the life of your equipment and keep it running at its best.

So, take the time to perform this important task, and you’ll see the results in the long run.

Apply Grease

If you want to ensure your trailer stays in good condition while you’re towing, greasing the bearings is a must. But how do you do it? First, you’ll want to jack up the trailer and remove the wheel. Then, clean off any old grease and debris from the bearings with a cloth or brush.

Next, apply grease to the bearings, making sure to use enough but not too much. You want to see a thin layer covering the entire surface. Finally, replace the wheel and repeat on the other side.

It’s important to lubricate your trailer’s bearings regularly to prevent wear and tear on the axles and wheels. By taking the time to grease them, you’ll save yourself from future headaches and costly repairs.

– Put on rubber gloves to protect your hands – Load the grease gun with the recommended grease – Use the gun to apply grease to each bearing by pumping it in until it comes out the other side – Mop up any excess grease with a paper towel

When it comes to maintaining your machinery, ensuring that you apply enough grease is crucial in expanding their lifespan. Grease helps to reduce friction and wear between bearings, creating a lubricating layer between surfaces. To begin, put on a pair of rubber gloves to protect your hands from the grease before loading the grease gun with the recommended amount of grease.

Once you’re all set up, use the gun to apply the grease to each bearing by pumping it in until it comes out the other side. This ensures that each bearing is sufficiently lubricated. In case of any excess, use a paper towel to mop it up, and dispose of it correctly.

Not applying enough grease can result in reduced functionality and increased maintenance costs, but with the recommended amount, your machinery will run smoother and last longer. So don’t forget to grease up and keep your machinery running optimally!

Reinstall Hub and Wheel

One of the most important maintenance tasks for any trailer owner is greasing the bearings. This helps to keep the wheels spinning smoothly and prevents wear and tear on the axle. To get started, you’ll need to jack up the trailer and remove the wheel.

Next, remove the hub and clean any old grease from the bearings. Once everything is clean, you can add fresh grease to the bearings and reinstall the hub and wheel. The process can be a bit messy, but it’s well worth the effort to keep your trailer running smoothly.

Remember to check your bearings regularly and to grease them at least once a year, or more often if you use your trailer frequently. With proper maintenance, your trailer will last for many years to come. So why not take the time today to learn how to grease your trailer bearings and keep your trailer rolling for many more adventures?

– Slide the hub back onto the spindle – Place the washer and nut onto the spindle – Tighten the nut until it is snug, then back it off 1/4 turn – Install the cotter pin – Reinstall the wheel and lugnuts

When it comes to replacing a hub, it’s important to know how to reinstall it properly. Follow these steps to ensure your hub is installed securely. First, slide the hub back onto the spindle, making sure it is centered.

Next, place the washer and nut onto the spindle. Tighten the nut until it is snug, reducing any play in the assembly, then back it off 1/4 turn to allow for thermal expansion and contraction. This will prevent the bearings from overheating and wearing out too quickly due to excessive preload.

Once the nut is backed off, install the cotter pin, bending it so that it holds the nut in place. Finally, reinstall the wheel and lug nuts, tightening them to the manufacturer’s specified torque settings to ensure a safe and secure fit. This process may seem simple, but it is crucial to the overall function of your vehicle.

By taking the time to do it right, you can avoid potential issues down the road and keep your vehicle running smoothly.

Test and Maintenance

One of the most important aspects of maintaining your trailer to ensure a safe and efficient journey is to routinely grease the trailer bearings. A trailer’s bearings are critical components that allow the wheel to spin smoothly, and when they are not adequately lubricated, they can quickly wear out, leading to severe damage to your trailer. This is why it is essential to know how to grease trailer bearings properly.

The first step is to remove the dust cap, cotter pin, spindle nut, and washer to access the bearings. Once you have access to the bearings, clean them with a rag and check to see if they need to be replaced. Next, fill the hub cavity with high-temperature grease, making sure that you cover the rollers adequately.

Finally, reassemble the various parts, making sure that everything is tightened to the proper torque specifications. By following these steps, you can ensure that your trailer’s bearings are adequately lubricated, reducing the risk of damage and prolonging the lifespan of your trailer.

– Spin the wheel to ensure smooth rotation – Repeat the process for the other wheels – Regularly inspect and grease the bearings to ensure optimal performance

When it comes to ensuring optimal performance for your wheels, testing and maintenance are crucial elements. One essential step in maintaining your wheels is to spin the wheel to check for smooth rotation. This step is important because it allows you to identify any potential issues before they turn into larger problems that could compromise your safety.

Repeat this process for all of your wheels to ensure they are all in good working condition. Additionally, regularly inspecting and greasing the bearings can prolong the life of your wheels and keep them performing at their best. By taking these small but important steps, you can save yourself from costly repairs and ensure that your wheels are always in excellent condition.

Remember to keep up with regular maintenance and inspections to keep your wheels spinning like new.

Conclusion

In conclusion, greasing your trailer bearings is a crucial task that requires precision and care. While it may seem like a daunting task, with the right tools and a little bit of know-how, anyone can do it. Just remember to always follow the manufacturer’s guidelines, use high-quality grease, and inspect your bearings regularly.

With proper maintenance, you’ll be able to hit the road with confidence, knowing that your trailer is running smoothly and ready for any adventure ahead. So go ahead, get your hands dirty, and give those bearings the grease they deserve!”

FAQs

Why is it important to grease trailer bearings?

Greasing trailer bearings reduces friction and heat buildup, which prevents premature wear and tear and extends the life of the bearings.

How often should you grease trailer bearings?

It is recommended to grease trailer bearings at least once a year or every 10,000 miles, whichever comes first. However, the frequency may vary depending on usage and manufacturer recommendations.

What type of grease should be used for trailer bearings?

The ideal grease for trailer bearings is a high-temperature, water-resistant, and heavy-duty grease designed for wheel bearings. It should have a lithium complex or synthetic base with a minimum NLGI grade of 2.

Can I over-grease trailer bearings?

Yes, over-greasing trailer bearings can be as harmful as under-greasing. It can cause the grease to leak out, create excess heat and pressure, and damage the seals and bearings. Follow the manufacturer’s instructions and use the correct amount of grease.

How do I know when to replace trailer bearings?

Signs of worn or damaged trailer bearings include unusual noise, vibration, and heat from the hubs. You may also notice uneven tire wear, wobbling, or wheel locking. Inspect the bearings regularly and replace them as needed.

Can I grease trailer bearings myself, or should I seek professional help?

Greasing trailer bearings is a relatively simple DIY task, but it does require some skills, tools, and knowledge. If you feel confident and comfortable, you can do it yourself following the proper guidelines. However, if you are unsure or inexperienced, it’s best to seek professional help.

Is it necessary to pack trailer bearings, or can I use a grease gun?

Packing trailer bearings involves manually filling the gaps and spaces in the bearings with grease, which ensures even distribution and better coverage. While a grease gun can be used for a quick and easy way to add grease, it does not necessarily pack the bearings as thoroughly as packing them by hand.