Are you a truck driver looking to add some convenience and power to your semi? Well, installing a power inverter might just be the solution you need! A power inverter is a device that converts DC power from your truck’s battery into AC power that can be used to run household appliances and electronics. It’s like having a portable electrical outlet in your truck! Whether you want to charge your phone, use a laptop, or even power a mini-fridge, a power inverter can make your life on the road a whole lot easier. In this blog post, we’ll walk you through the process of installing a power inverter in your semi, so you can start enjoying the benefits of portable power right away.

So let’s get started and power up your truck!

Table of Contents

Introduction

Interested in powering your devices on the road? Installing a power inverter in your semi truck can give you the convenience of using electrical appliances while you’re on the go. Whether you want to charge your laptop, run a small refrigerator, or use other electronics, a power inverter can provide you with the necessary electricity. So, how do you go about installing one? Well, the first step is selecting the right power inverter for your needs.

Consider the wattage requirements of the devices you plan to run, and choose an inverter that can handle that power. Then, locate a suitable spot to mount the inverter, such as under the seat or in the sleeper area. Make sure to secure it properly to prevent any movement during travel.

Next, connect the inverter to your truck’s battery using thick-gauge cables. Finally, connect the inverter to the devices you want to power using appropriate electrical cords. As with any electrical installation, it’s important to follow safety precautions and consult the manufacturer’s instructions.

With a power inverter installed, you’ll never have to worry about running out of juice on the road again.

What is a Power Inverter and Why Do You Need It?

power inverter, need

Choosing the Right Power Inverter for your Semi

“When it comes to outfitting your semi-truck with the right power inverter, making the right choice is essential. A power inverter is a device that converts DC power from your truck’s battery into AC power, allowing you to power appliances and devices while on the road. However, not all power inverters are created equal, and it’s important to choose one that meets your specific needs.

Whether you’re looking to power a small refrigerator or a larger appliance, there are several factors to consider when selecting the right power inverter for your semi-truck.”

Step 1: Gather the Necessary Tools and Materials

Are you tired of not being able to charge your electronics while on the road? Installing a power inverter in your semi truck can solve that problem! To get started, you will need a few tools and materials. First, you will need a power inverter that is designed for use in vehicles. Make sure to choose one that has enough wattage to power all of your devices.

You will also need a set of wire cutters, wire strippers, and crimping tools. These will be used to connect the inverter to your truck’s electrical system. Additionally, you will need some electrical tape or heat shrink tubing to insulate the connections.

Finally, it’s a good idea to have some zip ties or mounting brackets to secure the inverter in place. Once you have all of these tools and materials gathered, you will be ready to start the installation process.

List of Tools

List of Tools To begin a project, it is essential to gather all the necessary tools and materials beforehand. Having everything you need within reach will save you time and make the process much smoother. Here is a list of tools that you may need for various projects:

Screwdriver set: A good set of screwdrivers with different sizes and types (flathead and Phillips) will come in handy for most projects involving screws. Hammer: A sturdy hammer is a must-have tool for any DIY project.

It can be used for various tasks, such as driving nails or removing old nails. Tape measure: Accurate measurements are crucial in any project, so having a tape measure on hand is essential.

It will help you ensure that everything fits properly and is aligned correctly. Level: A level is used to determine if a surface is even or straight.

It is especially useful when hanging pictures, shelves, or other items that need to be aligned correctly. Power drill: A power drill is a versatile tool that can be used for drilling holes and driving screws.

Make sure to have a variety of drill bits in different sizes and materials. Pliers: Pliers are handy for gripping, bending, and cutting wires or other small objects.

List of Materials

List of Materials In order to successfully complete any DIY project, it’s important to gather all the necessary tools and materials ahead of time. For this particular project, you will need the following materials: – Wood: You will need a piece of wood that is sturdy and durable. This will be the base for your project, so choose a size that suits your needs.

– Screws: To secure the different parts of your project together, you’ll need screws. Make sure to choose screws that are the appropriate size and length for the thickness of your wood. – Paint or Stain: If you want to add some color or protect your wood, you can use paint or stain.

Choose a color that matches your style and the look you want to achieve. – Sandpaper: Before applying any paint or stain, you’ll want to smooth out any rough edges or imperfections in the wood. Sandpaper in varying grits will allow you to achieve a smooth and polished finish.

– Drill: A drill will be necessary to create holes for the screws. Make sure to have the appropriate drill bit size for the screws you are using. – Screwdriver: A screwdriver will be needed to tighten the screws and secure the different parts of your project together.

– Measuring tape: Accurate measurements are crucial for a successful project. Use a measuring tape to ensure that your wood is cut to the correct size and that all the different parts are properly aligned. – Paintbrushes: If you choose to paint your project, you’ll need paintbrushes to apply the paint evenly and smoothly.

– Safety equipment: Working with wood and tools can be dangerous, so it’s important to protect yourself. Safety glasses, gloves, and a dust mask are essential to keep your eyes, hands, and lungs safe during the project. Now that you have compiled all the necessary tools and materials, you are ready to move on to the next step: planning and measuring your project.

Step 2: Prepare the Semi for Installation

So, you’ve decided to install a power inverter in your semi-truck. Great choice! With a power inverter, you can easily convert the DC power from your truck’s battery into AC power, allowing you to charge your devices or run small appliances while on the road. Now that you have your power inverter ready, it’s time to prepare your semi for installation.

First, start by gathering all the necessary tools and equipment, such as wire cutters, crimping tools, electrical tape, and zip ties. Next, locate a suitable location in your truck to mount the power inverter. It should be close to the battery to minimize the length of the cables needed.

Additionally, make sure there is enough space around the inverter for proper ventilation to prevent overheating. Once you have chosen the ideal spot, clean the area and remove any debris or obstacles. Finally, disconnect the negative terminal of your truck’s battery to ensure your safety during the installation process.

By taking these steps to prepare your semi, you’ll be well on your way to enjoying the convenience of a power inverter on the road.

Locate a Suitable Mounting Location

When it comes to installing a semi truck camera system, choosing the right mounting location is crucial. This step is all about finding the perfect spot on your semi to install the camera system. There are a few factors to consider when determining the ideal location.

One important consideration is visibility – you want to make sure the camera has a clear view of the road ahead and any blind spots. Another factor to keep in mind is durability – the mounting location should be secure and able to withstand the vibrations and jolts of the road. A common mounting location is the dashboard, as it provides a stable platform and easy access to the camera controls.

However, you may also consider other options such as the windshield or side mirrors. Ultimately, the choice of mounting location will depend on your specific needs and preferences. So take the time to carefully evaluate your options and find the perfect spot to install your semi truck camera system.

Prepare the Mounting Surface

In order to properly install a semi-truck, it is essential to have a well-prepared mounting surface. This step is crucial as it ensures the stability and safety of the semi-truck. First, you need to clear the area where the semi-truck will be parked.

Remove any debris, rocks, or other obstacles that could potentially interfere with the placement of the truck. Next, inspect the ground to make sure it is level and even. Uneven surfaces can lead to a tilted truck, which can cause stability issues and potentially damage the truck or its cargo.

If needed, use a leveling tool to adjust the ground or consider using concrete or asphalt to create a stable foundation. Finally, make sure the area is free from moisture or loose soil that could affect the stability of the truck. Preparing the mounting surface properly is vital to ensure a safe and secure installation of the semi-truck.

Step 3: Connect the Power Inverter

Now that you have prepared the necessary tools and materials, it’s time to move on to step three: connecting the power inverter in your semi-truck. This step is crucial for getting the electricity flowing and ensuring that your power inverter is ready to use. Here’s how you can do it.

First, locate the power inverter in your semi-truck. It is usually installed in the cabin or under the seat. Once you’ve found it, make sure your truck is turned off and the keys are out of the ignition.

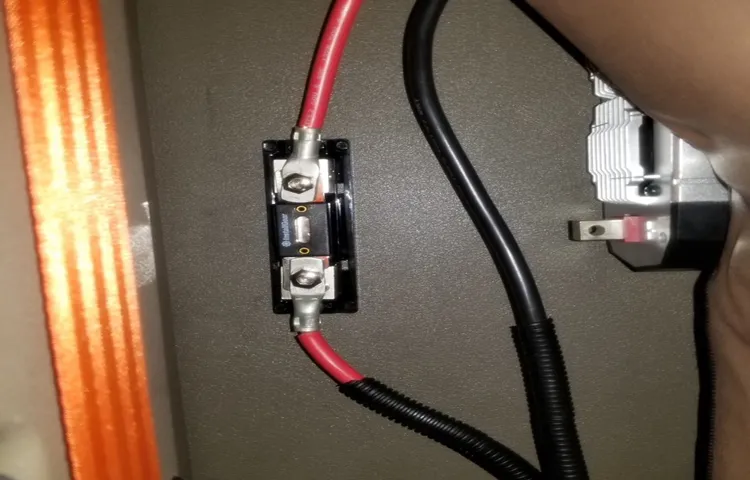

Then, connect the positive (red) cable from the power inverter to the positive terminal of your truck’s battery. Similarly, connect the negative (black) cable from the power inverter to the negative terminal of the battery. Make sure the connections are secure and tight.

Double-check your connections to avoid any accidents or short-circuits. Once you’re satisfied with the connections, turn on your truck and test the power inverter to ensure it’s working properly. That’s it – you’re ready to start using your power inverter in your semi-truck!

Identify the Positive and Negative Battery Terminals

power inverter, Positive and Negative Battery Terminals

Connect the Power Inverter to the Battery

power inverter, connect, battery So now that you’ve got all the necessary tools and materials ready, it’s time to connect your power inverter to the battery. This step is crucial for getting your inverter up and running, so pay close attention! First, make sure your vehicle’s engine is turned off to avoid any accidents. Then, locate the positive and negative terminals on your battery.

The positive terminal is typically marked with a plus sign (+), while the negative terminal is marked with a minus sign (-). Before making any connections, it’s important to wear gloves and eye protection to ensure your safety. Start by connecting the positive cable from the power inverter to the positive terminal of the battery.

You can use a wrench or pliers to secure the connection. Then, do the same with the negative cable, connecting it to the negative terminal of the battery. Again, make sure the connection is tight and secure.

And just like that, you’ve successfully connected your power inverter to the battery! Now you’re one step closer to enjoying all the benefits of having an inverter in your vehicle.

Step 4: Install the Additional Components

Once you have installed the power inverter in your semi truck, it is time to move on to the additional components. These components will help ensure that your power inverter functions properly and safely. One important component to install is a fuse or circuit breaker.

This will protect your inverter from any electrical surges or overloads. You will also need to connect the inverter to your truck’s battery. This involves installing heavy-duty cables and terminals.

Make sure to use the correct gauge of wire for this connection to ensure efficient power transfer. Additionally, you may want to install a remote on/off switch for easy control of your inverter. This switch will allow you to turn the inverter on and off without having to climb into the truck.

Overall, these additional components will enhance the functionality and safety of your power inverter in your semi truck.

Connect the Inverter to the Fuse Box

In step four of installing a solar power system, we will be connecting the inverter to the fuse box. The inverter is an essential component that converts the Direct Current (DC) electricity generated by the solar panels into Alternating Current (AC) electricity that can be used to power your home. This conversion is necessary because most household appliances and electronics run on AC power.

To connect the inverter to the fuse box, you will need to locate an empty space in the fuse box where you can install a circuit breaker. This circuit breaker will act as a disconnect switch between the inverter and the electrical grid. It is important to install a circuit breaker with the appropriate amperage rating, as this will ensure the safety and efficiency of your solar power system.

Once the circuit breaker is installed, you will need to run a conduit or cable from the inverter to the fuse box. This conduit or cable should be properly sized to handle the current load of your solar power system. It is also important to follow any local electrical codes and regulations when routing the conduit or cable.

After the conduit or cable is routed, you can then connect the wires from the inverter to the circuit breaker in the fuse box. This will establish the connection between the inverter and the electrical grid. Finally, it is important to test the connection to ensure that everything is working properly.

This can be done by monitoring the output of the inverter and checking for any errors or warning messages. If everything is functioning correctly, you can then secure the wires and close up the fuse box. Connecting the inverter to the fuse box is a crucial step in the installation process.

It allows the solar power system to safely and efficiently deliver electricity to your home. By following the proper steps and guidelines, you can ensure that your solar power system is connected correctly and ready to provide clean, renewable energy for years to come.”

Connect the Inverter to the Dc Power Source

In this step, we will be installing the additional components needed to connect the inverter to the DC power source. These additional components include cables, connectors, and mounting hardware. First, you will need to gather all the necessary components.

Make sure you have the correct gauge of cables for your specific inverter and power source. The gauge of the cable refers to its thickness, and it is important to use the right gauge to ensure proper power transmission and avoid overheating. Next, you will need to connect the cables to the inverter.

The inverter will have terminals or connectors labeled “Positive” and “Negative” or “Red” and “Black”. Take the positive cable and connect it to the positive terminal or connector on the inverter. Then, take the negative cable and connect it to the negative terminal or connector on the inverter.

Once the cables are connected to the inverter, you will need to route them to the DC power source. This may require drilling holes or using cable clamps to secure the cables in place. Make sure to route the cables in a way that avoids any sharp edges or potential damage from moving parts.

Finally, you will need to connect the cables to the DC power source. If the DC power source has terminals, you can connect the cables directly to the terminals. If the DC power source does not have terminals, you may need to use connectors to attach the cables securely.

Once all the cables are securely connected, you can proceed with securing any loose cables and mounting the inverter in its final location. Make sure to double-check all the connections before turning on the power source. With these additional components installed, your inverter should now be properly connected to the DC power source.

Step 5: Test the Power Inverter

So, you’ve made it to step 5 of installing a power inverter in your semi-truck – testing the power inverter. This is an important step to ensure that everything is working correctly before hitting the road. Before testing, make sure you have properly connected the power inverter to your truck’s battery and all the necessary electrical connections are secure.

Once that’s done, it’s time to see if your power inverter is providing the AC power you need to run your devices. To test it, plug in a small electrical device, such as a phone charger or a small lamp, into one of the AC outlets on the power inverter. If the device turns on and functions properly, then congratulations – your power inverter is working correctly! If not, double-check your connections and make any necessary adjustments.

It’s always a good idea to test your power inverter before hitting the road to avoid any unexpected issues while on the move. So take the time to test it thoroughly, and once you’re confident it’s working correctly, you’re ready to enjoy the convenience and versatility of having AC power in your semi-truck!

Check the Power Output

power inverter, test power output, inverter functions, power supply, inverters work, testing process, solar power systems, electrical devices, power inverter specifications, testing equipment, modified sine wave inverters, pure sine wave inverters, digital multimeter, power inverter operation, safety precautions. In order to ensure that your power inverter is properly functioning, it’s important to test its power output. This step is essential because it allows you to verify whether your inverter is providing the correct amount of power to your electrical devices.

Testing the power output of your inverter is a straightforward process that can be done with the help of a few tools. The first thing you’ll need is a digital multimeter. This handy device will allow you to measure the voltage and current output of your power inverter.

Before you begin testing, it’s important to review the specifications of your inverter to understand the expected power output. Both modified sine wave inverters and pure sine wave inverters operate differently and have unique power supply requirements. To test the power output, start by connecting the positive (red) probe of the multimeter to the positive (red) terminal of the inverter.

Then, connect the negative (black) probe of the multimeter to the negative (black) terminal of the inverter. Make sure to take the necessary safety precautions when working with electrical equipment. Once the connections are secure, turn on the power inverter and observe the readings on the multimeter.

The voltage reading should match the specifications provided by the manufacturer. If the voltage reading is significantly lower or higher than the expected value, it could indicate a problem with the inverter’s operation. Next, use the multimeter to measure the current output of the power inverter.

This will give you an idea of how much power the inverter is supplying to your electrical devices. Compare the current reading with the power requirements of the devices you plan to use with the inverter. If the current output is insufficient, you may need to consider using a different power inverter or adjusting your power requirements.

Test the Inverter with Different Appliances

The next step in testing your power inverter is to connect it to different appliances and see how it performs. This will give you a better idea of its capabilities and help you determine if it’s suitable for your needs. Start by connecting a small electrical device, such as a cellphone charger, to the inverter.

Turn on the inverter and observe if the device powers up and charges properly. If it does, this is a good sign that the inverter is functioning correctly. Next, try connecting a larger appliance, such as a laptop or a small television.

Again, observe if the appliance powers up and works as expected. If everything seems to be working fine, you can feel confident in the performance of your power inverter. However, if you encounter any issues or the appliances don’t work properly, it may indicate that the inverter is not suitable for the specific devices you want to use with it.

It’s important to test a variety of appliances to ensure your inverter can handle the power load and provide consistent, reliable performance.

Conclusion

In conclusion, installing a power inverter in a semi is like giving your truck a superhero upgrade. Just picture it: cruising down the open road, your trusty semi now equipped with the power to charge your devices, run appliances, and feel like a mobile command center. It’s like having Tony Stark’s Iron Man suit for your truck.

So go forth, my fellow road warriors, and embrace the power of the power inverter. Your semi will thank you, and you’ll feel like a true hero of the highway.”

Enjoy the Benefits of a Power Inverter in Your Semi

power inverter, test, benefits, semi truck, Enjoy

FAQs

How do I install a power inverter in a semi-truck?

To install a power inverter in a semi-truck, first, determine the appropriate location for the inverter, ensuring it is securely mounted. Then, connect the inverter to a power source, such as the truck’s battery, following the manufacturer’s instructions. Finally, connect your desired devices to the inverter, making sure to use the appropriate cables and fuses for safety.

What size power inverter do I need for a semi-truck?

The size of the power inverter you need for a semi-truck depends on your power requirements. Consider the devices you will be powering and their wattage. Generally, a 1500-watt power inverter should be sufficient for basic electronic devices such as laptops, phones, and small appliances. However, if you plan to power larger devices or multiple devices simultaneously, you may need a higher wattage inverter.

Can I install a power inverter in a semi-truck myself, or do I need professional help?

The installation of a power inverter in a semi-truck can be done by either a professional or yourself if you have the necessary knowledge and experience with electrical systems. However, if you are uncertain or not confident in your abilities, it is recommended to seek professional help to ensure the installation is done correctly and safely.

What are the benefits of installing a power inverter in a semi-truck?

Installing a power inverter in a semi-truck allows you to have access to AC power while on the road. This can be beneficial for various reasons, such as charging electronic devices, powering appliances, running tools, and even providing a power source during emergencies. It provides convenience, flexibility, and extends the functionality of your semi-truck.

Can a power inverter drain the battery of a semi-truck?

Yes, a power inverter can potentially drain the battery of a semi-truck if an excessive load is connected or if the inverter is left on for an extended period without the engine running. It is important to be mindful of the power consumption of the connected devices and to turn off the inverter when not in use to prevent unnecessary battery drain.

What safety precautions should I take when installing a power inverter in a semi-truck?

When installing a power inverter in a semi-truck, it is important to observe safety precautions. These include disconnecting the truck’s battery before beginning the installation, using appropriate wires and cables with the correct amp rating, ensuring proper grounding, and installing fuses or circuit breakers to protect the inverter and connected devices from electrical faults.

Can a power inverter in a semi-truck be used while driving?

Yes, a power inverter in a semi-truck can be used while driving. However, it is important to ensure that the inverter is securely mounted and properly connected to a power source, and the connected devices are situated safely to prevent any distractions while driving.