If you are a car enthusiast or someone who enjoys adding personal touches to their vehicle, installing running board lights can be a fun and practical project. Not only do these lights enhance the appearance of your car, but they also provide additional visibility and safety when getting in and out of your vehicle at night. But how exactly do you go about installing running board lights? In this blog post, we will guide you through the step-by-step process of installing these lights, making it easy and straightforward for you to upgrade your car’s exterior.

So, grab your tools and let’s get started!

Table of Contents

Introduction

If you want to add some extra flair to your vehicle, installing running board lights is a great way to do it. These lights not only enhance the aesthetic appeal of your car or truck but also improve visibility and safety. Installing running board lights may seem like a daunting task, but with the right tools and a little patience, you can do it yourself.

In this blog post, we will guide you through the steps of installing running board lights, from choosing the right lights to wiring them properly. So, let’s get started and make your vehicle stand out on the road!

What are running board lights?

Running board lights are a type of auxiliary lighting that is typically installed on the sides of vehicles, specifically on the running boards or the step bars. These lights serve multiple purposes, including providing additional visibility and safety, enhancing the overall appearance of the vehicle, and improving functionality for passengers getting in and out of the vehicle. Running board lights are usually LEDs and come in various colors and styles to suit different preferences and requirements.

In addition to their practical uses, running board lights are also popular among car enthusiasts who want to customize their vehicles and give them a unique and stylish look. Whether you are looking for increased safety or a way to jazz up your ride, running board lights are a fantastic option to consider.

Why install running board lights?

running board lights. Introduction: Installing running board lights on your vehicle can add both style and functionality to your ride. These small but mighty lights are mounted on the sides of your vehicle’s running boards, providing enhanced visibility and safety, especially during nighttime or low-visibility conditions.

Whether you’re a fan of off-roading adventures or simply want to make your vehicle stand out from the crowd, running board lights are a worthwhile addition. In this blog, we will explore the reasons why you should consider installing running board lights and how they can enhance your overall driving experience. So, buckle up and read on to discover the benefits of these illuminating accessories.

Materials Needed

If you’re looking to add some flair to your vehicle and increase visibility at night, installing running board lights is a great option. Before you begin the installation process, it’s important to gather all the necessary materials. Here’s a list of what you’ll need: running board lights (make sure you choose lights that are LED and waterproof for durability), a drill and drill bits (to make holes for the lights), wire connectors (to connect the lights to your vehicle’s electrical system), a wire stripper and crimper (to properly connect the wires), and electrical tape (to secure the connections and prevent any short circuits).

Additionally, you’ll need some basic hand tools such as a screwdriver, wrench, and pliers. By having all these materials on hand, you’ll be well-prepared to tackle the installation process and have your running board lights up and running in no time.

Running board lights kit

Running board lights kit

Screwdriver

“Screwdriver”

Electric drill

electric drill

Wire crimper

“wire crimper” One of the essential tools for anyone working with electrical wiring is a wire crimper. This handy tool allows you to securely attach connectors to the ends of wires, ensuring a strong and reliable electrical connection. But what materials do you need to use a wire crimper effectively? First and foremost, you’ll need the wire crimper itself.

Wire crimpers come in various sizes and types, so it’s crucial to choose one that is suitable for the gauge of wire you’ll be working with. A good quality wire crimper will have multiple crimping slots to accommodate different connector sizes. Next, you’ll need the connectors or terminals that you’ll be attaching to the wires.

These can come in various shapes, sizes, and types, depending on the specific application. For example, if you’re working with stranded wire, you’ll need connectors designed for that type of wire. It’s essential to ensure that you have the correct connectors for the wire you’re using to achieve a secure and proper connection.

In addition to the wire crimper and connectors, you’ll also need a wire stripper. This tool is used to remove the insulation from the end of the wire, allowing for a clean and secure connection. A wire stripper typically has multiple cutting and stripping sizes, accommodating different wire gauges.

Finally, you’ll need wire cutters or pliers to trim the excess wire and ensure a neat and tidy finish. These tools are essential for achieving a professional-looking result. By having all these materials on hand, you’ll be well-equipped to use a wire crimper effectively.

Whether you’re a professional electrician or a DIY enthusiast, the right tools will make all the difference in your electrical projects. So, gather your wire crimper, connectors, wire stripper, and wire cutters, and get ready to tackle any electrical wiring job with confidence.

Preparation

If you’re looking to add some extra flair to your vehicle, installing running board lights is a great way to do it. These lights not only enhance the appearance of your vehicle but also provide additional safety and visibility, especially at night. But how do you go about installing them? To start, you’ll need to gather all the necessary tools and materials.

This includes running board lights, wiring harnesses, a soldering iron, electrical tape, and a drill with various-sized drill bits. It’s important to ensure that the lights you choose are compatible with your vehicle’s make and model. Once you have everything you need, you can begin the installation process.

Start by positioning the running board lights along the underside of your vehicle’s running boards. Make sure to choose a spot that is easily accessible for wiring. Next, use a marker or pencil to mark the areas where you’ll need to drill holes for the wiring.

After you have marked the spots, carefully drill the holes using the appropriate drill bit size. Be sure to drill straight and avoid damaging any existing wiring or components. Once the holes are drilled, you can begin wiring the lights.

Start by connecting the wiring harnesses to the lights and then running them along the underside of the running boards towards the nearest power source. You may need to remove some trim or panels to access the power source, so take your time and be careful not to damage anything. Once you have reached the power source, which is usually the vehicle’s battery or fuse box, you will need to connect the wires.

It’s important to follow the instructions provided with the wiring harness and lights to ensure a secure and proper connection. This may involve soldering or using wire connectors and electrical tape. After all the wiring is connected and secure, test the lights to make sure they are working properly.

Choose the type of lights

When it comes to lighting up your home or workspace, choosing the right type of lights is essential. There are several options available, each with its own unique characteristics and benefits. One popular choice is LED lights, which are known for their energy efficiency and long lifespan.

LED lights are also versatile and can be used in a variety of settings, from ambient lighting to task lighting. Another option is fluorescent lights, which are often used in larger spaces due to their bright and even light distribution. Fluorescent lights are also energy efficient and have a longer lifespan compared to traditional incandescent bulbs.

Lastly, there are halogen lights, which are known for their bright and intense light output. These lights are commonly used in spotlights and accent lighting. When choosing the type of lights for your space, it’s important to consider factors such as the purpose of the lighting, the desired ambiance, and energy efficiency.

Measure the running board length

running board length, preparation, measure, measuring tape

Clean the running board surface

clean running board surface, preparation

Installation Steps

Installing running board lights is a relatively simple process that can greatly enhance the look and functionality of your vehicle. To begin, gather all the necessary tools and materials, including the running board lights kit, a drill with a small drill bit, and electrical tape. Start by measuring and marking the desired locations for the lights on your running boards.

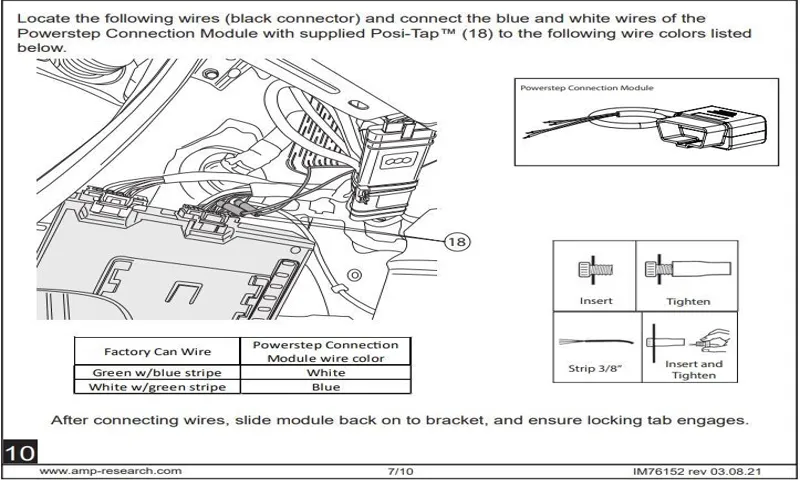

Once marked, use the drill to create holes for the lights to be installed. Carefully feed the wires through the holes and secure them in place using electrical tape to prevent them from dangling or getting caught. Next, connect the wires from the lights to the corresponding wires in your vehicle’s electrical system.

This can usually be done by splicing them together and securing them with electrical tape. Finally, test the lights to ensure they are working properly before securing them in place with screws or adhesive. In no time, you’ll have stylish and functional running board lights that will make your vehicle stand out on the road.

Step 1: Position the lights

led light installation, lights positioning, step by step instructions, lighting placement, DIY lighting setup, lighting tips

Step 2: Drill mounting holes

drill mounting holes When it comes to mounting anything, one of the crucial steps is drilling the right holes. Whether you’re hanging shelves, installing a TV wall mount, or putting up a new light fixture, drilling mounting holes is essential for a secure and stable installation. But how do you do it right? Well, let’s break it down into simple steps.

First, you’ll need to gather the necessary tools, including a power drill, the correct drill bit size for your screws or anchors, a tape measure, and a pencil. Once you have everything ready, make sure you have a clear plan of where you want to mount your item. Measure the distance between the holes and mark the exact spot on the wall with a pencil.

Then, it’s time to drill. Start by selecting the appropriate drill bit size and attach it to your power drill. Position the drill bit on the marked spot and apply gentle pressure as you drill into the wall.

Take your time and let the drill do the work. Make sure to drill straight and at a 90-degree angle to ensure the holes are aligned correctly. Once you’ve drilled the holes, clean up any debris and check if they are the right size and depth for your screws or anchors.

If they’re too small, you may need to use a larger drill bit. But if they’re too big, you might need to patch and redrill the holes. So, take your time and double-check before proceeding.

Remember, drilling mounting holes is a crucial step that determines the stability and durability of your installation. So, be patient, measure twice, and drill once to achieve a perfect mount.

Step 3: Connect wiring

When it comes to installing a new electrical fixture or appliance, connecting the wiring is a crucial step. This is where you will need to make the necessary electrical connections to ensure that the device receives power and functions properly. It’s important to note that working with electrical wiring can be dangerous if not done correctly, so it’s always a good idea to consult a professional electrician if you’re unsure.

To start, you will need to gather the necessary tools, such as wire cutters, wire strippers, and electrical tape. Next, you’ll want to turn off the power to the area where you’ll be working by flipping the corresponding circuit breaker in your electrical panel. This is a critical safety precaution that will protect you from any potential electrical shocks.

Once the power is off, you can begin by stripping the ends of the wires that need to be connected using wire strippers. After stripping the wires, you can then connect them by twisting the exposed ends together and securing them with wire nuts. Finally, you’ll want to wrap electrical tape around the wire connections to provide an extra layer of insulation and protection.

Once you’ve completed the wiring connections, you can turn the power back on and test the device to ensure that it is working properly. By following these steps and taking the necessary safety precautions, you can successfully connect the wiring for your electrical installation.

Step 4: Secure lights with screws

One important step in the installation process of outdoor lights is to secure the lights with screws. This ensures that the lights are firmly attached and won’t come loose over time. To do this, you will need to use the appropriate screws for the type of lights you are installing.

Generally, outdoor lights come with mounting brackets or plates that have holes for screws. Simply align the holes on the bracket with the pre-drilled holes on the surface where the lights will be installed, and then insert the screws into the holes. Make sure to tighten the screws securely, but be careful not to overtighten and damage the lights or the mounting surface.

By securing your outdoor lights with screws, you can have peace of mind knowing that they will stay in place and provide reliable illumination for years to come.

Step 5: Test the lights

The final step in installing your lights is testing them to ensure they are working properly. This is an important step to take before completing the installation process. Start by turning on the power to the lights and checking that they illuminate.

You can also check for any loose or broken connections, as well as any flickering or dimming of the lights. If everything appears to be in working order, continue to test the different features of the lights, such as different colors or brightness levels. This will help you ensure that the lights are functioning as intended.

If you notice any issues or defects, it is important to address them before completing the installation. Testing the lights will give you peace of mind and ensure that you can fully enjoy their beauty once they are installed.

Tips and Troubleshooting

Installing running board lights on your vehicle can not only enhance its appearance but also improve safety. If you are wondering how to install running board lights, there are a few steps you can follow to accomplish this task. First, gather all the necessary tools and equipment, including the running board lights kit, a measuring tape, a drill, and wiring connectors.

Next, measure and mark the desired locations for the lights on your vehicle’s running boards. Once you have determined the placement, use the drill to create holes for the lights. After that, connect the running board lights to the vehicle’s electrical system using the wiring connectors.

Make sure to follow the instructions provided with the lighting kit for proper installation. Finally, test the lights to ensure they are working correctly before reassembling any parts. By following these steps, you can easily install running board lights on your vehicle and enjoy the benefits they provide.

Properly seal the lights to prevent moisture

One important tip to keep in mind when it comes to outdoor lights is to properly seal them to prevent moisture. Moisture can be detrimental to the longevity and functionality of your lights, as it can lead to rust, corrosion, and even electrical issues. To ensure that your lights stay dry and protected, it is crucial to use a waterproof sealant or silicone around the edges and connections of the lights.

This will create a tight and secure seal, preventing any water or moisture from seeping into the lights. Additionally, inspect your lights regularly to make sure the sealant is intact and in good condition. If you notice any cracks or areas where the sealant has deteriorated, be sure to reseal those areas promptly.

By taking these simple steps, you can effectively protect your outdoor lights from moisture-related damage and ensure that they will continue to illuminate your space for years to come.

Double-check wiring connections before finalizing installation

In the exciting world of installing electrical wiring, it’s important to double-check your connections before finalizing the installation. This step might seem like common sense, but it’s easy to overlook in the rush to finish a project. By taking the time to carefully inspect your wiring connections, you can ensure that everything is properly connected and secure.

This can help prevent future issues like power surges or electrical fires. So, before you close up those walls or put the finishing touches on your electrical panel, take a few extra minutes to give everything a once-over. It’s a small step that can make a big difference in the overall safety and effectiveness of your electrical system.

So, trust me, you’ll be glad you did!

If lights don’t turn on, check fuse connections

lights not turning on, check fuse connections

Conclusion

By now, you should be feeling like a pro at installing running board lights. You have conquered the darkness and transformed your vehicle into a shining beacon of style and safety. Whether you choose to go for a subtle glow or a bold and vibrant display, your running board lights are sure to turn heads and make you the envy of all your friends.

But remember, with great style comes great responsibility, so make sure to follow all local laws and regulations when it comes to using running board lights on public roads. And if anyone asks how you managed to install these fabulous lights, don’t be afraid to share your newfound knowledge and enlighten them on the steps to illuminating their own rides. So go forth, fellow automotive enthusiasts, and light up the road ahead.

Let your running board lights guide you on your adventures and bring a touch of brilliance to your every journey. Happy installing!”

FAQs

What are running board lights used for?

Running board lights are used to provide additional illumination along the sides of a vehicle, especially around the area where passengers enter and exit. They can enhance visibility and safety during nighttime or low-light conditions.

How do running board lights work?

Running board lights typically function as auxiliary lights that are wired into the vehicle’s electrical system. They are usually mounted on the underside of the running boards or along the vehicle’s lower sides. When activated, they emit a beam of light to help illuminate the area around the vehicle’s sides.

Can running board lights be installed on any vehicle?

Yes, running board lights can be installed on most vehicles, including cars, trucks, SUVs, and vans. However, the installation process may vary depending on the specific make and model of the vehicle. It is recommended to refer to the manufacturer’s instructions or consult a professional for proper installation.

Are there different types of running board lights available?

Yes, there are different types of running board lights available. Some common options include LED running board lights, which offer bright and energy-efficient illumination, and halogen running board lights, which provide a warmer and more traditional light. Additionally, there are also lights with different color options or flashing capabilities for added customization.

Can running board lights be installed as a DIY project?

While it is possible to install running board lights as a DIY project, it is recommended to have some technical knowledge and experience with automotive wiring. Improper installation may result in electrical issues or damage to the vehicle. If unsure, it is best to consult a professional for installation or seek guidance from reputable online resources.

Are there any regulations or restrictions regarding running board lights?

Regulations regarding running board lights may vary depending on the country or state. It is important to check local laws and regulations to ensure compliance before installing running board lights. Some jurisdictions may restrict the colors, brightness, or flashing capabilities of these lights to prevent distraction or confusion on the road.

How can I maintain and care for my running board lights?

To maintain and care for running board lights, regular inspection is recommended to ensure they are clean, free from debris, and in proper working condition. When cleaning, use a mild soap and water solution and a soft cloth to avoid scratching the lights. It is also important to check the wiring connections periodically for any signs of damage or corrosion and address issues promptly.