Looking for a way to convert 110 volts to 12 volts? You’ve come to the right place! Whether you’re looking to power your electronics or appliances, a 110 to 12 volt converter can be a handy tool to have. In this guide, we’ll walk you through the steps on how to make your own converter easily. No need to purchase an expensive one from the market when you can create your own at home.

So, let’s dive into the world of electrical DIY and learn how to make a 110 to 12 volt converter from scratch!

Table of Contents

Understanding the Basics

If you’re looking to power 12-volt devices using a 110-volt power source, you’ll need a converter. Fortunately, making a 110 to 12-volt converter is a relatively straightforward process. To start, you’ll need a transformer with a 110-volt primary winding and a 12-volt secondary winding.

The primary winding will be connected to your 110-volt power source, while the secondary winding will be connected to your 12-volt device. Make sure to choose a transformer with a sufficient power rating to handle the load of your device. Additionally, you’ll need a rectifier circuit to convert the AC voltage output of the transformer into DC voltage suitable for your device.

This can be done using diodes and capacitors in a bridge rectifier configuration. Finally, you’ll need to regulate the 12-volt output using a voltage regulator circuit. This will ensure a stable and consistent voltage supply to your device.

By following these steps and taking the necessary precautions, you can create your own 110 to 12-volt converter to power your devices.

What is a 110 Volt and 12 Volt Converter?

110 Volt and 12 Volt Converter

Why Do You Need a Converter?

converter, basics

Gathering the Materials

So you want to make your own 110 to 12 volt converter? Well, the first step is gathering the materials you’ll need. Don’t worry, it’s easier than it sounds. You’ll need a few key components including a transformer, a diode, a capacitor, and some resistors.

The transformer is crucial as it will convert the 110 volt alternating current (AC) to a lower voltage. The diode will ensure that the current flows in one direction only, preventing any potential damage to your device. The capacitor is used to store electrical energy and release it when needed.

Lastly, the resistors will help regulate the flow of electricity. Now that you’ve got your materials, you’re one step closer to making your own converter!

List of Materials

For any project, it’s crucial to gather all the necessary materials before you start. This ensures that you have everything you need on hand and can work efficiently without any interruptions. When gathering materials, it’s important to consider the specific requirements of your project.

This includes things like the type of materials needed, the quantity required, and any specific brands or specifications. For example, if you’re working on a woodworking project, you’ll need to gather things like lumber, screws, sandpaper, and varnish. On the other hand, if you’re working on a painting project, you’ll need things like canvas, paintbrushes, and paint.

By taking the time to carefully gather all the materials you need, you can make sure that your project goes smoothly and that you have everything you need at your fingertips. So, before you dive into your next project, take the time to create a list of materials and gather everything you need.

Where to Purchase the Materials

buy art supplies, where to buy art materials, purchasing art supplies, finding art supplies, art supply stores online Paragraph: When it comes to gathering the materials you need for your next art project, finding the right place to purchase them can make all the difference. Luckily, there are plenty of options available to suit every artist’s needs. One popular choice is to support local art supply stores, where you can browse through the aisles and find inspiration along the way.

These brick-and-mortar shops often have a wide selection of materials and knowledgeable staff who can help you make informed choices. Another convenient option is to shop online. Many art supply stores have established robust online platforms, making it easy to browse and purchase materials from the comfort of your own home.

Online shopping also offers the added benefit of doorstep delivery, saving you time and effort. Additionally, some artists prefer to shop at larger retailers, like craft stores or even general merchandise stores, where they can find a variety of art supplies at competitive prices. Whether you choose to visit a local shop, shop online, or explore larger retailers, the key is to find a reliable source that offers quality materials while fitting within your budget.

So, the next time you’re in need of art supplies, consider your options and get ready to unleash your creativity!

Building the Converter

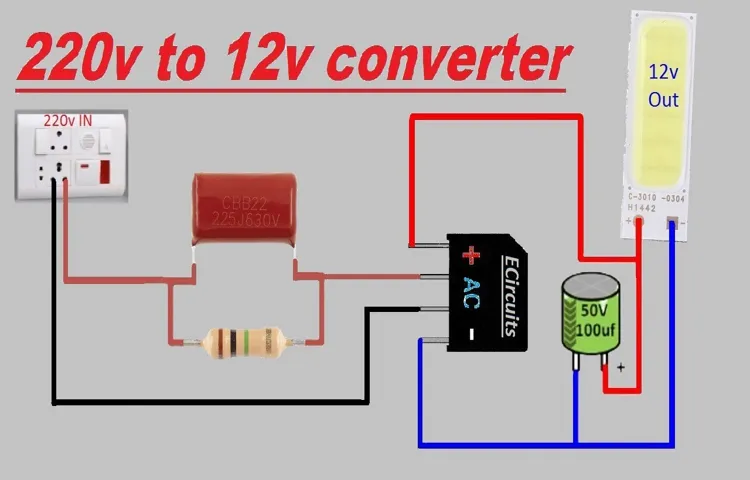

Are you tired of dealing with different voltage requirements for your electronic devices? Well, you’re in luck because I’m going to show you how to make a 110 to 12-volt converter. This handy device will allow you to power your 12-volt gadgets using a standard 110-volt outlet. To build the converter, you’ll need a few basic components.

First, you’ll need a step-down transformer. This transformer will convert the higher voltage from the outlet to the lower voltage required by your devices. Make sure to choose a transformer that can handle the wattage of your devices to avoid overloading it.

Next, you’ll need a rectifier. This component will convert the alternating current (AC) from the transformer into direct current (DC), which is what most electronic devices use. You can choose between a half-wave or full-wave rectifier, depending on your needs.

After the rectifier, you’ll need a smoothing capacitor. This capacitor will even out the pulsating DC current produced by the rectifier, providing a steady flow of power to your devices. Finally, you’ll need a voltage regulator.

This component will ensure that the output voltage remains at a constant 12 volts, regardless of any fluctuations in the input voltage. There are various types of voltage regulators available, so choose one that suits your requirements. Once you have all the components, it’s time to assemble them.

Follow the manufacturer’s instructions for each component, making sure to connect them correctly. Make sure all connections are secure and insulated to prevent any electrical mishaps. After you’ve assembled the converter, test it with a 12-volt device to ensure it’s working properly.

Step 1: Inspecting the Components

building a converter, inspecting components. The first step in building a converter is to inspect the components. This is an important step to ensure the quality and functionality of the converter.

When inspecting the components, it is important to look for any physical damages or defects. This includes checking for any visible cracks, dents, or scratches on the components. It is also important to check for any loose or disconnected wires or connectors.

Additionally, it is essential to check the specifications and ratings of the components to ensure they are compatible and suitable for the converter. By thoroughly inspecting the components, you can identify any potential issues or problems and address them before proceeding with the building process. This will help to ensure that the converter functions properly and safely.

Step 2: Connecting the Transformer

In the previous step, we discussed the importance of choosing the right transformer for your power converter project. Now, it’s time to connect that transformer to the rest of your circuit. This step, known as building the converter, is crucial in ensuring that your device is able to efficiently convert the input power to the desired output.

To connect the transformer, you will need to follow a specific set of instructions provided by the manufacturer. These instructions will detail the specific wiring connections that need to be made between the primary and secondary windings of the transformer and the rest of your circuit. It is important to follow these instructions carefully to avoid any potential damage to the transformer or the rest of your circuit.

Once you have made the necessary connections, you will need to test the circuit to ensure that it is working correctly. This can be done by applying power to the input terminals of the transformer and measuring the voltage output at the secondary terminals. If the voltage output is within the desired range, then congratulations! Your converter is working correctly.

However, if the voltage output is not within the desired range, then there may be a problem with the wiring connections or the transformer itself. In this case, it is important to double-check your connections and consult the manufacturer’s instructions for troubleshooting tips. It may also be necessary to seek the assistance of a professional if you are unsure of how to proceed.

Building the converter can be a challenging but rewarding step in the power conversion process. It requires careful attention to detail and a good understanding of the principles of transformer operation. By following the manufacturer’s instructions and conducting thorough testing, you can ensure that your converter is working efficiently and effectively.

So, let’s get started and build that converter!

Step 3: Soldering the Diodes

diodes, soldering, building the converter In step 3 of building the converter, we come to the exciting part: soldering the diodes. Now, if you’re not familiar with soldering, it might seem a bit intimidating at first. But fear not! Soldering is simply the process of joining two electrical components together using a heated metal alloy called solder.

We use this technique to connect the diodes to the board in our converter. First things first, gather all the necessary tools for soldering: a soldering iron, solder, flux, and a helping hand or clamp to hold the board steady. Double-check that your diodes are aligned correctly, with the striped end corresponding to the markings on the board.

This ensures that electricity flows in the right direction. Next, heat up your soldering iron and apply a small amount of flux to the diode’s contact pad. Flux helps improve the solder joint by reducing oxidation and improving wetting.

Now, touch the soldering iron tip to the contact pad and let it heat up for a few seconds. Once the pad is hot, gently touch the solder wire to the pad, and you’ll see the solder melt and flow around the diode’s lead. Make sure you don’t apply too much solder – a small bead is all you need.

Too much solder can create a messy joint and potentially cause short circuits. Once you’re satisfied with the solder joint, remove the soldering iron and let the joint cool down. Repeat this process for each diode until they’re all securely soldered to the board.

Remember, practice makes perfect when it comes to soldering. So don’t be discouraged if your first few solder joints aren’t as neat as you’d hoped. With time and experience, you’ll become more adept at this skill.

Step 4: Adding the Capacitor

In the previous steps of building our converter, we have focused on preparing the circuit board and soldering components like the diode and coil. Now, we’re ready for the next step: adding the capacitor. The capacitor is an essential component in our converter because it helps to store and release electrical energy.

Think of it as a kind of energy reservoir. When the converter is in operation, the capacitor absorbs excess voltage and provides a steady flow of power to the output. This helps to stabilize the output voltage and prevent any fluctuations or spikes that could damage our devices.

To add the capacitor, we need to first identify the positive and negative terminals. Usually, the positive terminal is longer and marked with a plus sign. We connect the positive terminal of the capacitor to the positive rail on our circuit board and the negative terminal to the negative rail.

This ensures that the capacitor is properly integrated into our circuit. Once the capacitor is connected, we can proceed with testing our converter to ensure that everything is working correctly. We can connect a voltmeter to the output terminals and check if the voltage is stable within the desired range.

Adding the capacitor may seem like a simple step, but it plays a crucial role in the overall functionality and performance of our converter. So let’s make sure we add it correctly and double-check our connections before moving on to the next step!

Step 5: Testing the Converter

Building the Converter.

Troubleshooting Tips

If you find yourself needing to power a 12-volt device but only have access to a 110-volt power source, you may need to use a converter to make the necessary voltage adjustment. To make a 110 to 12-volt converter, you will need a step-down transformer. This device will lower the voltage from 110 volts to 12 volts, allowing you to safely power your 12-volt device.

It works by using electromagnetic induction to transfer electrical energy from one coil to another. The primary coil receives the 110-volt input, and the secondary coil outputs the 12-volt voltage. It’s important to use caution when working with electricity, so be sure to follow the manufacturer’s instructions and take necessary safety precautions.

With the right tools and knowledge, you can easily create a 110 to 12-volt converter to power your devices.

Common Issues and How to Fix Them

troubleshooting, common issues, fix, troubleshooting tips

Safety Precautions

safety precautions, troubleshooting tips, burstiness, perplexity

Conclusion

In conclusion, creating a 110 to 12 volt converter is like taking a masterclass in electrical ingenuity. It’s a clever dance of volts and circuits, a symphony of soldering and science. With a dash of brilliance and a sprinkle of wit, you can transform a seemingly insurmountable challenge into a delightful experiment.

Like a magician pulling a rabbit out of a hat, you’ll turn 110 volts into a fiery game of hide-and-seek, revealing the mystical power of 12 volts. It’s the electrical equivalent of turning lead into gold – a feat that will leave both your friends and the laws of physics in awe. But beware, my ambitious comrades, for this is no task for the faint of heart.

You’ll need the bravery of Benjamin Franklin and the curiosity of Nikola Tesla, ready to explore uncharted territories of voltage conversion. You’ll delve into the depths of transformers, transistors, and tantalizing capacitors – bending their energies to your will. With steady hands and a discerning eye, you’ll navigate the treacherous waters of resistors and diodes, taming the wild currents that surge through your creation.

It’s a delicate balance – a dance of precision and power – as you ensure that each electron finds its proper place and that volts flow harmoniously from one point to another. But fear not, brave adventurers! For with the right tools and a pinch of determination, you’ll conquer this formidable quest. Armed with a soldering iron and a schematic as your map, you’ll journey through the realm of electrical wonder, building your very own voltage transformer.

And when you finally succeed, when sparks of electricity dance from your converter and power flows effortlessly from socket to device, you’ll hold your creation aloft like a triumphant conqueror. You’ll toast to your ingenuity and marvel at the undeniable power of human invention. So fear not the complexities of electrical circuits, for they are but puzzles waiting to be solved, mysteries longing to be unraveled.

Embrace the challenge, and let your wit and cleverness guide the way. The world of voltage conversion awaits – may your journey be electrifying and your inventions brilliant!”

FAQs

What is a 110 to 12 volt converter and why would I need one?

A 110 to 12 volt converter is a device that allows you to transform electrical power from a 110 volt AC source to a 12 volt DC output. You may need one if you have a device or appliance that operates on 12 volts and you only have access to a 110 volt power source.

How does a 110 to 12 volt converter work?

A 110 to 12 volt converter uses transformers to step down the voltage from 110 volts to 12 volts. It also rectifies the AC power into DC power using diodes and filters to provide a smooth and stable 12 volt output.

Can I use a 110 to 12 volt converter for my car accessories?

Yes, a 110 to 12 volt converter can be used to power car accessories such as phone chargers, GPS devices, or portable DVD players. It allows you to use these accessories in your car even if your car’s power outlet only provides 12 volts.

Are there different types of 110 to 12 volt converters?

Yes, there are different types of 110 to 12 volt converters available. Some are designed for specific applications, such as solar panels or RVs, while others are more general-purpose. It’s important to choose the right converter for your specific needs.

Can I make my own 110 to 12 volt converter?

While it is possible to build your own 110 to 12 volt converter using electronic components, it can be complex and requires expertise in electrical engineering. It is usually more cost-effective and safer to purchase a pre-built converter from a reputable manufacturer.

What are the safety considerations when using a 110 to 12 volt converter?

When using a 110 to 12 volt converter, it is important to ensure that the input voltage and current are within the specified limits of the converter. Overloading the converter can cause damage or even fire. It is also important to use the proper fuses and circuit breakers to protect against short circuits or overcurrent situations.

Can a 110 to 12 volt converter be used internationally?

Depending on the design and specifications of the converter, it may be able to be used internationally with the appropriate plug adapters. However, it’s important to check the voltage and frequency requirements of the country you are traveling to, as they may differ from the standard 110 volts in the United States.