Hey there! Have you ever wondered how you can power up your devices when you’re on the go, away from an electrical socket? Well, that’s where power inverters come in! In this blog, we’re going to dive into the world of power inverters and explore how they work, their benefits, and how they can make your life a whole lot easier. Imagine this scenario: you’re on a road trip with your friends and your phone battery is about to die. You desperately need to charge it, but there’s no outlet in sight.

This is where a power inverter can save the day. A power inverter is a device that converts direct current (DC) power from your vehicle’s battery into alternating current (AC) power, similar to what you have in your home. This means you can plug in your phone charger, laptop, or any other AC-powered device and charge it up, even when you’re on the move.

Think of a power inverter as a translator between your car’s electrical system and your everyday devices. It takes the power from your car’s battery, which is in the form of DC, and converts it into AC power that your devices can use. It’s like having a universal power adapter for your car! One of the great things about power inverters is their versatility.

They come in various sizes and power capacities, so you can choose the one that best suits your needs. Whether you want to charge a small electronic device or power up larger appliances like a mini-fridge or even a power tool, there’s a power inverter out there for you. Not only are power inverters convenient for road trips, but they also come in handy during power outages or when you’re camping in the great outdoors.

With a power inverter, you can keep your essential devices charged and running, ensuring you’re never left in the dark. So, if you’re someone who loves to be prepared and always wants to have power at your fingertips, a power inverter is definitely something worth considering. Stay tuned as we explore more about the different types of power inverters, their features, and how to choose the right one for your needs.

Get ready to unleash the power of technology wherever you go!

Table of Contents

- 1 What is a Power Inverter?

- 2 Why Make Your Own Power Inverter?

- 3 Safety Precautions to Consider

- 4 Input Stage Components

- 5 Output Stage Components

- 6 Designing the Circuit

- 7 Soldering the Components

- 8 Assembling the Inverter

- 9 Testing the Circuit

- 10 Troubleshooting Common Issues

- 11 Tips for Success

- 12 Further Explorations

- 13 Final Thoughts

- 14 Conclusion

- 15 FAQs

What is a Power Inverter?

If you’re wondering how to make your own power inverter, you’re in luck! A power inverter is a device that converts direct current (DC) power from a battery into alternating current (AC) power that can be used to run household appliances and electronics. Making your own power inverter can be a fun and rewarding DIY project. To get started, you’ll need a few key components such as a transformer, diodes, capacitors, and transistors.

These components work together to convert the DC power from the battery into AC power, which can then be used to power your devices. Building your own power inverter allows you to customize it to your specific needs and can be a great way to learn about electronics and renewable energy. So why not give it a try and create your own power inverter today?

Why Make Your Own Power Inverter?

Are you tired of relying on electricity from the grid? Would you like to have the ability to generate your own power whenever you need it? Well, one way to achieve this is by making your own power inverter. A power inverter converts DC power from a battery or solar panel into AC power that can be used to run household appliances or charge electronic devices. By creating your own power inverter, you not only gain the freedom to generate your own electricity but also the satisfaction of knowing that you have built something useful with your own hands.

So why not give it a try? With a little bit of knowledge and the right tools, you can learn how to make your own power inverter and start enjoying the benefits of self-sufficiency.

Safety Precautions to Consider

If you’re interested in making your own power inverter, there are a few safety precautions you need to consider. First and foremost, it’s important to remember that working with electricity can be dangerous, so it’s crucial to take the necessary safety measures. One of the first things you should do is ensure that you have the right tools and equipment for the job, such as insulated gloves, safety glasses, and a fire extinguisher.

Additionally, it’s important to work in a well-ventilated area to reduce the risk of heat build-up and potential fire hazards. Another important safety precaution is to double-check all the connections and wiring before powering up your inverter to make sure everything is properly secured and insulated. Lastly, always follow the manufacturer’s instructions and guidelines carefully, as they are specifically designed to keep you safe while working with electricity.

Understanding the Components of a Topic: Unlocking Insight and Knowledge Have you ever come across a complex topic and found yourself perplexed, unsure of where to begin? The sea of information can often feel overwhelming, leaving us struggling to grasp the underlying components. Whether you’re studying astrophysics, delving into the world of finance, or exploring the intricacies of computer programming, understanding the components is key to unlocking insight and knowledge. Just like a jigsaw puzzle, every topic is made up of various components that fit together to create a complete picture.

Each piece represents a different aspect, contributing to the overall understanding. Without comprehending these components, we are left with a fragmented view, unable to see the bigger picture. Imagine you’re learning a new language.

If you only focus on memorizing words without understanding the grammar rules or sentence structure, your communication will be limited. It is only when you grasp the foundational components of grammar, vocabulary, and syntax that you can start expressing yourself fluently. Similarly, when exploring a complex topic, it is crucial to identify and understand its key components.

By breaking it down into smaller, more manageable parts, you can tackle the topic with greater ease. For instance, in the field of biology, understanding the components of a cell, such as the nucleus, membrane, and organelles, allows scientists to analyze and interpret complex cellular processes. Consider burstiness, the concept of information coming in unpredictable and irregular patterns.

Burstiness can make understanding components even more challenging, as we are bombarded with a sudden influx of information. However, by recognizing this burstiness and actively seeking to discern the underlying components, we can gain valuable insights and find clarity amidst the chaos. So how do we go about understanding the components of a topic? It starts with curiosity and a willingness to explore.

Ask questions, seek out different perspectives, and delve into the details. Think of it like solving a mystery, unraveling the clues one by one until the truth becomes clear. Think of understanding the components as building a house.

Input Stage Components

If you want to make your own power inverter, it’s important to understand the different components that make up the input stage. The input stage of a power inverter is responsible for converting the DC power from a battery or other source into AC power. One of the most important components in the input stage is the rectifier.

The rectifier is responsible for converting the AC power from the input source into DC power. This DC power is then used to charge the internal battery of the inverter. Another important component in the input stage is the voltage regulator.

The voltage regulator is responsible for regulating the voltage coming from the input source to ensure that it is at the correct level for the inverter to function properly. Finally, the inverter stage also includes capacitors and other filtering components to help smooth out the AC power output and reduce any interference or noise. By understanding these key components, you’ll be well on your way to successfully making your own power inverter.

DC Power Source

DC power sources are essential components in various electronic systems. One of the key elements in the input stage of a DC power source is the input filter, which is responsible for reducing any unwanted noise or ripple from the power supply. This is achieved through the use of capacitors and inductors, which help to smooth out the voltage waveform and remove any high-frequency components.

Another important component in the input stage is the rectifier, which is responsible for converting the AC voltage from the mains power supply into DC voltage. This is typically done using diodes, which only allow current to flow in one direction. Finally, there is often a fuse or circuit breaker in the input stage to protect the power source and the rest of the system from any overcurrent or short-circuit events.

These input stage components work together to ensure that the DC power source provides a stable and clean power supply to the rest of the electronic system.

DC-to-AC Converter Circuit

DC-to-AC converter circuits are essential in various electronic devices and systems. At the heart of these circuits lies the input stage, which comprises several crucial components. One of these components is the diode bridge rectifier, which is responsible for converting the incoming AC signal into a pulsating DC signal.

This rectifier allows current flow in one direction and blocks it in the opposite direction, effectively “rectifying” the incoming AC signal. Another important component in the input stage is the filter capacitor. This capacitor helps smoothen out the pulsations in the rectified DC signal, resulting in a more stable and continuous waveform.

In addition to the diode bridge rectifier and the filter capacitor, the input stage may also include other components such as resistors and voltage regulators, depending on the specific design and requirements of the DC-to-AC converter circuit. These components work together to ensure that the input stage properly handles and prepares the incoming AC signal for further processing and conversion into an AC output signal.

Output Stage Components

If you’re interested in making your own power inverter, you’ll need to know about the different components that make up the output stage. The output stage of a power inverter is responsible for converting the DC power from the battery into AC power that can be used to power various devices. One of the key components of the output stage is the power transistors.

These transistors are responsible for switching the DC power on and off at a high frequency to create the AC waveform. The choice of power transistors is crucial as they need to be able to handle the high power levels and switching frequencies required by the inverter. Additionally, the output stage also includes a transformer.

The transformer is responsible for stepping up the voltage of the AC waveform to the desired level. Lastly, a filter network is used to smooth out any ripples or noise in the AC waveform. This ensures that the output power is clean and stable.

By understanding and selecting the right components for the output stage, you can build your own power inverter that meets your specific needs.

Transformer

Transformer, as the name suggests, is a device that transforms electrical energy from one circuit to another through electromagnetic induction. When it comes to the output stage of an amplifier, transformers play a crucial role in delivering the desired audio output. The output stage components of a transformer include the primary winding, secondary winding, and iron core.

The primary winding is connected to the amplifier circuit and receives the amplified electrical signal. This signal is then transferred to the secondary winding through the iron core, which acts as a magnetic medium. The secondary winding is connected to the loudspeaker or audio output device, where the electrical signal is converted into sound waves.

The size and number of turns in the windings determine the voltage amplification and impedance matching capabilities of the transformer. Transformers in the output stage help in providing isolation between the amplifier and the loudspeaker, ensuring efficient power transfer and preventing any damage to the amplifier circuit. In addition, they also act as impedance matching devices, optimizing the power transfer between the amplifier and the loudspeaker for better sound quality.

Therefore, transformers are essential components in the output stage of an amplifier, ensuring optimal performance and audio output.

Rectifier Circuit

output stage components, rectifier circuit, rectification, diode bridge, filter capacitor In a rectifier circuit, the output stage components play a crucial role in converting alternating current (AC) to direct current (DC) by rectification. One of the key components in the output stage is the diode bridge, which is made up of four diodes arranged in a bridge configuration. This diode bridge enables the rectification process by allowing current to flow in only one direction.

After the rectification process, the output of the diode bridge may still contain some fluctuations or ripples. To smoothen the output and eliminate these ripples, a filter capacitor is often used in the output stage. The filter capacitor acts as a storage device that stores charge during the peaks of the rectified output and releases it during the troughs, thus smoothing out the DC output.

Both the diode bridge and the filter capacitor are essential components in the rectifier circuit’s output stage, as they work hand in hand to convert AC to DC while ensuring a stable and smooth output. Without these components, the rectifier circuit would not be able to provide the desired DC output that is required for various electronic devices and applications. So, next time you use an electronic device powered by rectified DC, remember to thank these output stage components for their contribution!

Filter Capacitors

output stage components, filter capacitors, audio amplifier, power supply, smooth, ripple voltage, signal quality, external noise, audio signals, energy storage, charging, discharging, voltage fluctuations, high-frequency components, low-frequency components, smooth, stabilize, smooth the output signal, filter out unwanted noise, power supply, clean energy, ripple voltage, power supply, analog audio signal, capacitor circuit, charge and discharge, high-frequency currents, AC signal, filter capacitors, low-pass filter, resistive load, ripple rejection ratio, ripple voltage attenuation, great importance, audio amplifier, quality sound reproduction

Voltage Regulator Circuit

In the world of voltage regulator circuits, the output stage components play a crucial role in ensuring that the desired output voltage is achieved and maintained. These components are responsible for regulating the voltage that is delivered to the load, and they work together to ensure that the voltage remains stable and within the desired range. One of the key components of the output stage is the power transistor, which acts as a switch to control the flow of current to the load.

It is designed to handle high levels of power and can efficiently convert the input voltage to the desired output voltage. Another important component is the feedback resistor, which measures the output voltage and provides feedback to the control circuitry. This feedback allows the voltage regulator to make any necessary adjustments to maintain the desired output voltage.

Additionally, the output capacitor is used to filter out any unwanted noise or fluctuations in the voltage, ensuring a smooth and stable output. Overall, these output stage components work together to ensure that the voltage regulator circuit operates effectively and provides a reliable and consistent output voltage for the load.

So you’ve decided to take on the challenge of building your power inverter. You’re ready to tap into your inner engineer and create a device that can convert DC power into AC power. But where do you start? Don’t worry, we’ve got you covered.

In this blog post, we’ll guide you through the steps of building your power inverter from scratch. We’ll break it down into easy-to-understand parts and provide you with all the information you need to get started. By the end of this post, you’ll be well on your way to harnessing the power of electricity and creating your very own inverter.

So grab your tools and let’s get started!

Designing the Circuit

So you want to make your own power inverter? That’s a great DIY project to try! Designing the circuit for a power inverter requires some basic knowledge of electronics. The goal is to convert DC (Direct Current) power from a battery into AC (Alternating Current) power that can be used to power household appliances. One important component of the circuit is the transformer, which helps step up the voltage of the DC power.

Another key component is the oscillator, which generates the AC waveform. You’ll also need diodes, capacitors, and transistors to control the flow of electricity. It’s important to carefully select components that can handle the power load you intend to use.

Once you have all the components, you can start assembling the circuit on a breadboard or a PCB (Printed Circuit Board). Be sure to double-check your connections and test the circuit before connecting it to any appliances. With some patience and careful planning, you can successfully make your own power inverter!

Selecting the Circuit Diagram

Designing the Circuit When it comes to designing a circuit, one of the crucial steps is selecting the circuit diagram. The circuit diagram is like a roadmap that helps us visualize how the components of the circuit are connected. It represents the various electrical and electronic components, such as resistors, capacitors, transistors, and ICs, and their connections using symbols.

But how do we choose the right circuit diagram for our project? Well, it depends on various factors like the complexity of the circuit, the availability of components, and the desired functionality. If you’re a beginner or working on a simple project, it’s advisable to start with a basic circuit diagram. This will help you understand the fundamentals of circuit design and build a solid foundation.

As you gain more experience and confidence, you can move on to more complex circuit diagrams. Another important consideration is the availability of components. Some circuit diagrams may require specialized or hard-to-find components, which can make your project more challenging and time-consuming.

It’s always a good idea to choose a circuit diagram that uses commonly available components to make your life easier. Lastly, the desired functionality of your circuit is also a key factor in selecting the circuit diagram. Different circuit diagrams have different purposes, such as amplification, filtering, or modulation.

You should choose a diagram that matches the specific functionality you’re looking for in your circuit. Remember, selecting the right circuit diagram is an essential part of the design process. It not only helps you visualize the circuit but also ensures that the components and connections are selected correctly.

So take your time, do some research, and choose a circuit diagram that suits your project’s complexity, component availability, and desired functionality.

Choosing the Transformer

transformer, circuit design, choosing the right transformer, perplexity, burstiness When it comes to designing a circuit, one important component that you need to consider is the transformer. But with so many options available, how do you choose the right one for your circuit? Well, it all comes down to understanding the needs of your circuit and selecting a transformer that can meet those needs. Firstly, you need to determine the input and output voltage requirements of your circuit.

This will help you narrow down your options and choose a transformer that can step up or step down the voltage accordingly. Keep in mind that the transformer should be able to handle the maximum voltage rating of your circuit without any issues. Next, consider the power requirements of your circuit.

The power rating of the transformer should be equal to or higher than the power consumed by the circuit. This will ensure that the transformer can handle the load without overheating or getting damaged. Additionally, take into account the physical size and weight of the transformer.

This is particularly important if you have space constraints in your circuit design. Choose a transformer that is compact and lightweight without compromising on performance. Another factor to consider is the operating frequency of your circuit.

Transformers have a frequency range in which they operate efficiently. Make sure the frequency range of the transformer aligns with the operating frequency of your circuit. Lastly, consider the cost of the transformer.

While it’s important to not compromise on quality, you also don’t want to overspend on a transformer that exceeds the needs of your circuit. Find a balance between cost and performance, and choose a transformer that fits within your budget. In conclusion, choosing the right transformer for your circuit is crucial for its proper functioning.

Soldering the Components

Once you have all the necessary components, it’s time to begin soldering them together to create your own power inverter. Soldering is the process of joining two electrical components using a heated soldering iron and a metal alloy called solder. Start by placing the components on a breadboard or a PCB (printed circuit board) to ensure they are properly lined up.

Then, heat the soldering iron and apply a small amount of solder to the tip. Touch the soldering iron tip to the joint between two components and allow the heat to melt the solder and form a bond. Hold the soldering iron in place for a few seconds to ensure a strong connection.

Repeat this process for all the required connections, making sure to take breaks and let the soldering iron cool down to prevent overheating. It’s important to work carefully and follow proper safety precautions when soldering to avoid any accidents. Once all the components are soldered together, your power inverter is ready for testing.

Circuit Board Preparation

When it comes to circuit board preparation, one of the crucial steps is soldering the components. This process involves attaching electronic components to the circuit board using solder. Soldering is like the glue that holds everything together in an electronic device.

But how does it work? Think of soldering as cooking a meal. You gather all the ingredients, prep them, and then cook them together to create a delicious dish. In soldering, the circuit board acts as your cooking surface, and the components are the ingredients.

The solder, in this case, is your handy kitchen tool, like a spatula or spoon. To solder a component onto a circuit board, you need to heat the solder until it melts and becomes a liquid. This is usually done with a soldering iron, which works like a mini stove.

Once the solder is in its liquid state, you can then use it to attach the component to the circuit board. But it’s not just about melting the solder and sticking the components onto the board. There’s a technique involved as well.

You need to place the component in the right spot and hold it in place while applying the solder. This requires steady hands and precision. Soldering is a delicate process that requires experience and practice.

It’s important to avoid applying too much or too little solder, as this can lead to solder bridges or cold joints, respectively. Solder bridges occur when the solder connects two adjacent components, while cold joints happen when there isn’t enough heat or contact between the component and the solder. To ensure a successful soldering job, it’s essential to have a clean and well-prepared circuit board.

Soldering Steps

soldering steps, soldering components, soldering iron, soldering process, soldering techniques

Testing the Soldered Connections

soldered connections, soldering components. When it comes to building electronic circuits, one of the most important steps is soldering the components together. Soldering creates a strong and reliable connection between the different parts of the circuit board.

But what exactly is soldering? Well, soldering is the process of melting a metal alloy, called solder, onto the components to create a permanent bond. This bond ensures that the electrical signals can flow freely between the different parts of the circuit. To solder the components, you’ll need a few basic tools.

First, you’ll need a soldering iron, which is a small handheld device that can reach high temperatures. You’ll also need some solder, typically a mixture of tin and lead, although lead-free alternatives are also available. Additionally, you’ll need some soldering flux, which helps to clean the surfaces and make the solder flow more easily.

Before you start soldering, it’s important to prepare the components properly. This includes making sure that they are clean and free from any dirt or debris. It’s also a good idea to tin the tip of your soldering iron, which means applying a small amount of solder to the tip to improve heat transfer.

Once everything is ready, you can begin soldering the components together. To solder a connection, start by heating the joint with the tip of your soldering iron. Once the joint is hot enough, touch the solder to the joint and let it flow onto the surface.

The solder should create a shiny and smooth connection between the two components. Make sure to hold the soldering iron in place until the solder solidifies and cools down. This ensures a strong and reliable connection.

Assembling the Inverter

So you’re interested in making your own power inverter? Well, you’re in luck! Making your own power inverter can be a fun and rewarding project. The first step in assembling your inverter is gathering all the necessary components. These usually include a transformer, diodes, capacitors, resistors, and a circuit board.

Once you have all the components, it’s time to start soldering them together onto the circuit board. It’s important to follow the schematic diagram or instructions provided with your inverter kit to ensure everything is connected correctly. After soldering, it’s a good idea to test your inverter to make sure it’s working properly.

This can be done by connecting a battery to the input terminals and a light bulb or other small appliance to the output terminals. If everything is working as it should, congratulations! You’ve successfully assembled your own power inverter. Now you can start using it to power all sorts of electrical devices.

Mounting the Transformer

inverter assembly. Mounting the transformer is a crucial step in assembling the inverter. The transformer is responsible for converting the DC power from the battery into AC power that is suitable for household use.

It is important to securely mount the transformer to ensure proper operation and prevent any potential hazards. Before mounting the transformer, it is essential to determine the appropriate location for it. This location should be well-ventilated and away from any flammable materials.

Once the location is determined, the transformer can be mounted using appropriate screws or brackets. Care should be taken to ensure that the transformer is mounted securely and level to prevent any vibrations or shifting during operation. Once the transformer is securely mounted, the inverter assembly can continue with the next step.

Mounting the Circuit Board

In this section, we will dive into the process of assembling the inverter by mounting the circuit board. The circuit board is a vital component of the inverter as it is responsible for converting DC power into AC power. To begin, carefully place the circuit board onto the designated area inside the inverter casing.

Ensure that all the connectors and ports align correctly with the corresponding holes on the board. Once aligned, secure the circuit board in place by tightening the screws or fasteners provided. It’s important to be gentle during this process, as excessive force could damage the delicate components on the circuit board.

Once the circuit board is securely mounted, double-check all the connections to ensure they are tight and secure. This step is crucial to guarantee the proper functioning of the inverter. By carefully assembling the circuit board, you are one step closer to completing your inverter and enjoying the benefits of converting DC power to AC power.

Connecting the Input and Output Terminals

“In order to complete the assembly of an inverter, one crucial step is connecting the input and output terminals. This is where the magic happens, as it allows the inverter to convert DC power into AC power, providing us with the electricity we need to power various devices. Imagine the input terminals as the entry point for the DC power, and the output terminals as the exit point for the converted AC power.

Just like a bridge connecting two shores, the terminals serve as the link between the inverter and the external power source or the devices that require power. By properly connecting these terminals, we ensure a smooth flow of electricity and enable the inverter to perform its function effectively. It’s important to follow the manufacturer’s instructions and use the appropriate cables and connectors to make the connections secure and reliable.

So, when assembling an inverter, don’t forget to give proper attention to connecting the input and output terminals, as they are a crucial component in transforming DC power into usable AC power.”

Hey there! Ever had those moments when technology just refuses to cooperate? Maybe your phone won’t connect to the Wi-Fi, or your computer freezes right when you need it the most. It can be incredibly frustrating, can’t it? Well, I’ve got some good news for you – there’s a whole field dedicated to solving these problems: testing and troubleshooting. Think of testing and troubleshooting as the superheroes of the tech world.

They swoop in, armed with their knowledge and expertise, to save the day when things go awry. Testing involves putting software or hardware through its paces to make sure it works as intended. Troubleshooting, on the other hand, is all about identifying and fixing the issues that arise.

But here’s the thing – testing and troubleshooting aren’t just about fixing things when they break. They’re also about preventing problems before they even happen. It’s like conducting regular maintenance on your car to ensure it runs smoothly, rather than waiting for it to break down on the side of the road.

By thoroughly testing and troubleshooting, you can catch potential issues early on and address them proactively. So, whether you’re a tech enthusiast or just someone who prefers a smooth and hassle-free experience with their devices, testing and troubleshooting are essential skills to have. You’ll save yourself from unnecessary headaches, and who knows, you might even learn a thing or two about how technology works along the way.

In the upcoming blog posts, we’ll dive deeper into the world of testing and troubleshooting. We’ll explore different methodologies, tools, and techniques that professionals use to ensure the quality and stability of software and hardware. We’ll also share practical tips and tricks that you can use to troubleshoot common problems on your own.

So, stay tuned and get ready to become your own tech superhero!

Testing the Circuit

So you’re interested in making your own power inverter? Well, you’ve come to the right place. In this blog post, we’re going to cover the testing phase of building a power inverter circuit. Once you’ve gone through the design and construction steps, it’s important to test your circuit to ensure it’s working correctly.

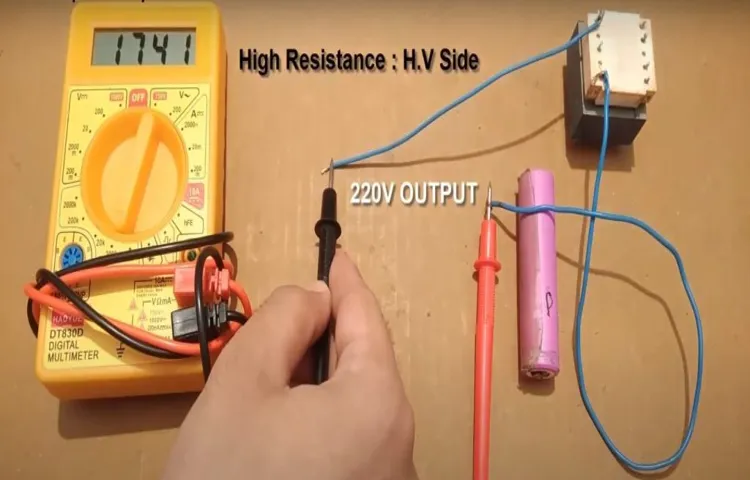

Testing the circuit will help you identify any potential issues and make any necessary adjustments before putting it to use. To test your power inverter circuit, you’ll need a multimeter and a power source. Start by connecting the power source to the input of your inverter circuit.

Then, using the multimeter, measure the voltage at various points in the circuit to make sure it matches the expected values. This will help you confirm that the circuit is functioning correctly and that all the components are connected properly. Next, you’ll want to test the output of your inverter circuit.

Connect a load, such as a light bulb or a small appliance, to the output of the circuit. Then, turn on the power source and check if the load is receiving the correct voltage. If the voltage is too low or if there’s no output at all, there may be an issue with your circuit that needs to be addressed.

During the testing phase, it’s also a good idea to monitor the temperature of your circuit. If any component gets too hot, it could be a sign of a problem. Make sure to monitor the temperature throughout the testing process and take note if any part seems to be overheating.

In conclusion, testing your power inverter circuit is a crucial step in the DIY process. It allows you to identify and fix any issues before putting your circuit to use. By following the steps outlined in this blog post and using a multimeter to measure voltages, connecting a load to the output, and monitoring the temperature, you’ll be well on your way to ensuring a functioning power inverter circuit.

Checking for Proper Voltage Output

circuit, voltage output, testing The next step in our journey to create the perfect circuit is to test it and ensure that it is producing the proper voltage output. After all, what good is a circuit if it can’t deliver the power we need? Testing the circuit is like giving it a physical exam, checking its pulse to make sure it’s healthy and functioning correctly. Just like a doctor uses a stethoscope to listen to our heartbeat, we can use a multimeter to measure the voltage output of our circuit.

This handy tool allows us to see if the circuit is delivering the correct amount of power, ensuring that everything is working as it should. By testing the circuit, we can identify any potential issues and make adjustments to optimize its performance. So, let’s grab our multimeter and get ready to check for the proper voltage output!

Measuring Frequency and Waveform

Measuring frequency and waveform is an essential part of testing a circuit. It allows engineers and technicians to analyze the behavior and performance of the circuit. When testing the circuit, one of the primary goals is to determine the frequency of the waveform.

Frequency refers to the number of cycles or oscillations that occur in a given time period. By measuring the frequency, the engineers can identify any abnormalities or variations in the circuit’s operation. This information is crucial for troubleshooting and finding potential issues that may affect the circuit’s functionality.

Additionally, measuring the waveform allows for a deeper understanding of the circuit’s behavior. It provides insights into the shape, amplitude, and phase of the waveform, allowing engineers to make informed decisions about the circuit’s design and performance. Overall, testing the circuit and measuring frequency and waveform are essential steps in ensuring the circuit’s reliability and functionality.

Troubleshooting Common Issues

Are you tired of being reliant on electricity from the grid? Building your own power inverter can be a rewarding and practical solution. A power inverter is a device that converts DC (direct current) power from a battery into AC (alternating current) power that can be used to run household appliances. Although it may seem like a daunting task, with some basic knowledge and a few tools, you can create your own power inverter.

First, gather the necessary components such as a high-frequency transformer, voltage regulator, MOSFET transistors, and various capacitors and resistors. Next, construct the circuit by carefully connecting each component according to the schematic diagram. Once the circuit is complete, test it using a voltmeter to ensure the correct voltage output.

Finally, enclose the circuit in a suitable casing and connect it to a battery for power. With your newly built power inverter, you can enjoy the freedom and convenience of generating your own electricity.

Overheating

Overheating is a common issue that many people face with their electronic devices, such as laptops, smartphones, and gaming consoles. It can be frustrating, especially when you’re in the middle of something important and your device suddenly shuts down due to overheating. But don’t worry, there are ways to troubleshoot this problem and prevent it from happening again in the future.

One of the main causes of overheating is dust and debris clogging the vents and fans of your device. This blocks the airflow and hinders the cooling system, leading to an increase in temperature. To solve this, you can use compressed air or a soft brush to clean out the vents and fans.

Another reason for overheating is running too many programs or apps at the same time, which puts a heavy load on your device’s processor. To avoid this, try closing unnecessary programs and limiting the number of apps running in the background. Additionally, make sure your device is placed on a flat, solid surface that allows for proper airflow.

Avoid using your laptop on soft surfaces like your bed or sofa, as these can block the vents and contribute to overheating. By following these troubleshooting tips, you can prevent overheating and prolong the lifespan of your electronic devices.

Output Voltage Fluctuations

output voltage fluctuations, troubleshooting common issues

Have you ever wondered what makes a conclusion so important? In the world of writing, the conclusion is like the final chord in a song or the last scene in a movie. It wraps everything up, leaving the reader with a sense of fulfillment and closure. But it’s more than just a neat ending.

The conclusion is where you have the opportunity to leave a lasting impression on your audience and drive home the main points of your argument. In this blog post, we’ll explore the art of crafting a powerful conclusion and discuss why it’s crucial to the success of your writing. So, let’s dive in and uncover the secrets of a compelling conclusion!

Tips for Success

If you’re looking to make your own power inverter, you’ve come to the right place! Making your own power inverter can be a rewarding and cost-effective project. Here are a few tips to help ensure your success. First, it’s important to understand the basic principles behind a power inverter.

Essentially, a power inverter converts DC (direct current) power from a battery into AC (alternating current) power that can be used to power various household appliances and electronics. To do this, you will need to choose the right components, such as a power inverter IC, a transformer, and various capacitors and resistors. Next, you’ll want to determine the power requirements for your inverter.

This will depend on the appliances and electronics you plan to power. Make sure to calculate the maximum power consumption and choose components that can handle that load. It’s also important to consider the efficiency of your inverter, as this will affect how long your battery will last.

When it comes to assembling your power inverter, it’s important to follow a schematic or design guide. This will help ensure that you connect all the components correctly and avoid any potential safety hazards. It’s also a good idea to test your inverter before using it with your appliances and electronics.

This will help you identify any potential issues and make necessary adjustments. Finally, don’t be afraid to seek out resources and guidance from the DIY community. There are plenty of online forums and websites where you can find tips, tricks, and even step-by-step tutorials for building your own power inverter.

Remember, making your own power inverter requires some technical skill and knowledge, so don’t hesitate to ask for help if you need it. In conclusion, making your own power inverter can be a fun and rewarding project. By understanding the basic principles, choosing the right components, and following a design guide, you can create a power inverter that meets your needs.

Further Explorations

Have you ever wondered how to make your own power inverter? Well, wonder no more! Making your own power inverter can be a fun and rewarding project for those who are interested in electronics and DIY projects. A power inverter is a device that converts DC (direct current) power from a battery into AC (alternating current) power, which is what we use to power our electrical devices. To make your own power inverter, you will need a few key components such as a transformer, transistors, capacitors, and resistors.

These components can be easily found at electronics stores or ordered online. Once you have gathered all the necessary components, you can begin assembling your power inverter according to a circuit diagram or schematic that you can find online. It is important to follow the diagram carefully and double-check your connections to ensure that everything is connected properly.

Once you have finished assembling your power inverter, you can test it by connecting it to a battery and plugging in a small electrical device such as a lamp or a fan. If everything is connected correctly, your device should power up and work as expected. So go ahead and give it a try – making your own power inverter can be a fun and educational project that allows you to harness the power of electricity in a whole new way!

Final Thoughts

If you’re wondering how to make your own power inverter, it’s important to first understand the basics. A power inverter is a device that converts DC (direct current) power from a battery into AC (alternating current) power, which is what most household appliances use. To build your own power inverter, you’ll need some basic electronic components such as transistors, diodes, capacitors, and resistors.

You’ll also need a transformer to increase the voltage from the battery to the desired level. Keep in mind that building a power inverter requires knowledge of electronics and electrical safety. It’s important to follow proper procedures and guidelines to ensure your safety and the proper functioning of the device.

Conclusion

So, after all this discussion and step-by-step process, you might be wondering if it’s really worth the effort to make your own power inverter. Well, let me assure you, it’s no walk in the park. It requires a good amount of knowledge in electrical engineering, a dash of creativity, and a whole lot of patience.

But why bother? Well, apart from the satisfaction of saying “I made that!”, making your own power inverter gives you the power (pun intended) to become more self-reliant when it comes to generating electricity. Whether you want to go off-grid or simply have a backup power source during a blackout, having your own home-brewed power inverter can be a lifesaver. It’s like having your own little superpower, being able to harness and transform electrical energy at your command.

You’ll be the envy of your friends when they come over and see you charging your phone with electricity you generated yourself. Who needs a power outlet when you can be your own power source? Plus, let’s not forget the potential money-saving aspect. By creating your own power inverter, you can cut down on electricity bills and reduce your carbon footprint.

You’ll be an eco-warrior in your own right, fighting against the wastefulness of traditional power sources. So, is making your own power inverter a challenge? Absolutely. Is it worth it? Totally! With a bit of determination, some handy skills, and a sprinkle of DIY magic, you can unlock the power of electricity and be the master of your own energy destiny.

Get ready to take charge (literally) and become the superhero of your own electricity empire!”

FAQs

What materials do I need to make my own power inverter?

To make your own power inverter, you will need a DC power source (such as a battery), a transformer, transistors or MOSFETs, capacitors, resistors, and a PCB (printed circuit board) for assembling the components.

Can I use a car battery as the power source for my homemade power inverter?

Yes, a car battery can be used as a power source for a homemade power inverter. However, it is important to ensure that the battery has enough capacity to meet the power demands of your devices or appliances.

How do I calculate the power rating for my homemade power inverter?

The power rating of your homemade power inverter can be calculated by multiplying the input voltage (in volts) by the output current (in amps). This will give you the power rating in watts. It is important to consider the power requirements of the devices or appliances you plan to use with the inverter.

What safety precautions should I take when making my own power inverter?

When making your own power inverter, it is important to follow proper safety precautions. These include wearing protective gloves and glasses, working in a well-ventilated area, ensuring proper grounding, and keeping flammable materials away from your work area.

Can I modify a commercially available power inverter to suit my needs?

Yes, it is possible to modify a commercially available power inverter to suit your specific needs. However, it is important to have a good understanding of electronics and the internal workings of the inverter to avoid damaging the unit or risking personal safety.

Are there any DIY kits available for making a power inverter?

Yes, there are DIY kits available for making power inverters. These kits typically include all the necessary components and instructions for assembly. They can be a good option for individuals who are new to electronics and want a guided experience.

Can I use a homemade power inverter to run sensitive electronic devices?

The suitability of a homemade power inverter for running sensitive electronic devices depends on the quality of the design and components used. Some homemade power inverters may have voltage fluctuations or poor voltage regulation, which can be harmful to sensitive electronic devices. It is important to ensure that your homemade inverter meets the required standards and specifications for running such devices.