Have you noticed a hole in your tonneau cover? Don’t panic! Although it may seem like a major setback, repairing a hole in your tonneau cover is actually a relatively simple process that you can easily do yourself. Whether the hole is small or large, fixing it is essential to maintain the integrity of your tonneau cover and protect your cargo from the elements. In this blog post, I will walk you through the steps to repair a hole in your tonneau cover, saving you time and money in the process.

So, grab your tools and let’s get started!

Table of Contents

Introduction

Are you frustrated by an annoying hole in your tonneau cover? Don’t worry, because fixing it is easier than you think! Tonneau covers are designed to protect your truck bed from the elements, but they can sometimes develop punctures or tears. Thankfully, repairing a hole in a tonneau cover is a simple task that you can do yourself. Whether you have a vinyl, fabric, or aluminum cover, the process is basically the same.

In this blog post, we will guide you through the steps to repair a hole in your tonneau cover and get it looking good as new. So grab your tools and let’s get started!

Discuss the purpose of a tonneau cover and its importance in protecting truck beds

tonneau cover, protecting truck beds Introduction: If you own a truck, you know how versatile and useful it can be. Whether you use it for work or play, having a truck bed that is protected and secure is essential. This is where a tonneau cover comes in.

A tonneau cover is a type of covering that fits over the bed of a truck, providing protection and security. It is made from various materials, such as vinyl or aluminum, and can be installed easily. But what is the purpose of a tonneau cover, and why is it important in protecting truck beds? In this article, we will delve into the reasons why a tonneau cover is an essential accessory for any truck owner.

Identify the Type of Hole

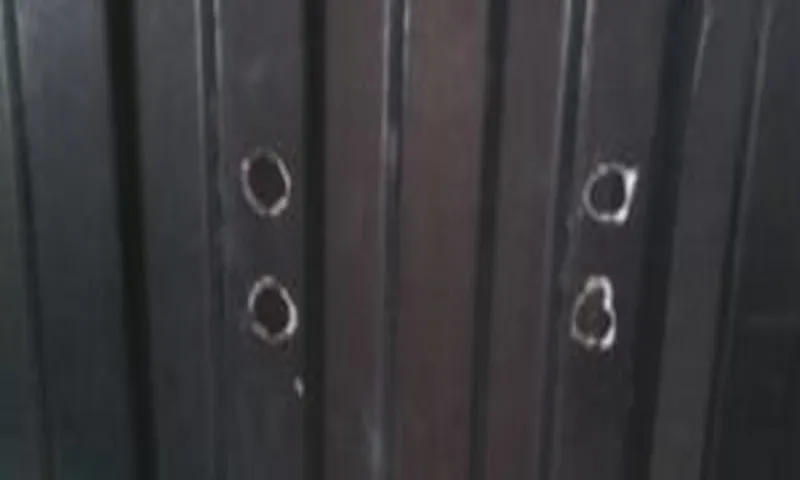

Have you noticed a hole in your tonneau cover and wondering how to repair it? Don’t worry, it’s a common issue that many truck owners face. The first step is to identify the type of hole you’re dealing with. Is it a small puncture or tear? Or is it a larger hole that needs more extensive repair? Small punctures or tears can often be fixed with a simple patch.

There are adhesive patches available specifically designed for tonneau covers. These patches are typically made of a durable, waterproof material that can be easily applied over the hole. Just make sure to clean the area thoroughly before applying the patch to ensure a strong bond.

For larger holes, you may need to consider a more involved repair. In some cases, you may need to sew the hole closed using a heavy-duty thread and needle. This method is best for tears or larger punctures where a patch may not be sufficient.

Be sure to reinforce the area around the hole with additional stitching to prevent further damage. If you’re not confident in your ability to repair the hole yourself, it’s always a good idea to consult a professional. They will have the expertise and tools necessary to properly fix the hole and ensure it doesn’t become a larger issue down the road.

Remember, the key to repairing a hole in a tonneau cover is to act quickly. Small holes can quickly turn into larger ones if left untreated, so don’t delay in addressing the issue. With the right materials and a bit of patience, you can have your tonneau cover looking good as new in no time.

Explain the different types of holes (small punctures, tears, large gashes)

One of the first steps in fixing a hole is identifying the type of hole you’re dealing with. Holes can come in various forms, from small punctures to tears and even large gashes. Small punctures are typically tiny holes created by sharp objects like nails or needles.

These holes are usually easy to fix with a patch or glue. Tears, on the other hand, occur when a larger object or force causes the material to rip. This type of hole may require more extensive repair, such as sewing or using a patch.

Lastly, we have large gashes, which are significant tears or cuts in the material. These holes often require specialized repair techniques and may need to be sewn or reinforced with additional materials. By correctly identifying the type of hole, you can determine the best approach for fixing it and ensure a successful repair.

Advise readers to inspect the hole carefully to determine the best repair method

When it comes to repairing a hole in a wall, it’s important to first identify the type of hole you’re dealing with. This will help you determine the best repair method and ensure a successful outcome. There are several types of holes that can occur in walls, including small nail holes, larger screw holes, and even holes caused by accidents or damage.

Each type of hole may require a different approach to repair it effectively. By carefully inspecting the hole and considering its size, depth, and location, you can determine which repair method will work best. Whether it’s filling in a small hole with spackle or patching a larger hole with a piece of drywall, taking the time to identify the type of hole will save you time and effort in the long run.

So before you begin any repairs, make sure to give your wall a thorough inspection to ensure you’re using the right method for the job.

Materials Needed

If you have a tonneau cover with a hole in it, don’t worry! You can easily repair it yourself with just a few materials. First, you’ll need a repair kit specifically designed for tonneau covers. These kits usually include a patch and adhesive that is strong enough to withstand weather and hold up against everyday wear and tear.

You’ll also need a clean cloth or sponge to clean the area around the hole before applying the patch. Once the area is clean, follow the instructions on the repair kit to apply the patch. Make sure to press it firmly onto the cover to ensure a secure bond.

After the patch is applied, give it time to dry and set before using your tonneau cover again. With these simple materials, you can easily repair a hole in your tonneau cover and prolong its lifespan.

List the materials required for patching the hole (patch kit, adhesive, scissors)

If you’re faced with a hole in your clothing or fabric, don’t worry! Patching it up is easier than you think. To get started, there are a few materials you’ll need. First, you’ll need a patch kit.

This typically includes patches in various sizes and colors, allowing you to choose one that matches your fabric perfectly. Next, you’ll need adhesive. The adhesive is used to secure the patch to the fabric and can be found in most sewing or craft stores.

You’ll also need a pair of scissors to trim the patch to the desired size and shape. With these materials in hand, you’ll be well-equipped to tackle any hole in your garments or fabric. So, don’t let a little hole ruin your day – patch it up and get back to looking your best!

Explain the importance of using high-quality materials for a durable and long-lasting repair

Using high-quality materials for a durable and long-lasting repair is of utmost importance. When it comes to fixing or repairing something, using low-quality materials may seem like a cost-effective solution initially, but it can lead to more problems down the line. High-quality materials not only ensure a sturdy repair but also offer longevity and durability.

One of the main advantages of using high-quality materials is that they are designed to withstand wear and tear. Whether you are repairing a vehicle, a piece of furniture, or a household appliance, using materials that are specifically made for that purpose ensures that the repair will stand the test of time. Low-quality materials, on the other hand, may deteriorate quickly, leading to the need for frequent repairs or replacements.

Another reason why high-quality materials are essential is that they provide better performance. Whether it is a fastener, adhesive, or any other component, using high-quality materials ensures that the repaired item will function optimally. This is particularly important for critical repairs where safety is a concern.

For example, using low-quality materials to fix a braking system in a car can compromise the vehicle’s safety and put both the driver and passengers at risk. Using high-quality materials can also save you time and money in the long run. While it may be tempting to opt for cheaper alternatives, they often require more frequent repairs or replacements.

This can result in additional expenses and wasted time. On the other hand, investing in high-quality materials may cost more upfront but can save you money in the long term as you won’t need to constantly fix or replace the repaired item. In conclusion, using high-quality materials for a durable and long-lasting repair is crucial.

From withstanding wear and tear to providing better performance and saving time and money, high-quality materials ensure a sturdy repair that will stand the test of time. So, the next time you undertake a repair project, make sure to invest in high-quality materials to ensure a job well done.

Small Punctures

If you discover a small puncture in your tonneau cover, no need to worry! Repairing a hole in a tonneau cover is a relatively simple process. First, you will want to clean the area surrounding the hole with a mild soap and water solution. Once clean, dry the area thoroughly.

Next, apply a patch over the hole using a vinyl repair kit. These kits typically include adhesive patches that can be cut to the desired size. Simply peel off the backing, place the patch over the hole, and press firmly to ensure proper adhesion.

Once the patch is in place, allow it to dry completely before using your tonneau cover again. This quick fix will have your tonneau cover looking as good as new and ready to protect your truck bed from the elements once again.

Describe the process of repairing small punctures using a patch kit

small punctures, repair, patch kit Have you ever been on a bike ride and suddenly felt the tell-tale sign of a small puncture? It’s frustrating, isn’t it? But fear not, because repairing small punctures is actually quite simple with the help of a patch kit. These kits are designed to provide all the necessary tools and materials to fix your puncture quickly and effectively. First, you’ll need to locate the puncture on your tire.

This can be done by inflating your tire and listening for a hissing sound, or by applying soapy water to the tire and looking for bubbles. Once you’ve found the puncture, use a tire lever or your fingers to remove the tire from the rim. Next, you’ll need to clean the area around the puncture.

This is an important step, as it ensures that the patch will adhere properly. Use a piece of sandpaper or a metal file to roughen up the surface. Then, use a clean cloth to wipe away any dirt or debris.

Now it’s time to apply the patch. Take a patch from the kit and peel off the protective backing, revealing the sticky side. Place the patch over the puncture, making sure to press it firmly onto the tire.

Use your fingers to smooth out any air bubbles or wrinkles. Once the patch is applied, it’s time to reassemble the tire. Push the tire back onto the rim, starting at one side and working your way around.

Use your hands or a tire lever to guide the tire back into place. Finally, inflate your tire to the recommended pressure and give it a spin to make sure it’s holding air properly. If there are no leaks or issues, you’re good to go! Repairing small punctures using a patch kit is a handy skill to have, as it allows you to quickly and easily fix your own flat tires.

Provide step-by-step instructions with accompanying images

small punctures, step-by-step instructions, accompanying images Small punctures can happen to anyone at any time, whether it’s a pinprick from a sewing needle or a tiny hole in your favorite t-shirt. But don’t worry, fixing small punctures is easier than you might think. With some simple steps and a few basic materials, you can mend those tiny holes and get back to wearing your favorite clothes in no time.

First, gather your materials. You’ll need a needle, some thread that matches the color of your garment, and a thimble if you have one. It’s also helpful to have a pin or safety pin to hold the fabric in place while you work.

Next, identify the puncture. Look closely at the hole and determine if any threads are loose or if there are any frayed edges. If there are, gently trim them with a pair of small scissors to create a clean edge.

Thread your needle. Cut a length of thread that is about twice as long as the puncture, and thread it through the eye of the needle. Tie a knot at the end of the thread, leaving a small tail.

Now you’re ready to stitch. Start by inserting the needle through the fabric from the inside, near the edge of the puncture. Hold the tail of the thread against the fabric to secure it.

Then, bring the needle back through the fabric about a centimeter away, creating a small straight stitch. Continue stitching in this manner, moving along the edge of the hole. Make sure to keep your stitches small and close together for a neat and secure repair.

Tears

Have you noticed a tear in your tonneau cover? It can be frustrating to have a hole in your cover, as it can lead to water and debris getting inside your truck bed. But fear not, repairing a hole in a tonneau cover is not as difficult as it may seem. There are a few options available to repair the tear, depending on the size and severity of the damage.

If the hole is small and not too deep, you can try using a clear vinyl repair kit. These kits usually come with adhesive and a patch that you can stick over the tear to seal it. Another option is to use a tonneau cover repair tape, which is a heavy-duty adhesive tape specifically designed for repairing tears in truck covers.

Simply cut a piece of the tape to the size of the hole and apply it over the tear. It’s important to make sure the cover is clean and dry before applying the adhesive. If the tear is larger or more severe, you may need to consider replacing the tonneau cover.

However, before resorting to this option, it’s worth trying the repair methods mentioned above. With a little bit of patience and effort, you can easily fix a hole in your tonneau cover and keep your truck bed protected.

Explain how to repair tears using adhesive and patch

When it comes to tears in clothing, adhesive and patch can be lifesavers. Repairing tears with these materials is a relatively easy process that can extend the life of your favorite garments. First, gather your supplies: fabric adhesive and fabric patches that match the color and texture of your clothing.

Start by cleaning the area around the tear to ensure a smooth and even repair. Apply a small amount of fabric adhesive to the edges of the tear and press them together. Let the adhesive dry completely, following the instructions on the adhesive packaging.

Once the adhesive is dry, cut a fabric patch slightly larger than the tear. Place the patch over the tear and firmly press it down, ensuring it adheres well. If desired, you can also stitch around the edges of the patch for added reinforcement.

With a little bit of time and effort, you can easily repair tears in your clothing using adhesive and patch, saving you money and keeping your wardrobe intact.

Include tips on preparing the tear, applying the adhesive, and securing the patch

When it comes to fixing tears in various materials, such as clothing or upholstery, it’s important to properly prepare the tear, apply the adhesive, and secure the patch. So, let’s dive into each step in more detail. First, you’ll want to prepare the tear.

This involves cleaning the area around the tear to ensure the adhesive will bond properly. Use a gentle fabric or surface cleaner, if applicable, and carefully remove any loose threads or debris. Next, consider the size and shape of the tear.

If it’s a larger tear, you may need to trim any frayed edges to create a clean line and facilitate a better bond with the adhesive. Once the tear is prepared, it’s time to apply the adhesive. There are different types of adhesives available depending on the material you’re working with.

For fabric tears, fabric glue or a strong fabric adhesive is recommended. Apply a small amount of adhesive to both sides of the tear, making sure to spread it evenly and cover the entire area. Be careful not to use too much adhesive, as it may seep through the fabric or cause it to become stiff.

After applying the adhesive, you’ll want to secure the patch. A patch can be a piece of matching fabric or a pre-made adhesive patch that is specifically designed for repairing tears. Place the patch over the tear, aligning it as closely as possible.

Gently press down on the patch to secure it in place, ensuring all edges are firmly attached. To provide additional reinforcement and prevent the tear from reopening, you can also use a needle and thread to sew along the edges of the patch. This will create a stronger bond and add stability to the repair.

Large Gashes

So, you have a tonneau cover for your truck, but unfortunately, a large gash or hole has appeared. Don’t worry, repairing it is actually quite doable. First, you’ll need to assess the damage and determine the size of the hole.

If it’s a small hole, you can use a vinyl repair kit, which typically includes adhesive and a patch. Simply clean the area around the hole, apply the adhesive, and cover it with the patch. Press firmly to ensure a tight bond.

If the hole is larger, you may need to consider a more extensive repair. In this case, you can use a combination of adhesive and a vinyl repair patch. Clean the area, apply the adhesive, and then place the patch over the hole.

Again, press firmly to ensure a secure bond. It’s important to note that these repairs may not be completely invisible, but they will help to prevent further damage and ensure the functionality of your tonneau cover.

Outline the steps for repairing large gashes using a combination of adhesive and patch

adhesive, patch, repairing large gashes. Large gashes on surfaces like walls, floors, or furniture can be quite unsightly and pose a risk of further damage if left untreated. Fortunately, there is an effective method for repairing these large gashes using a combination of adhesive and a patch.

The first step in the process is to clean the gash thoroughly to ensure the best possible adhesion. This can be done using a mild detergent and water, or in some cases, a gentle solvent may be required to remove any grease or grime. Once the gash is clean, the next step is to apply the adhesive.

There are various types of adhesive available, so it’s important to choose one that is suitable for the surface and the size of the gash. A strong, durable adhesive is best for large gashes. Apply the adhesive evenly to the entire area where the patch will be placed, ensuring good coverage.

Next, place the patch over the adhesive, pressing it firmly into place. The patch can be made from a variety of materials, such as fabric, vinyl, or even a piece of the same material as the surface being repaired. Make sure the patch completely covers the gash and overlaps onto the surrounding area.

This will help to provide extra reinforcement. After the patch is in place, it’s important to allow the adhesive to cure fully. Follow the manufacturer’s instructions for the recommended curing time.

Once the adhesive has cured, check the patch for any loose edges or areas that may need additional adhesive. If necessary, apply more adhesive and press the patch firmly into place. Finally, once the patch is secure, it’s important to paint or finish the repaired area to match the surrounding surface.

Suggest reinforcing the repair with additional patches for added strength

If you find yourself faced with a large gash in your project or repair job, don’t panic! There are steps you can take to reinforce the repair and ensure that it holds up over time. One suggestion for adding strength to the repair is to apply additional patches. These patches can be made from the same material as the original repair or from a slightly stronger material.

By adding these patches, you are essentially creating a double layer of protection, which can help prevent further damage or tearing. Think of it like adding an extra layer of armor to your repair job. It’s like putting on a second layer of skin to protect a wound.

By reinforcing the repair with additional patches, you are giving it added strength and durability. So the next time you encounter a large gash, don’t be afraid to patch it up with some extra reinforcements. Your repair job will thank you!

Maintenance Tips

Have you ever noticed a hole in your tonneau cover and wondered how to repair it? Don’t worry, we’ve got you covered! Repairing a hole in a tonneau cover is a relatively simple task that you can do yourself. First, you’ll need to assess the size and severity of the hole. If it’s a small hole, you can use a patch kit specifically designed for tonneau covers.

These kits usually include adhesive-backed patches that you can apply directly to the hole. For larger holes, you may need to replace the entire section of the cover. This can be done by ordering a replacement section from the manufacturer or using a patch kit that includes fabric and adhesive.

Regardless of the size of the hole, it’s important to clean and dry the affected area before making any repairs. This will ensure that the adhesive sticks properly and provides a strong, long-lasting seal. With a little bit of time and effort, you can easily repair a hole in your tonneau cover and keep it looking and functioning as good as new.

Offer tips on preventing future holes in tonneau covers

tonneau cover maintenance, preventing holes in tonneau covers, tips for maintaining tonneau covers

Recommend regular inspections and prompt repairs to avoid further damage

Regular inspections and prompt repairs are essential to maintaining the quality and longevity of any property. Ignoring minor issues can lead to more significant damage and expensive repairs down the line. By conducting regular inspections, property owners can identify potential problems, such as leaks, cracks, or structural issues, early on.

Prompt repairs can then be carried out to prevent further damage and maintain the integrity of the property. Just like how we go to the doctor for regular check-ups to catch any health issues early, regular property inspections serve as a preventative measure to avoid costly repairs in the future. It’s always better to catch a leak when it’s just a small drip instead of waiting until it has turned into a flooded basement.

So, take the time to inspect your property regularly and don’t neglect any minor damages that may arise. It’s a small investment of time and money now that can save you from a major headache and financial burden in the future.

Conclusion

In conclusion, repairing a hole in a tonneau cover is like mending a broken heart – it requires precision, creativity, and a little bit of ingenuity. Just like in the game of love, we often find ourselves caught in unexpected situations that leave us with visible scars. But fear not, my brave DIY warriors, for with the right tools and techniques, we can stitch back together the fabric of our tonneau covers and restore them to their former glory.

Whether it be a puncture from a mischievous branch or a tear caused by a sharp object, we must approach this challenge with determination and a sense of adventure. So grab your needle and thread, channel your inner MacGyver, and embark on this quest to heal the wounds of your beloved tonneau cover. Remember, repairing a hole is not just about functionality, it’s about asserting our dominance over fate and showing that even in the face of adversity, we can conquer anything that threatens to unravel our happiness.

So go forth, fellow repair enthusiasts, and let your creativity soar as you weave together the threads of resilience, proving once and for all that holes don’t stand a chance against our mighty repair skills!”

Summarize the importance of repairing holes in tonneau covers to maintain their functionality

repair holes in tonneau covers, maintain functionality, maintenance tips, importance When it comes to tonneau covers, one of the most important aspects of maintenance is ensuring that any holes or tears are repaired promptly. You may be wondering, why is it so essential to mend these small imperfections? Well, let me break it down for you. Tonneau covers, also known as truck bed covers, provide a barrier between your truck bed and the outside elements.

They are designed to keep your cargo safe from weather conditions such as rain, snow, and harmful UV rays. However, even a small hole or tear in the cover can compromise its functionality and put your cargo at risk. Imagine you’re driving during a rainy day.

Your tonneau cover has a small hole that you haven’t repaired yet. As you drive, rainwater seeps through that hole and into your truck bed, exposing your cargo to the wet conditions. Not only can this damage your goods, but it can also lead to mold and mildew growth, which can be difficult to remove and cause unwanted odors.

Now, let’s talk about the sun. If your tonneau cover has a tear, UV rays can penetrate through it and fade the color of your truck bed and any items you may have stored there. Nobody wants their truck bed to look worn out and faded, right? Besides protecting your cargo, repairing holes in tonneau covers maintains their overall functionality.

A cover with small holes or tears can create flapping or fluttering movements while you are driving. This can not only be annoying but also create extra drag, which affects your fuel efficiency. Imagine driving on the highway with your tonneau cover flapping in the wind like a flag on a windy day – not only would it be distracting, but it could also result in increased fuel consumption.

Repairing those holes ensures a snug fit and reduces any unnecessary movement, resulting in a smoother and more enjoyable driving experience. So, what can you do to maintain your tonneau cover’s functionality? First and foremost, inspect your cover regularly for any signs of damage, and if you notice any holes or tears, take immediate action to repair them. This could involve using patch kits, adhesive tapes, or even seeking professional assistance if needed.

Encourage readers to follow the provided instructions for a successful repair

When it comes to repairing something, following the provided instructions is crucial for a successful outcome. Whether you’re fixing a leaky faucet or replacing a broken window pane, taking the time to read and understand the instructions can save you a lot of frustration in the long run. These instructions are often created by experts who know the best practices for the repair process.

They will provide you with step-by-step guidelines, safety precautions, and tips to make the repair go smoothly. Even if you’re an experienced DIY-er, it’s important not to overlook the instructions as each repair may have unique requirements. So, before you dive into a repair project, make sure you take the time to carefully read and follow the instructions provided.

FAQs

How can I repair a hole in my tonneau cover?

To repair a hole in your tonneau cover, you can start by cleaning the damaged area and removing any loose threads or debris. Then, you can apply a patch or repair tape specifically designed for tonneau covers. Make sure to follow the manufacturer’s instructions for the best results. Additionally, if the hole is large or the damage is extensive, you may need to consider replacing the entire cover.

Can I use a DIY solution to fix a hole in my tonneau cover?

While there are DIY solutions available to fix a hole in a tonneau cover, it’s important to note that these may not provide a long-lasting or secure repair. If you’re looking for a temporary fix, you can use materials like duct tape or adhesive patches. However, for a more reliable and durable repair, it’s recommended to use products specifically designed for tonneau covers or seek professional assistance.

Are there any specific tonneau cover repair kits available in the market?

Yes, there are several tonneau cover repair kits available in the market. These kits typically include patching material, adhesive, and instructions for repairing small to medium-sized holes. It’s important to choose a kit that matches the type of tonneau cover you have, such as vinyl or fabric, for the best results. You can find these repair kits at automotive supply stores or online retailers.

Can I repair a hole in my tonneau cover without removing it from my truck?

It’s possible to repair a hole in your tonneau cover without removing it from your truck, depending on the location and size of the damage. If the hole is small and accessible, you can carefully clean and patch the area without removing the cover. However, for larger or hard-to-reach holes, it may be necessary to remove the cover to ensure a proper repair.

Will repairing a hole in my tonneau cover affect its waterproofing capabilities?

Repairing a hole in your tonneau cover should not significantly affect its waterproofing capabilities if done correctly. However, it’s important to use the appropriate repair materials and techniques to ensure a proper seal. If the hole is larger or if multiple repairs have been done, there is a possibility that the waterproofing may be compromised. In such cases, it’s recommended to replace the tonneau cover if maintaining waterproofing is a priority.

Is it worth repairing a hole in my tonneau cover, or should I replace it?

The decision to repair or replace your tonneau cover depends on the extent of the damage, the cost of repair materials, and your personal preferences. If the hole is small and the rest of the cover is in good condition, repairing it can be a cost-effective solution. However, if the cover is old, worn, or has multiple areas of damage, it may be more practical to replace it altogether for long-term satisfaction and durability.

Can I prevent holes from forming in my tonneau cover?

While it may be challenging to prevent holes from forming in a tonneau cover entirely, there are steps you can take to minimize the risk. Avoid placing sharp or heavy objects directly on the cover, as they can cause tears or punctures. Regularly inspect your tonneau cover for any signs of wear or damage, and address them promptly. Additionally, consider investing in a cover made from durable materials and follow the manufacturer’s care instructions to maintain its integrity.