Do you own a Ford vehicle with a running board that’s seen better days? Perhaps it’s not retracting properly or making strange sounds when in use. Don’t worry, you’re not alone! Many Ford owners have experienced issues with their running board motors, but luckily, the solution is often simpler than you might think. In this step-by-step guide, we’ll take you through the process of repairing the motor on a Ford running board, empowering you to tackle this common problem head-on.

Just think of it as giving your beloved Ford a tune-up, ensuring it operates smoothly and flawlessly once again. So, let’s dive in and get your running board back in tip-top shape!

Table of Contents

- 1 Introduction

- 2 Tools and Materials Needed

- 3 Step 1: Safety First

- 4 Step 2: Removing the Running Board

- 5 Step 3: Accessing the Motor

- 6 Step 4: Inspecting the Motor

- 7 Step 5: Repairing or Replacing the Motor

- 8 Step 6: Reinstalling the Running Board

- 9 Step 7: Testing and Troubleshooting

- 10 Conclusion

- 11 Final Thoughts

- 12 FAQs

Introduction

Have you noticed that the motor on your Ford running board is not working properly? Don’t worry, you’re not alone. Many Ford owners have faced this issue at some point. The good news is that repairing the motor on a Ford running board is a relatively simple process that you can do yourself with just a few basic tools.

In this blog post, we will walk you through the step-by-step process of repairing the motor on a Ford running board, so you can get your vehicle back in top shape in no time. So, let’s dive in and get started!

Briefly explain the purpose of the running board motor and why it may need repair

running board motor, repair

Tools and Materials Needed

If you find that the motor on your Ford running board is in need of repair, fear not! With the right tools and materials, you can tackle this project on your own. First and foremost, you’ll need a set of basic hand tools such as a wrench and a screwdriver. Additionally, having a multimeter on hand will be helpful for testing electrical connections.

When it comes to the materials you’ll need, it’s a good idea to have replacement parts ready, such as a new motor and any necessary wiring. It’s also a good idea to have some electrical tape and zip ties on hand for securing connections. With these tools and materials at the ready, you’ll be well-equipped to take on the task of repairing the motor on your Ford running board.

Provide a comprehensive list of tools and materials necessary for the repair

When it comes to repairing something, having the right tools and materials is essential. Whether you’re fixing a leaky faucet or repairing a broken chair, having the right equipment can make all the difference. Here is a comprehensive list of tools and materials that you may need for your repair project.

First, you’ll need a basic toolkit, which should include a set of screwdrivers (both flathead and Phillips), a wrench set, pliers, and a hammer. Additionally, depending on the specific repair, you may need other tools such as a pipe wrench, wire cutters, or a utility knife. In terms of materials, you’ll likely need some screws and nails, as well as a variety of adhesives such as glue or epoxy.

You may also need some sandpaper or a file to smooth down rough edges. Lastly, don’t forget safety equipment such as goggles and gloves to protect yourself during the repair process. By having all of these tools and materials on hand, you’ll be well-prepared to tackle any repair project that comes your way.

Step 1: Safety First

If you’ve been experiencing issues with the motor on your Ford running board, it’s essential to prioritize your safety before attempting any repairs. One of the first steps to take is to make sure the vehicle is turned off and the engine is completely cooled down. This will prevent any accidental movement of the running board or potential burns from hot surfaces.

Additionally, it’s important to wear protective gear such as gloves and safety glasses to minimize the risk of injury while working on the motor. Remember, taking precautions and prioritizing safety will ensure a smoother and safer repair process for your Ford running board motor.

Explain the importance of safety precautions before starting the repair

headphone repair, safety precautions, importance, protect yourself, prevent injuries, electrical shock, cut or burn, eyes, hands, ears, personal protective equipment (PPE), goggles, gloves, earplugs, step-by-step guide, damage or destroy, electrical components, avoid accidents, ensure safety, follow instructions, unplugging, power source, disassembling, parts, tools, properly, avoid mishaps, minimize risks, accidents, complete the repair successfully, enjoy your headphones again

Mention specific safety measures to take, such as wearing gloves and disconnecting the battery

When it comes to working on your car, it’s important to prioritize safety first. Taking precautions can help prevent accidents and protect yourself from harm. One of the first safety measures to take is wearing gloves.

Gloves provide a barrier between your hands and any potential hazards, such as sharp objects or harmful chemicals. Additionally, it’s essential to disconnect the battery before starting any work. This will help prevent electrical accidents and ensure your safety while working on the car.

By prioritizing safety and taking these measures, you can have peace of mind knowing that you’re taking the necessary steps to protect yourself and prevent any mishaps.

Step 2: Removing the Running Board

Today, we’re going to talk about step 2 in repairing the motor on a Ford running board: removing the running board itself. Now, if you’ve never done this before, don’t worry – it’s actually easier than it sounds. So, grab your tools and let’s get started.

First, you’ll need to locate the mounting bolts that secure the running board to the chassis of your Ford vehicle. These bolts are usually located underneath the board itself, so you’ll need to get down on your hands and knees to find them. Once you’ve located the bolts, use a socket wrench or a ratchet to loosen and remove them.

It’s important to note that there may be different sizes of bolts, so make sure you have the right socket or wrench for the job. Once you’ve removed all the mounting bolts, the running board should be free to come off. However, some running boards may have additional fasteners or clips holding them in place.

So, take a moment to inspect the running board and see if there are any additional attachments that need to be removed. If so, use the appropriate tools to remove them before attempting to remove the running board completely. Now, it’s time to actually remove the running board.

This can be a bit tricky, as the board may be heavy and unwieldy. It’s a good idea to have a friend or family member help you with this step to ensure that you don’t accidentally drop or damage the running board. Carefully lift the running board up and away from the vehicle, making sure to support it with your hands or shoulders to prevent it from falling.

Congratulations! You’ve successfully removed the running board from your Ford vehicle. Now, you can move on to the next step in repairing the motor. Remember to take your time and be cautious throughout the process to avoid any accidents or injuries.

Provide detailed instructions on how to remove the running board from the vehicle

To remove the running board from your vehicle, follow these detailed instructions. First, locate the mounting brackets that secure the running board to the vehicle’s frame. These brackets are typically located underneath the board and may be held in place by bolts or screws.

Use a wrench or socket set to loosen and remove these fasteners. Once the mounting brackets are detached, carefully slide the running board away from the vehicle’s body. It may be helpful to have another person assist you in holding the board steady while you remove it.

Be cautious of any electrical connections or wiring that may be attached to the running board. Disconnect these connections before fully removing the board. If the running board is attached to the vehicle using adhesive or tape, use a heat gun or hairdryer to warm the adhesive.

This will make it easier to peel the board away from the vehicle’s body. Take care not to damage the vehicle’s paint or finish in the process. Once the running board is completely detached, clean the mounting area on the vehicle’s body using a mild detergent or automotive cleaner.

This will ensure a clean surface for installing a new running board, if desired. Removing a running board from your vehicle may seem daunting at first, but by following these step-by-step instructions, you can safely remove it without causing damage to your vehicle. Remember to take your time and be cautious throughout the process.

Ford running boards, removing running board, Ford model

Step 3: Accessing the Motor

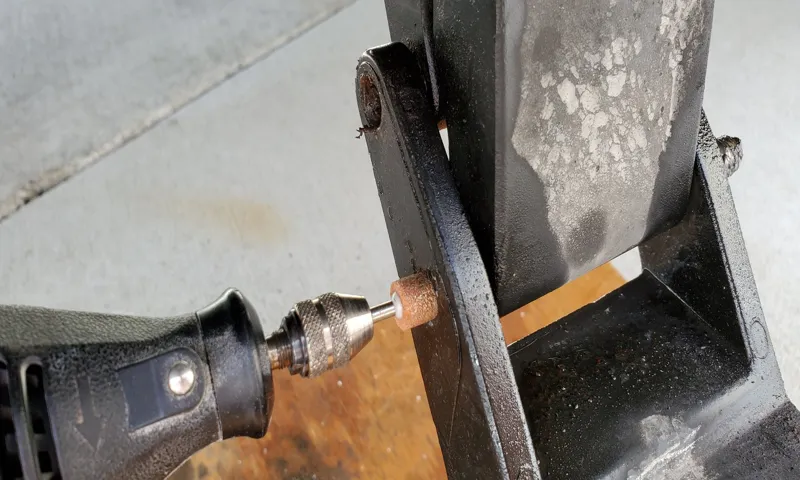

Now that we have removed the running board from the Ford truck, it’s time to access the motor. Before we begin, make sure you have all the necessary tools handy – a socket wrench, a screwdriver, and a trim removal tool. Start by locating the motor housing, which is usually located underneath the running board itself.

It might be covered by a plastic panel, so you’ll need to remove that first. Use the trim removal tool to gently pry off the panel, being careful not to damage it. Once the panel is off, you should see the motor housing.

It’s typically secured with a number of screws or bolts, so grab your socket wrench and remove them. Be sure to keep track of where each screw or bolt goes, as they may be different lengths. Once all the screws or bolts are removed, carefully lift off the motor housing.

Inside, you’ll find the motor itself, as well as any wiring or connections. Take a moment to inspect the motor for any signs of damage or wear. If everything looks good, you can proceed with the repairs or replacements as needed.

If there are any electrical connections, be sure to disconnect them before working on the motor. Remember to always refer to the vehicle’s manual or seek professional assistance if you’re not confident in your abilities. With the motor accessed, you’re one step closer to getting your Ford running board working like new again.

Explain how to locate and access the motor within the running board

To access the motor within the running board, follow these steps: First, locate the access panel on the bottom of the running board. This panel is usually secured with several screws or clips. Once located, use a screwdriver or a suitable tool to remove the screws or release the clips and remove the access panel.

Behind the access panel, you will find the motor enclosure. This enclosure houses the motor that powers the running board. Open the motor enclosure by removing any screws or clips that secure it.

Be careful while removing the enclosure as the motor might be connected to some wires. After removing the motor enclosure, you will have direct access to the motor. Look for any visible signs of damage or wear on the motor.

Check for loose connections or any debris that may be blocking the motor. If necessary, remove any debris using a soft brush or a vacuum cleaner. To disconnect the motor from the running board, locate the electrical connections.

These connections may be covered with a protective rubber or plastic cover. Carefully remove the cover and disconnect the electrical connections. Take note of the connections to ensure proper reassembly later.

Once the motor is disconnected, you can remove it from the running board. Depending on the design of the running board, the motor may be attached with screws, bolts, or clips. Use the appropriate tools to remove these fasteners and detach the motor from the running board.

Discuss any specific challenges or difficulties that may arise in this step

In step 3 of the process, accessing the motor can bring about its own set of challenges and difficulties. One of the main challenges that may arise is the physical access to the motor itself. Depending on the design and location of the motor, it may be tucked away in a hard-to-reach area, making it difficult to get to.

This can result in the need for specialized tools or techniques to gain access. Additionally, the motor may be located in a cramped or tight space, further complicating the process and potentially requiring the removal of other components or parts to create enough space for access. Another challenge that may arise is the complexity of the motor’s internal components.

Motors can be intricate and delicate machines, with multiple moving parts and electrical connections. Disassembling or accessing the motor without proper knowledge or understanding of its components can lead to damage or improper reassembly, which can result in further complications down the line. In addition, safety considerations should also be taken into account during this step.

Working with motors often involves working with electricity, which can be hazardous if proper precautions are not taken. It is important to ensure that the power source to the motor is disconnected or turned off before attempting any work on it. Following safety procedures and using personal protective equipment, such as gloves or safety glasses, can help minimize the risks associated with working with motors.

Overall, accessing the motor in step 3 of the process can present challenges related to physical access, the complexity of the motor’s components, and safety considerations. However, with the right tools, knowledge, and precautions, these challenges can be overcome, allowing for the successful completion of the task at hand.

Step 4: Inspecting the Motor

Now that we have removed the motor from the Ford running board, it’s time to inspect it to see what might be causing the issue. Start by visually examining the motor for any signs of damage or wear. Look for any loose or corroded wires, as they can lead to malfunctioning.

Check the connectors and terminals to ensure they are clean and secure. If you notice any frayed wires or broken components, they will need to be replaced. Additionally, use a multimeter to test the motor’s resistance and continuity.

This will help you determine if there are any electrical issues that need to be addressed. By thoroughly inspecting the motor, you will be able to identify any problems and find the most effective solution to repair it.

Explain how to visually inspect the motor for any visible damage or issues

motor inspection, visible damage, issues, visually inspect, checking for damage, signs of wear and tear, physical examination, motor components, abnormal sounds, abnormal vibrations, overheating, burnt marks, loose connections, worn-out parts, cracked casings, fluid leaks, inspect motor thoroughly, personal safety. In order to ensure the proper functioning of a motor and prevent any further damage, it is crucial to visually inspect it for any visible damage or issues. This step is essential in identifying potential problems before they become major concerns.

To inspect the motor, start by conducting a physical examination of its components. Check for any signs of wear and tear, such as frayed wires or loose connections. Pay attention to any abnormal sounds or vibrations, as they could indicate underlying issues.

Additionally, look for signs of overheating, such as burnt marks or discoloration. These could be indicators of electrical or mechanical problems. It is also important to inspect the motor casing for any cracks or damage, as this can affect the motor’s performance.

Finally, check for any fluid leaks, as this could be a sign of a faulty seal or gasket. By thoroughly inspecting the motor, you can identify any potential issues and take the necessary steps to address them, ensuring the motor’s longevity and your personal safety.

Suggest any additional tests or diagnostic tools that may be helpful in identifying the problem

One additional test that may be helpful in identifying the problem with the motor is a voltage test. This test involves using a multimeter to measure the voltage at different points in the motor’s electrical circuit. By checking the voltage at various points, such as at the power source, the motor terminals, and any control devices or switches, you can identify any abnormalities or fluctuations in voltage that could be impacting the motor’s performance.

This can help determine if the issue is related to a power supply problem or an issue with the motor itself. Additionally, a current test can also be conducted to measure the flow of electrical current through the motor. This can provide insight into whether the motor is drawing too much or too little current, indicating a potential problem with the motor’s internal components.

By utilizing these additional diagnostic tools, you can gain a more comprehensive understanding of the motor’s condition and better pinpoint the cause of any performance issues.

Step 5: Repairing or Replacing the Motor

Once you’ve identified the problem with the motor on your Ford running board, it’s time to get it repaired or replaced. Repairing the motor might be the more cost-effective option, but it depends on the extent of the damage. If the motor is just jammed or making strange noises, you may be able to take it apart and fix it yourself.

However, if the motor is completely burnt out or has other major issues, it might be better to replace it altogether. This will require purchasing a new motor and installing it yourself or taking it to a professional mechanic. Make sure to consult the owner’s manual for your Ford running board for specific instructions on how to repair or replace the motor.

With a bit of patience and some basic mechanical skills, you can have your running board motor up and running smoothly again in no time.

Offer step-by-step instructions on how to repair the motor, if possible

If you’re having trouble with your motor and need to fix it, don’t worry! I’m here to guide you through the process step by step. The first thing you’ll need to do is identify whether the motor can be repaired or if it needs to be replaced altogether. A motor can stop working for a variety of reasons, such as worn-out components or electrical issues.

Once you’ve determined the root cause of the problem, you can proceed with the appropriate solution. If the motor can be repaired, you’ll need to gather the necessary tools and equipment. This may include screwdrivers, pliers, and replacement parts if needed.

The next step is to carefully disassemble the motor, taking note of the order and position of each component. Inspect each part for any signs of damage or wear and tear. If you come across a faulty component, it can usually be replaced with a new one.

However, if the damage is extensive or the motor is too old, it may be more practical to replace the entire motor instead. Remember to follow the manufacturer’s instructions for disassembly and reassembly, as each motor may have specific requirements. Once you’ve repaired or replaced the motor, test it out to ensure it’s working properly.

By following these steps, you’ll be well on your way to getting your motor back up and running smoothly again!

If the motor cannot be repaired, provide instructions on how to replace it

replace motor, instructions, cannot be repaired So, you’ve tried everything you can to repair your motor, but unfortunately, it just isn’t salvageable. Don’t worry, because replacing the motor is a relatively simple process that you can do yourself with just a few tools and a little know-how. First, you’ll need to make sure you have the right replacement motor for your needs.

Check the specifications of your original motor and find one that matches in terms of horsepower, voltage, RPM, and any other important factors. You don’t want to end up with a motor that is too weak or too powerful for your needs. Once you have the new motor, you’ll need to disconnect the power supply to the old motor.

This is crucial for safety reasons – you don’t want any accidents while you’re working on the replacement. Make sure to turn off the power and unplug any cords before starting. Next, you’ll need to remove the old motor from its housing.

Depending on the design of your particular motor, this may involve unscrewing bolts, disconnecting wires, or removing brackets. Take care to keep track of any screws or small parts that you remove so that you can easily reassemble everything later. With the old motor out of the way, you can now install the new motor.

Place it into the housing and secure it in place using the appropriate screws or brackets. Make sure it is positioned correctly and aligned properly with any shafts that it needs to connect to. Finally, reconnect any wires that were disconnected during the removal process.

Double-check that everything is connected securely and that there are no loose wires that could cause problems later on. Once you are confident that everything is in place, you can turn the power back on and test the new motor. By following these step-by-step instructions, you should be able to easily replace a motor that cannot be repaired.

Step 6: Reinstalling the Running Board

Now that the motor on your Ford running board has been repaired, it’s time to reinstall it. This is a relatively simple process, but it’s important to follow the steps correctly to ensure everything is properly aligned. First, locate the mounting brackets on the underside of your vehicle.

These brackets should be in the same position they were in before you removed the running board. If they are not, adjust them accordingly. Next, slide the running board onto the mounting brackets.

You may need to elevate the board slightly to align it with the brackets. Once the board is in position, secure it in place by tightening the bolts or screws that hold it to the brackets. Finally, test the running board to ensure it is functioning properly.

Activate the motor and watch as the board extends and retracts. If everything is working as it should, you’re all set! By following these steps, you can successfully reinstall the running board on your Ford vehicle after repairing the motor. Now you can enjoy the convenience and functionality of your running board once again.

Provide detailed instructions on how to reattach the running board to the vehicle

One of the final steps in reinstalling a running board on your vehicle is to actually attach it back onto your vehicle. This step may seem daunting, but with the right instructions, it can be a relatively straightforward process. Start by ensuring that the running board is in the correct position and align it with the brackets or mounting points on your vehicle.

Once aligned, carefully lift or slide the running board onto the brackets or mounting points. Depending on the type of running board, you may need to use screws, bolts, or other fasteners to secure it in place. Make sure to tighten the fasteners securely, ensuring that the running board is stable and won’t wobble.

Double-check that the running board is properly aligned and level with the vehicle before moving on to the next step. If needed, make any necessary adjustments to ensure a perfect fit. Take your time and be patient during this step as it’s important to get it right for both aesthetics and functionality.

Ford running board installation precautions When reinstalling the running board on your Ford model, there are a few specific steps and precautions to keep in mind. Firstly, make sure to clean the mounting area thoroughly to ensure a secure and long-lasting installation. Remove any dirt, debris, or old adhesive using a mild detergent and a soft brush.

Secondly, check the condition of the running board and its mounting hardware. Inspect for any signs of damage, such as cracks or rust, and replace any worn-out or faulty components. Additionally, apply a corrosion-resistant coating to the mounting area to protect against future damage.

Finally, when attaching the running board back onto the Ford, tighten the mounting bolts to the manufacturer’s specifications. This will ensure a tight fit and prevent any potential loosening or rattling over time. Following these precautions will help guarantee a successful and durable running board installation on your Ford vehicle.

Step 7: Testing and Troubleshooting

So, you’ve taken on the task of repairing the motor on your Ford running board. Now it’s time to put your skills to the test and see if you’ve successfully fixed the issue. The first step in testing the motor is to make sure that it is receiving power.

To do this, you will need a multimeter. Simply set the multimeter to the voltage setting and place the probes on the positive and negative terminals of the motor. If you get a reading close to the rated voltage of the motor, then you can be confident that it is receiving power.

If not, you may need to check the electrical connections or the fuse for any potential issues. Once you’ve determined that the motor is receiving power, the next step is to test the motor itself. To do this, you will need to disconnect the motor from any mechanical components and apply power directly to it.

You can do this by temporarily connecting it to a power source, such as a car battery. Be sure to use caution when doing this, as you will be working with live electrical components. If the motor does not start running when power is applied, it is likely that there is an issue with the motor itself.

In this case, you may need to consider replacing the motor or further troubleshooting to identify the specific issue. However, if the motor does start running smoothly, then congratulations! You have successfully repaired the motor on your Ford running board. Remember, troubleshooting and testing can sometimes be a process of trial and error.

Don’t be discouraged if things don’t go smoothly right away. Take your time, follow the steps carefully, and don’t hesitate to seek out professional help if needed. By staying patient and persistent, you will be able to successfully repair the motor on your Ford running board and get it back in working order.

Explain how to test the repaired or replaced motor to ensure it is functioning properly

testing the repaired or replaced motor, ensure it is functioning properly, troubleshooting, step-by-step guide, functioning optimally, electrical usage, power load, check for abnormal sounds, overheating, overheating issues, inspect the motor, physical damage, loose connections, misalignment, damaged or worn-out components, power supply, electrical continuity, voltage, amperage, insulation resistance, motor rotation, functionality, motor performance, load testing, reassemble, final inspection After repairing or replacing a motor, it is essential to test it thoroughly to ensure it is functioning properly. This step is crucial to ensure that the motor is functioning optimally and can handle its electrical usage. To begin the testing process, you should first check for any abnormal sounds or signs of overheating.

These can be indications of underlying issues that may need to be addressed. Once you have inspected the motor for physical damage, loose connections, misalignment, or any other issues, you can proceed with the testing. To test the motor’s functionality, you need to verify its performance under load.

Load testing involves subjecting the motor to a power load to see if it can handle the expected workload. You can do this by connecting the motor to a power supply and measuring the electrical continuity, voltage, and amperage. This will help you determine if the motor’s electrical system is functioning correctly.

In addition to electrical testing, you should also check the motor’s insulation resistance. Insulation resistance testing measures the effectiveness of the motor’s insulation against electrical leakage. This is important to ensure the motor’s safety and prevent any potential electrical hazards.

A high insulation resistance reading indicates that the motor’s insulation is in good condition. Once you have completed the electrical testing, you can test the motor’s rotation. Ensure that the motor rotates smoothly and in the correct direction.

Any issues with motor rotation can indicate problems with its internal components or wiring. Finally, after testing the motor, you can reassemble it and conduct a final inspection. This inspection should include checking for any loose connections, listening for abnormal sounds, and ensuring that the motor operates smoothly and without overheating.

Offer troubleshooting tips for common issues that may arise after the repair

After completing a repair, it is important to thoroughly test the device to ensure that all issues have been resolved. However, there may be instances where new problems arise or the original issue persists. In such cases, troubleshooting techniques can come in handy.

One common issue that may occur is a faulty connection. This can be resolved by checking all cables and connectors to ensure they are properly connected. Additionally, software issues may arise after a repair.

To troubleshoot software problems, it is recommended to perform a system reset or reinstall the necessary software. Another common issue is a hardware malfunction. In this case, it is advisable to check all components to identify any damaged or faulty parts.

By following these troubleshooting tips, you can overcome common issues that may arise post-repair and ensure that the device is fully functional.

Conclusion

In conclusion, repairing the motor on a Ford running board is like giving a boost of life to your vehicle’s fancy footwork. Just like a salsa dancer with a limp, a malfunctioning running board motor can really put a damper on the overall performance and style of your beloved Ford. But fear not, intrepid DIY-ers! With a little patience, a touch of ingenuity, and a dash of mechanical finesse, you can restore your running board motor to its former glory.

Now, repairing a motor may seem like a daunting task, but remember, even the most intricate machines are just a series of smaller, interconnected parts. Think of it like a complex puzzle, where each piece plays a crucial role in the grand design. First and foremost, arm yourself with the necessary tools: a socket wrench, wire stripper, soldering iron, and a healthy dose of determination are all must-haves for the job.

Once you’ve gathered your tools, it’s time to dive right into the nitty-gritty of the motor. Start by removing the motor cover, being careful not to lose any screws or springs along the way (because let’s face it, a lost screw can really make you feel like you’re losing your marbles!). Take a good look inside to assess the damage – is there a wire loose or a connection severed? If so, grab your soldering iron and work your magic to re-establish the electrical flow, as if you’re conducting a symphony of currents.

Sometimes, the issue might not be as straightforward as a loose wire. In these cases, channel your inner detective and follow the clues. Is there a strange noise emanating from the motor? Perhaps a suspicious smell that tickles your olfactory senses? Don your metaphorical deerstalker hat and investigate – it could be a worn-out gear or a faulty bearing that’s causing the ruckus.

Replace these troubled components, and your running board motor will be back to humming along smoothly. And finally, remember, repairing a motor is not a task to be taken lightly. It requires patience, attention to detail, and a willingness to get your hands dirty.

You might encounter setbacks along the way, but don’t let that discourage you. Success lies in persistence and the belief that you are capable of anything you set your mind to – just like your Ford running board, which can once again conquer any obstacle with its renewed motor. So, my friends, get ready to unleash your inner mechanic and wave goodbye to that malfunctioning running board motor.

Recap the main steps and emphasize the importance of proper motor repair

motor repair, testing and troubleshooting, proper motor repair When it comes to motor repair, testing and troubleshooting play a crucial role in ensuring that the motor is functioning properly. Step 7 of the motor repair process involves thorough testing and troubleshooting to identify any issues or malfunctions. This step is of utmost importance as it allows technicians to determine the root cause of the problem and make the necessary repairs.

Testing involves running the motor and monitoring its performance, checking for any abnormal sounds or vibrations, and measuring parameters such as voltage, current, and temperature. Troubleshooting, on the other hand, involves systematically identifying and resolving issues that may be affecting the motor’s performance. This can include checking electrical connections, inspecting components for damage, and analyzing data from diagnostic tools.

Proper testing and troubleshooting ensure that the motor is repaired correctly and prevents any further damage or breakdowns. It is essential for ensuring the motor’s reliability, efficiency, and longevity.

Encourage the reader to seek professional help if they are not comfortable with the repair process

In the final step of repairing your electronic device, it’s time to put it to the test. This step is crucial in ensuring that the repairs were successful and that the device is functioning properly. However, if you are not comfortable with the testing and troubleshooting process, it’s important to seek professional help.

Testing and troubleshooting electronic devices can be complex and sensitive, requiring knowledge and expertise. It’s better to be safe than sorry when it comes to your valuable devices. Professional technicians have the experience and tools necessary to accurately assess the functionality of the device and address any issues that may arise.

So, if you’re unsure about how to properly test and troubleshoot your repaired device, don’t hesitate to reach out to a professional. They can ensure that everything is in working order and give you peace of mind knowing that your device is in good hands. Remember, it’s always better to be safe than sorry.

Final Thoughts

If you find yourself needing to repair the motor on a Ford running board, don’t fret! Though it may seem like a daunting task, with a bit of patience and some basic tools, you can get your running board functioning like new again. The first step is to identify the issue. Is the motor not working at all, or is it making strange noises? Once you know what the problem is, you can proceed with the necessary repairs.

In some cases, the motor may just need to be cleaned and lubricated. Other times, you may need to replace the motor altogether. Make sure to consult your vehicle’s manual for specific instructions on how to remove and install a new motor.

With the right tools and some determination, you can have your Ford running board back in working order in no time. So don’t hesitate to tackle this repair yourself, and save some money while you’re at it!

Provide any additional tips or advice for maintaining the running board motor in the future

Final Thoughts To ensure the longevity and optimal performance of your running board motor, it is important to maintain it regularly. One key tip is to inspect the motor and its components regularly for any signs of damage or wear. This includes checking the wiring, connections, and brushes for any wear or corrosion.

If any issues are detected, it is important to address them promptly to prevent further damage. Additionally, keep the motor clean and free from dust and debris, as this can cause overheating and decrease performance. Regularly lubricate the motor and its moving parts to reduce friction and ensure smooth operation.

Lastly, be mindful of any potential water damage, especially if the motor is exposed to the elements. By following these simple tips, you can prolong the lifespan of your running board motor and enjoy its benefits for years to come.

As we conclude this blog series on our favorite repair stories, we hope you have enjoyed reading about some of the incredible feats of ingenuity and resourcefulness that people have accomplished. These stories remind us that with a little creativity and determination, we can fix just about anything. From the musician who repaired their broken piano key with a paperclip to the grandmother who fixed a leaky faucet with a hairpin, these tales of DIY success inspire us to take matters into our own hands and find solutions to our everyday problems.

But now, we want to hear from you! Do you have a repair story of your own? Whether it’s a small fix or a major renovation, we want to hear about the challenges you faced and the creative solutions you came up with. Share your experiences in the comments below and let’s celebrate the power of repair together! Don’t be shy – your story might just inspire someone else to tackle their own repairs. So go ahead, share your wisdom and join the conversation!

FAQs

How to repair a motor on a Ford running board?

To repair the motor on a Ford running board, you will need to first remove the old motor by disconnecting the wiring harness and removing any mounting screws. Then, install the new motor by aligning it with the mounting holes and securing it with the screws. Finally, reconnect the wiring harness and test the motor to ensure it is functioning properly.

What are the common signs of a faulty running board motor on a Ford?

Some common signs of a faulty running board motor on a Ford include the running board not retracting or extending properly, loud grinding or clicking noises coming from the motor, or the motor not responding at all. If you notice any of these issues, it is likely that your motor needs to be repaired or replaced.

Can I repair a Ford running board motor myself or should I take it to a professional?

The repair of a Ford running board motor can be done by yourself if you have some experience with automotive repairs. However, if you are unsure or uncomfortable working with electrical systems, it is recommended to take it to a professional mechanic who specializes in these types of repairs.

Where can I purchase a replacement motor for a Ford running board?

Replacement motors for Ford running boards can be purchased from various online retailers, such as auto parts stores or Ford dealership websites. It is important to ensure that you are purchasing the correct motor for your specific Ford model and year.

How much does it typically cost to repair a motor on a Ford running board?

The cost of repairing a motor on a Ford running board can vary depending on the extent of the damage and the labor rates in your area. On average, the cost can range from $200 to $500, which includes the price of the replacement motor and the labor required for the repair.

How long does it take to repair a motor on a Ford running board?

The time required to repair a motor on a Ford running board can depend on various factors, such as the level of expertise of the person performing the repair and the accessibility of the motor. On average, it can take anywhere from 1 to 3 hours to complete the repair.

Are there any preventive measures to avoid motor damage on a Ford running board?

To prevent motor damage on a Ford running board, it is important to regularly inspect and clean the running board components. This can help to remove any debris or obstructions that can cause stress on the motor. Additionally, avoid excessive use of the running board and be gentle when retracting or extending it to minimize wear and tear on the motor.