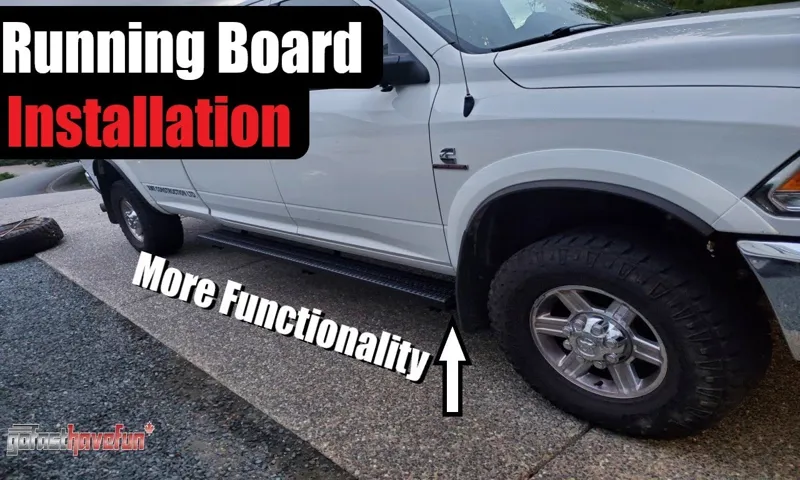

Are you looking to remove the running boards on your Dodge Ram 3500 but don’t know where to start? Well, you’ve come to the right place! Removing the running boards on a truck can be a bit of a tricky task, but with the right tools and a little bit of patience, you can have them off in no time. Running boards are a popular addition to trucks like the Dodge Ram 3500, as they provide a convenient step for accessing the cabin or the truck bed. However, there may come a time when you want to remove them for various reasons.

Whether you’re looking to replace them with new ones, switch to a different style, or simply want to give your truck a sleeker look, removing the running boards is a relatively straightforward process. Before you get started, it’s essential to make sure you have all the necessary tools on hand. You’ll typically need a socket set, a wrench, a pry bar, and possibly a rubber mallet.

Additionally, having a set of gloves and safety glasses is always a good idea to protect yourself during the removal process. Now, let’s jump right into it! The first step is to locate the mounting brackets that attach the running boards to the truck’s frame. These brackets are usually secured with bolts or screws, so you’ll need to use your socket set or wrench to remove them.

Start by loosening the bolts or screws, but don’t remove them fully just yet. Once the brackets are loose, you can then slide the running board forward or backward to disengage it from the brackets. This might require a bit of force, so don’t be afraid to give it a firm tug if needed.

If the running board is stubborn and doesn’t budge easily, you can use a pry bar or a rubber mallet to gently nudge it loose. After the running board has been disengaged from the brackets, you can finally remove the bolts or screws fully and detach the brackets from the truck’s frame. Be sure to keep track of all the hardware as you’ll need it if you decide to reinstall the running boards later on.

With the brackets and hardware removed, you’ll now have a sleeker-looking Dodge Ram 3500 ready for whatever adventure lies ahead. Whether you plan to replace the running boards or leave them off entirely, this simple removal process allows you to customize your truck to your liking. Remember, it’s always a good idea to consult your truck’s owner’s manual for specific instructions or reach out to a professional if you’re unsure about any step of the process.

Table of Contents

Introduction

Are you looking to remove the stock running board from your Dodge Ram 3500? Well, you’ve come to the right place! Taking off the running board may seem like a daunting task, but with the right tools and a little bit of know-how, you can have it off in no time. First, gather the necessary tools such as a socket wrench, a pry bar, and a rubber mallet. Next, locate the bolts that are holding the running board in place.

These bolts are usually located underneath the truck, towards the front and back of the board. Use the socket wrench to loosen and remove the bolts, taking care not to strip them in the process. Once all of the bolts have been removed, you can use the pry bar and rubber mallet to gently pry the running board away from the vehicle.

Be sure to take your time and work slowly to avoid damaging the truck or injuring yourself. And just like that, you’ve successfully removed the stock running board from your Dodge Ram 3500!

What is a Running Board?

running board, running boards

Why Remove the Running Board?

running board, remove, benefits Introduction: Are you considering removing the running board from your vehicle? Well, you’re not alone! Many car owners are opting to take off this accessory for various reasons. In this article, we’ll explore the reasons why removing the running board can be beneficial and why it might be worth considering. Whether you’re looking to improve the aesthetics of your vehicle or enhance its functionality, read on to discover the advantages of removing the running board.

Tools and Materials

If you’re wondering how to take the stock running board off your Dodge Ram 3500, don’t worry, it’s actually a pretty straightforward process. To do this, you’ll need a few basic tools and materials. First and foremost, you’ll need a socket wrench with the appropriate size socket to fit the bolts on the running board.

You’ll also need a pry bar or a flathead screwdriver to help loosen any stubborn bolts or clips. Depending on the specific model of your truck, you may also need a torque wrench to loosen or tighten certain bolts. Additionally, it’s always a good idea to have some penetrating oil on hand to help loosen corroded or rusted bolts.

Lastly, don’t forget to have a safe and sturdy place to stand while you’re working, such as a step ladder or a pair of sawhorses. With these tools and materials at your disposal, you’ll be able to remove the stock running board from your Dodge Ram 3500 in no time.

Tools

“Tools and Materials” When it comes to DIY projects, having the right tools and materials can make all the difference. After all, you wouldn’t want to start a project only to realize halfway through that you don’t have the necessary tools to get the job done. That’s why it’s important to have a well-stocked toolbox and to know which materials are needed for each project.

One essential tool that should be in every DIYer’s toolbox is a good set of screwdrivers. From assembling furniture to fixing a loose doorknob, screwdrivers are a must-have. It’s also a good idea to have a variety of sizes and types, as different screws require different screwdrivers.

Another tool that is indispensable for DIY projects is a drill. Whether you need to hang a picture or build a bookshelf, a drill will make the job much easier. Look for a drill that is cordless and has multiple speed settings, as this will give you more versatility.

Having a good set of pliers is also a must. Pliers are great for gripping onto things, cutting wires, or even bending metal. They come in various shapes and sizes, so choose the ones that best fit your needs.

When it comes to materials, it’s always a good idea to have a stock of nails, screws, and bolts in different sizes. You never know when you’ll need them, and it’s better to be prepared. If you’re working with wood, having a selection of sandpaper is essential.

This will allow you to smooth out any rough edges or imperfections before applying paint or varnish. And of course, no DIY project would be complete without the proper safety gear. Always wear safety goggles when using power tools, and consider wearing gloves when handling sharp objects or working with chemicals.

Materials

tools and materials, DIY projects, woodworking, home improvement, crafting, construction projects, hand tools, power tools, measuring tools, safety equipment, materials such as wood, metal, plastic, screws, nails, adhesives, paint, brushes, and varnish. When it comes to DIY projects, having the right tools and materials can make all the difference. Whether you’re a woodworking enthusiast, a home improvement guru, or just enjoy crafting, it’s important to have a well-stocked toolbox.

Hand tools are a great place to start, with essentials like hammers, screwdrivers, and wrenches. Power tools can also be a big help, with options like drills, saws, and sanders to make your projects go faster and smoother. Measuring tools, like tape measures and levels, are crucial for ensuring accuracy and precision.

And let’s not forget about safety equipment, such as goggles, gloves, and masks, to protect yourself while working with these tools. Of course, tools are only part of the equation. Having the right materials is also essential for any project.

Depending on your needs, you may be working with wood, metal, plastic, or a combination of materials. Make sure you have the appropriate screws, nails, and adhesives to join these materials together. If you’re looking to add some color or finish to your project, paint, brushes, and varnish are must-haves.

And don’t forget about the little things, like sandpaper, tape, and clamps, that can make a big difference in the quality of your work. When it comes to tools and materials, it’s important to invest in quality products that will stand the test of time. While you may be tempted to opt for cheaper options, spending a little extra upfront can save you time and frustration in the long run.

Look for reputable brands that are known for their durability and reliability. And make sure to take proper care of your tools and materials, such as cleaning and storing them correctly, to ensure they last as long as possible. So whether you’re embarking on a construction project, tackling a woodworking masterpiece, or simply sprucing up your home with some DIY crafts, make sure you have the right tools and materials on hand.

Step-by-Step Guide

If you’re looking to remove the stock running board on your Dodge Ram 3500, you’ve come to the right place. Taking off the running board is a relatively simple process that can be done in just a few steps. First, locate the mounting brackets on the underside of the running board.

These brackets are attached to the frame of your truck and are what hold the running board in place. Once you’ve identified the brackets, you’ll need to remove the bolts that secure them to the frame. This can typically be done using a socket wrench or a pair of pliers.

Once the bolts are removed, you should be able to slide the running board off of the brackets. Make sure to support the weight of the running board as you do this to prevent it from falling and causing damage. With the running board removed, you can now clean the area and install any aftermarket modifications or accessories you desire.

Removing the stock running board can give your Dodge Ram 3500 a sleeker, more customized appearance and open up opportunities for additional upgrades.

Step 1: Prepare the Vehicle

When it comes to preparing your vehicle for a road trip, there are a few important steps to follow to ensure a smooth and safe journey. Step 1 is all about getting your vehicle ready for the road. There are a few key tasks that you should complete before hitting the pavement.

First, check your vehicle’s fluids, including oil, coolant, and brake fluid. You want to make sure that all of these levels are at their appropriate levels to prevent any potential issues while on the road. Next, check your tire pressure and tread depth.

Ensuring that your tires are properly inflated and have enough tread is crucial for maintaining traction and handling. It’s also a good idea to inspect your vehicle’s lights, including headlights, taillights, and turn signals, to make sure they are all functioning properly. Lastly, make sure you have any necessary tools and equipment in your vehicle, such as a spare tire, jack, and jumper cables, in case of any unexpected emergencies.

By taking the time to properly prepare your vehicle, you can have peace of mind knowing that you are ready for whatever the road may throw your way.

Step 2: Locate the Mounting Brackets

In this step-by-step guide, we’ll walk you through the process of locating the mounting brackets for your project. Mounting brackets are essential for securely attaching a variety of objects, such as shelves, TVs, or curtain rods, to walls or other surfaces. The first thing you’ll need to do is gather your tools and materials: a stud finder, a pencil, and a level.

Once you have your supplies ready, start by using the stud finder to locate the studs in the wall. Mark the location of the studs with a pencil. Next, determine the desired height or position for your mounting brackets.

Use a level to ensure your brackets will be straight. Now, it’s time to locate the mounting brackets. Typically, they will come with the object you are attaching, such as a shelf or a TV mount.

Check the packaging or instructions to see if the brackets are included. If they are, make sure to double-check that you have all the necessary parts. If the brackets are not included, you can purchase them separately at a hardware store.

Look for brackets that are compatible with your specific project and the weight it will need to support. Once you have your mounting brackets in hand, you’re ready to move on to the next step.

Step 3: Remove the Bolts

In the third step of removing bolts, we tackle the task head-on and give those stubborn bolts a good ‘ole twist to loosen them up. But before we dive in, it’s essential to gather all the necessary tools for the job. Grab a trusty wrench or socket wrench, and don’t forget to put on those handy work gloves to protect your hands.

Once you’re fully equipped, it’s time to get down to business. Now, let’s focus on those bolts, which are holding everything together. These little guys can be quite stubborn, rusted, or simply stuck.

But fear not! With a little bit of effort and the right technique, you can easily remove them. First, position your wrench or socket wrench firmly onto the bolt head. Apply steady pressure, turning it counterclockwise to release the bolt.

Here’s a handy pro tip: if you find that the bolt isn’t budging, you can add a little bit of penetrant, such as WD-40, to help loosen things up. Allow the penetrant to soak in for a few minutes, and then give it another go. Sometimes, a bit of extra lubrication is all it takes to conquer those tight bolts.

Remember to take it slow and apply even pressure as you work to remove each bolt. Avoid using excessive force or rushing the process, as this can lead to stripped bolt heads or even injury. Take breaks if needed, and don’t be discouraged if some bolts are more stubborn than others – perseverance is key! Once you successfully remove a bolt, set it aside in a safe place and move on to the next one.

Repeat the process until all the bolts are carefully removed. Congratulations, you’re one step closer to your goal! In conclusion, removing bolts may seem like a daunting task, but with the right tools, technique, and a little bit of patience, you’ll be able to conquer even the most stubborn bolts. Just remember to gather your tools, apply steady pressure, and take your time.

Step 4: Disconnect the Wiring (if applicable)

wireless doorbell, disconnect the wiring, wiring connection, easy method, battery-powered option, old wired doorbell, electrical junction box, electrical wires

Step 5: Remove the Running Board

In this step-by-step guide, we’ll walk you through the process of removing the running board from your vehicle. Whether you’re looking to replace the running board or just need to access the underside of your car for maintenance, removing the running board is an important task. To begin, you’ll want to gather the necessary tools for the job, including a socket wrench, a flat-head screwdriver, and a pry bar.

Once you have all your tools at hand, you can start by detaching the running board from the vehicle’s frame. This usually involves removing a series of bolts or screws that hold the running board in place. Next, you’ll need to locate the electrical connections, if applicable, and disconnect them carefully.

It’s important to take your time during this step to avoid damaging any wires or connectors. Lastly, you can use a pry bar to gently lift the running board away from the vehicle, releasing any clips or brackets that may be holding it in place. With the running board removed, you’ll have access to the area beneath your car, making repairs and maintenance tasks much easier.

Tips and Precautions

If you’re looking to take the running board off your Dodge Ram 3500, there are a few tips and precautions you should keep in mind. First, make sure you have all the necessary tools on hand before you begin. This may include a socket set, a wrench, and a pry bar.

Next, park your truck on a level surface and engage the parking brake to ensure it doesn’t roll while you’re working. It’s also a good idea to wear work gloves to protect your hands from any sharp edges or debris. When removing the running board, start by removing any screws or bolts that are holding it in place.

Carefully lift and slide the running board away from the truck, being mindful of any electrical connections that may need to be disconnected. It’s important to take your time and work slowly to avoid damaging either the running board or your truck. Once the running board is removed, inspect the area for any dirt or debris that may have accumulated.

Use a clean cloth or brush to remove any buildup before installing a new running board or leaving the area exposed. By following these tips and taking the necessary precautions, you can safely and effectively remove the running board from your Dodge Ram 3500.

Tip 1: Use Proper Safety Precautions

safety precautions, proper safety measures In any activity or situation where safety is a concern, it’s crucial to take proper safety precautions. Whether you’re working in a hazardous environment, participating in a high-risk sport, or even just doing household chores, following the necessary safety measures can make all the difference. One important tip when it comes to safety is to always wear the appropriate protective gear.

This can include helmets, gloves, goggles, and other safety equipment that is specific to the task at hand. For example, if you’re using power tools, you should always wear safety glasses to protect your eyes from flying debris. Similarly, if you’re participating in a contact sport, wearing the right protective gear can help prevent injuries.

Another crucial aspect of safety is to be aware of your surroundings and potential hazards. This means being attentive and observant, and taking the necessary steps to eliminate or minimize risks. For example, if you’re working with chemicals, it’s important to ensure adequate ventilation and to follow proper handling procedures.

Similarly, if you’re going for a hike, it’s important to familiarize yourself with the trail and to be prepared for any potential dangers. Lastly, always follow instructions and guidelines provided by experts or professionals. Whether it’s operating a machinery or participating in a new activity, make sure you know how to use it properly and are aware of all safety guidelines.

This can help prevent accidents and ensure your own safety as well as the safety of those around you. In conclusion, using proper safety precautions is essential in any activity or situation where safety is a concern. By wearing protective gear, being aware of your surroundings, and following instructions, you can significantly reduce the risk of accidents or injuries.

Remember, safety should never be taken lightly, and it’s always better to be safe than sorry.

Tip 2: Keep Track of Bolts and Hardware

Keeping track of bolts and hardware is an important aspect of any project, whether it’s building furniture or repairing a car. It’s all too easy to lose track of screws, nuts, and bolts, especially if you’re working in a cluttered space or if you have multiple projects going on at once. So, how can you make sure you don’t misplace or lose these small but crucial items? One simple solution is to use a magnetic tray or bowl to hold your bolts and hardware.

The magnet will keep them in place, preventing them from rolling off your workbench or getting lost in the debris. Plus, you can easily move the tray around as needed, ensuring that your hardware is always within reach. Another useful tip is to label and organize your bolts and hardware.

This can be done by using small plastic containers or bags with labels indicating the size or purpose of each item. By keeping them sorted and labeled, you’ll be able to quickly find the specific bolt or hardware piece you need without wasting time searching through a jumbled mess. Additionally, it’s helpful to have a designated storage system for your bolts and hardware.

Whether it’s a toolbox, drawer, or shelf, having a designated spot will help you keep everything in one place and avoid misplacing items. It’s also a good idea to periodically sort through your collection and remove any damaged or unusable items to keep your storage space organized and clutter-free. In conclusion, keeping track of bolts and hardware is essential to the success of any project.

By using a magnetic tray, labeling and organizing your items, and having a designated storage system, you’ll be able to keep everything in order and easily accessible. So, the next time you embark on a project, don’t forget to keep a close eye on those small but crucial pieces!

Tip 3: Clean and Inspect the Running Board

The running board of your vehicle is not only functional but also adds a touch of style. It’s important to keep it clean and inspect it regularly to ensure its longevity and prevent any potential issues. To clean the running board, start by removing any debris or dirt with a brush or a hose.

Use a mild detergent and water to scrub away any stains or grime. Rinse thoroughly and dry with a clean cloth. Once clean, take the time to inspect the running board for any signs of damage or wear.

Look for cracks, rust, or loose fittings. If you spot any issues, it’s important to address them promptly to prevent further damage and keep your running board in top shape. By keeping your running board clean and inspecting it regularly, you can ensure it not only looks great but also serves its purpose effectively.

Precaution: Watch Out for Sharp Edges

sharp edges, precautions, watch out, safety tips, potential dangers, injuries, cuts, abrasions, safety gear, protective equipment, awareness, caution, inspect, surfaces, sharp objects, handle safely, preventive measures, supervise children, household items, furniture, construction materials, cautious approach, safety awareness, injury prevention. Precaution: Watch Out for Sharp Edges When it comes to safety, taking precautions is essential to avoid potential dangers and injuries. One common hazard that often goes unnoticed is sharp edges.

Whether in our homes or workplaces, sharp edges can pose a significant risk of cuts and abrasions. It’s important to be aware of these hazards and take the necessary steps to ensure our safety. One of the most effective ways to prevent injuries from sharp edges is to use protective equipment, such as gloves or safety glasses, when handling objects or materials with sharp edges.

Additionally, it is crucial to inspect the surfaces of furniture or household items for any sharp objects and handle them with caution. Supervising children is another important aspect of preventing injuries from sharp edges. Children are naturally curious and may not be aware of the potential dangers around them.

By providing them with a safe environment and teaching them about the hazards of sharp edges, we can minimize the risk of accidents. In our daily lives, we come across sharp edges in various forms, be it in the form of household items or construction materials. It is important to approach these objects with a cautious mindset and ensure proper safety measures are in place.

To protect ourselves and others from injuries, it is crucial to develop a sense of safety awareness regarding sharp edges. By incorporating a cautious approach and being mindful of our surroundings, we can prevent accidents caused by sharp edges and maintain a safe environment. Remember, safety starts with us!

Conclusion

So, there you have it – how to take the stock running board off your Dodge Ram 3500. It may seem like a daunting task, but with a little bit of patience and the right tools, you’ll have those pesky running boards off in no time. Remember, this is a great opportunity to embrace your inner DIY-er and show off your handy skills to your friends.

And who knows, maybe you’ll discover a hidden talent for automotive maintenance along the way. Now that you’re armed with this knowledge, you can confidently tackle this project and leave those stock running boards in the dust. And who knows, maybe you’ll even inspire others to take on their own truck modifications.

Just remember, safety first – make sure to use protective gear and take the necessary precautions when working on your vehicle. And if all else fails, don’t be afraid to call in the professionals. So go ahead, grab your toolbox and get ready to give your Dodge Ram 3500 a new look without those stock running boards.

Happy wrenching!”

FAQs

How do I remove the running board from a Dodge Ram 3500?

To remove the running board from a Dodge Ram 3500, first locate the mounting brackets underneath the board. Use a socket wrench to remove the bolts that connect the brackets to the truck’s frame. Once the bolts are removed, carefully lift the running board off of the brackets.

Can I remove the running board myself or do I need professional help?

It is possible to remove the running board from a Dodge Ram 3500 yourself, but it may require some physical strength and the right tools. If you are not comfortable or confident in your abilities, it is recommended to seek professional help to avoid any damage or injury.

What tools do I need to remove the running board from a Dodge Ram 3500?

To remove the running board from a Dodge Ram 3500, you will need a socket wrench with the correct size socket to fit the mounting bracket bolts. It is also helpful to have a pry bar or rubber mallet to gently pry the running board away from the brackets if it is stuck.

Are there any precautions I need to take before removing the running board?

Before removing the running board from a Dodge Ram 3500, make sure to park the truck on a flat, stable surface and engage the parking brake for added safety. It is also a good idea to disconnect the truck’s battery to prevent any electrical issues.

How long does it typically take to remove a running board from a Dodge Ram 3500?

The time it takes to remove a running board from a Dodge Ram 3500 can vary depending on your experience and the condition of the board. On average, it may take anywhere from 30 minutes to an hour to complete the removal process.

Can I reuse the running board after removing it from my Dodge Ram 3500?

Yes, you can reuse the running board after removing it from your Dodge Ram 3500, if it is still in good condition. Make sure to clean the board thoroughly and inspect it for any damage or wear before reinstalling it.

What should I do if the running board is stuck or difficult to remove?

If the running board on your Dodge Ram 3500 is stuck or difficult to remove, try using a rubber mallet or pry bar to gently loosen it from the mounting brackets. Avoid using excessive force to prevent any damage. If you are still having trouble, it is best to seek professional assistance.