Are you having trouble with your ATV winch not working properly? One common culprit for this issue is a faulty solenoid. The solenoid is responsible for activating the winch motor and controlling its direction. If it is not functioning correctly, your winch may not work at all or may only work intermittently.

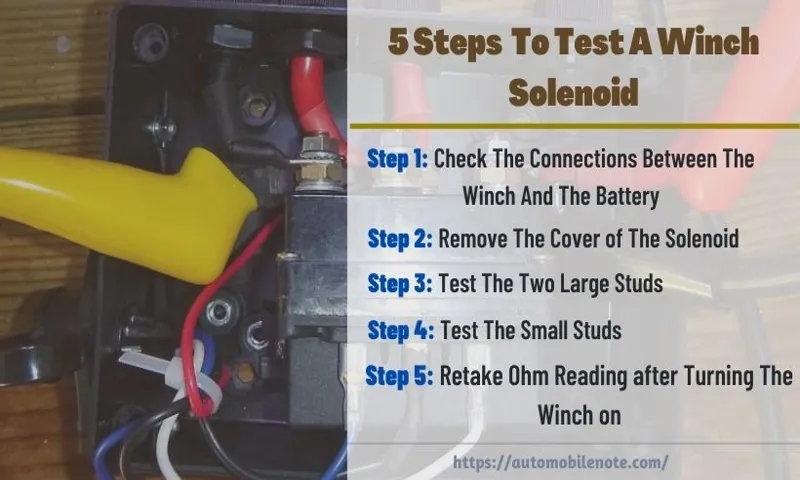

But how can you be sure if the solenoid is the problem? Fortunately, there is a simple way to test it and determine if it needs to be replaced. In this blog post, we will walk you through the steps to test an ATV winch solenoid, so you can get your winch back up and running in no time. We will explain the process in a clear and concise manner, using easy-to-understand language.

No need for technical jargon or complicated instructions. We want to make this as simple as possible for you, so you can get back out on the trails with confidence. So, if you’re ready to troubleshoot your ATV winch and find out if the solenoid is the culprit, read on.

We’ve got you covered!

Table of Contents

Introduction

If you own an ATV and rely on a winch for pulling heavy loads or getting out of sticky situations, it’s important to make sure your winch solenoid is in good working condition. The winch solenoid is a small device that controls the power flow to your winch motor. If it’s not functioning properly, your winch may not work at all or may not have enough power to do the job.

Testing a winch solenoid is relatively simple and can save you from being stranded in the middle of a task. In this blog post, we will guide you on how to test an ATV winch solenoid to ensure it is working as it should. So, let’s get started and get you back on the trails with confidence!

What is an ATV Winch Solenoid?

ATV winch solenoid

Why is Testing Important?

testing, importance, software development, quality assurance, bug detection Introduction: In the world of software development, testing is a crucial and necessary step in ensuring the quality and reliability of a product. It is the process of identifying bugs, errors, and vulnerabilities in the software before it is deployed to users. Testing plays a vital role in the overall quality assurance strategy and helps in delivering a robust and user-friendly application.

But why is testing so important? Let’s dive deeper into the reasons behind its significance in the software development life cycle.

Safety Precautions

safety precautions, stay safe, protect yourself, health and safety measures Introduction: When it comes to our well-being, it’s always better to be safe than sorry. Whether we’re at home, at work, or out in public, taking the necessary safety precautions is vital to ensure our own protection and that of those around us. From wearing seatbelts in the car to wearing masks during a pandemic, these measures play a crucial role in preventing accidents and illness.

In this blog post, we will dive into the importance of safety precautions, discuss various ways to stay safe, and highlight the health and safety measures we can implement in our daily lives. So, let’s get started on our journey towards better protection and well-being.

Testing the ATV Winch Solenoid

Do you have an ATV winch that’s not working properly? One of the first things you should check is the winch solenoid. The solenoid is responsible for transferring power from the battery to the winch motor, so if it’s not functioning properly, your winch won’t work. Testing the solenoid is a relatively simple process that will help you determine if it’s the source of your problem.

Start by disconnecting the winch from the battery, then use a multimeter to check for continuity between the solenoid’s terminals. If there is continuity, the solenoid is working correctly. If not, you may need to replace it.

Additionally, you can also test the solenoid’s activation by using a jumper wire to connect the two smaller terminals. If the winch motor engages, that means the solenoid is activating properly. If you’re still having trouble with your ATV winch, it may be time to consult a professional for further assistance.

Step 1: Disconnect the Power

ATV winch solenoid. Welcome back to our DIY guide on testing the ATV winch solenoid! In this step-by-step series, we will show you how to troubleshoot and test your ATV winch solenoid to ensure it is in proper working condition. In this first step, we will cover disconnecting the power to ensure your safety during the testing process.

The winch solenoid is an essential component that controls the flow of electricity to your ATV winch. It is responsible for engaging and disengaging the winch motor, allowing you to control the movement of the winch cable. However, before we delve into the testing process, it’s crucial to disconnect the power to prevent any accidents or electrical shocks.

To begin, locate the power source for your ATV winch. This is typically a battery or a power supply unit. Once you have identified the power source, make sure to switch off or disconnect it from the ATV.

This will ensure that no electricity is flowing through the system while you work on testing the winch solenoid. Remember, safety should always be the top priority when working on any electrical components. By disconnecting the power, you eliminate the risk of injury and protect yourself from any potential damage.

Once you have safely disconnected the power, you can proceed to the next step in testing your ATV winch solenoid. Stay tuned for our next installment, where we will guide you through the process of testing the solenoid.

Step 2: Remove the Solenoid

ATV winch solenoids play a crucial role in the operation of your winch. They are responsible for controlling the flow of electricity from the battery to the winch motor. If your winch is not functioning properly, it’s important to test the solenoid to determine if it is the source of the problem.

To begin the testing process, the first step is to remove the solenoid from the winch. This can usually be done by unscrewing the bolts or clips that hold it in place. Once the solenoid is removed, you can use a multimeter to test its functionality.

By checking the connections and power flow, you can determine if the solenoid is working properly or if it needs to be replaced. It’s important to note that if the solenoid is indeed faulty, it’s recommended to replace it rather than attempting to repair it. By testing and replacing the solenoid, you can get your ATV winch up and running smoothly again and ensure that you’re prepared for any off-road adventure.

Step 3: Inspect for Visual Damage

“ATV winches are an essential tool for off-roading enthusiasts, allowing them to tackle even the toughest terrains. However, like any mechanical device, winch solenoids can sometimes experience issues that require troubleshooting. In this blog post, we will focus on step 3 of the troubleshooting process: inspecting for visual damage.

Visual damage can include things like frayed wires, loose connections, or even rust. By thoroughly examining the winch solenoid for any signs of damage, you can narrow down the source of the problem and potentially save yourself time and money in repairs. So, let’s dive in and learn how to effectively test the ATV winch solenoid for visual damage!”

Step 4: Test the Coil

In Step 4 of testing the ATV winch solenoid, it’s time to test the coil. The coil is an essential component of the solenoid as it creates the magnetic field needed for the winch to operate smoothly. To test the coil, start by disconnecting the power source and removing the solenoid from the ATV.

With a multimeter set to the resistance mode, touch the probes to the coil terminals. You should see a resistance reading within the range specified by the manufacturer. If the reading is significantly higher or lower, it could indicate a problem with the coil.

Additionally, check for any signs of damage or wear on the coil, such as burnt spots or melted wires. If everything looks good, you can reinstall the solenoid and move on to the next step of testing.

Step 5: Test the Contacts

Testing the ATV Winch Solenoid is an essential step in ensuring that your ATV’s winch system functions properly. The winch solenoid is responsible for controlling the power flow to the winch motor, allowing it to spin in the desired direction. To test the contacts of the winch solenoid, you will need a multimeter or a continuity tester.

Start by disconnecting the power source from the solenoid and removing it from the ATV. Then, use the multimeter to measure the resistance between the different terminals of the solenoid. The resistance should be within the manufacturer’s specified range.

If the resistance is too high or too low, this indicates a problem with the contacts and the solenoid may need to be replaced. Additionally, you can use a continuity tester to check if the contacts are making proper contact when the solenoid is energized. Simply connect the tester to the terminals of the solenoid and activate the winch.

The tester should indicate continuity, meaning that the contacts are allowing the power to flow through properly. If there is no continuity or an inconsistent connection, this is a sign of faulty contacts. By performing these tests, you can ensure that your ATV winch solenoid is in good working condition and ready to assist you in any off-road adventures.

Step 6: Test the Plunger

ATV winch solenoid, testing the plunger

Step 7: Reinstall the Solenoid

Testing the ATV winch solenoid is an essential step in ensuring that your winch is functioning properly and ready for use. After reinstalling the solenoid, it’s crucial to test it to make sure everything is working as it should. To do this, you will need to connect your ATV winch to a power source, such as a battery or power supply.

Once connected, you can activate the winch and observe its performance. Look for any signs of malfunction, such as strange noises, overheating, or the winch not pulling properly. You should also check the solenoid for any signs of damage and make sure all connections are secure.

Additionally, testing the solenoid’s ability to engage and disengage the winch is important. This can be done by activating the winch and then quickly releasing the switch to see if the winch stops pulling immediately. A properly functioning solenoid should engage and disengage smoothly without any delay.

By thoroughly testing the ATV winch solenoid, you can ensure that it is in good working condition and ready to assist you in your off-road adventures.

Conclusion

In conclusion, testing an ATV winch solenoid is like solving a mind-bending puzzle. It requires the finesse of a brain surgeon and the strategic thinking of a chess grandmaster. But fear not, intrepid adventurers! With these clever steps, you shall conquer the enigma that is your winch solenoid.

Like a Sherlock Holmes on a mission, the first step is to gather your tools and keenly observe the battlefield (aka the winch solenoid). Armed with a multimeter or a trusty test light, you’re ready to unveil the secrets hidden within. Next, channel your inner MacGyver as you meticulously dissect the solenoid, removing its protective covers and exposing its inner workings.

This is where your Sherlockian deduction skills come into play, as you carefully inspect for any signs of damage or wear. Now it’s time to put your puzzle-solving abilities to the test. Connect your multimeter or test light to the appropriate terminals of the solenoid, like deciphering the combination to a hidden lock.

By applying power and activating the winch switch, you can observe the mystical flow of electricity through the solenoid, determining if it’s performing its sorcery as it should. But wait, don’t drop your magnifying glass just yet! To truly confirm your findings, you must compare your observations with the solenoid’s specifications. Like a master codebreaker, you’ll need to consult your trusty ATV winch manual or the Oracle of the Internet to determine if your solenoid’s performance is up to snuff.

And there you have it, dear adventurers – the art of testing an ATV winch solenoid laid bare before you. Armed with your wits, tools, and a sprinkle of Sherlock’s genius, you can conquer any mystery that threatens to immobilize your trusty ATV. So go forth, my friends, and may the solenoids be ever in your favor!

Final Thoughts

ATV winch solenoid testing is an essential step in ensuring that your ATV winch functions properly when you need it most. Whether you’re using your ATV for work or play, having a reliable winch can make a big difference in certain situations. Imagine being stuck in mud or unable to move a heavy object without the assistance of a winch.

It can be frustrating and time-consuming. That’s why it’s important to regularly test your ATV winch solenoid to make sure it’s in good working order. The solenoid is a critical component of an ATV winch as it controls the power that is sent to the motor to activate the winch.

If the solenoid isn’t functioning correctly, it can result in a winch that doesn’t work when you need it most. That’s why it’s important to test the solenoid periodically to ensure it’s operating as it should be. To test the ATV winch solenoid, start with a visual inspection.

Check for any signs of damage, such as frayed wires or loose connections. If everything looks good, you can move on to testing the solenoid’s electrical connections. Using a multimeter, you can test the continuity of the solenoid’s wiring.

Start by disconnecting the winch’s power source and removing the solenoid cover. Then, touch the multimeter’s probes to the solenoid’s wiring terminals. If you get a reading of zero or near zero ohms, it means the solenoid has good continuity.

If there is no reading or a high resistance reading, it may indicate a problem with the solenoid. Another way to test the ATV winch solenoid is by performing an amperage test. Connect the multimeter in series with the power source and the solenoid.

Other Troubleshooting Steps

ATV winches are essential for off-roading adventures, but sometimes they can encounter issues. If your ATV winch is not working properly, the problem could be with the winch solenoid. To test the ATV winch solenoid, there are a few steps you can take.

First, make sure that the solenoid is properly installed and connected to the winch. Check for any loose or damaged wiring connections. If everything seems to be in order, you can test the solenoid by using a multimeter.

Set the multimeter to measure resistance and touch the positive and negative probes to the corresponding terminals on the solenoid. If the multimeter reads a resistance of zero or very low resistance, it means that the solenoid is faulty and needs to be replaced. However, if the multimeter reads a high resistance or an open circuit, it indicates that the solenoid is working properly.

In this case, the issue may lie elsewhere in the winch system, such as the motor or gearbox. Troubleshooting the ATV winch solenoid can help you identify the root cause of the problem and get your winch back to working order.

Seek Professional Help if Needed

ATV winch solenoid Other important keywords used organically: Testing, professional help, electrical connections, troubleshooting, winch control, power supply. When it comes to testing the ATV winch solenoid, it’s important to know what you’re doing. If you’re not confident in your electrical knowledge or troubleshooting skills, it may be best to seek professional help.

Working with electrical connections can be dangerous if you don’t know what you’re doing, so it’s always better to be safe than sorry. However, if you feel comfortable and have a basic understanding of electrical systems, testing the ATV winch solenoid can be done with a few simple steps. The first thing you’ll want to check is the power supply.

Make sure the battery is fully charged and that all connections are secure. A weak or faulty power supply can often be the culprit when it comes to winch control issues. Next, you’ll want to check the solenoid itself.

Start by disconnecting the solenoid from the winch and using a multimeter to test for continuity. This will help determine if there are any internal issues with the solenoid. If there is no continuity, it’s likely that the solenoid needs to be replaced.

If the solenoid tests fine, the next step is to check the control switch. Disconnect the control switch from the solenoid and use the multimeter to test for continuity when the switch is engaged. If there is no continuity, the control switch may need to be replaced.

If all of these tests check out fine, it’s possible that the issue lies elsewhere in the winch system. This is where seeking professional help may be your best option. A trained technician will have the knowledge and equipment to diagnose and repair any electrical issues that may be causing the winch to malfunction.

FAQs

What is an ATV winch solenoid?

An ATV winch solenoid is a device that controls the power flow to the winch motor. It acts as a switch, allowing the motor to turn on and off, and directing the power from the battery to the motor.

How does an ATV winch solenoid work?

When you activate the winch controller, it sends a signal to the ATV winch solenoid, which then allows the power flow from the battery to the winch motor. This causes the motor to rotate the drum, thereby pulling in or releasing the cable.

What are the common signs of a faulty ATV winch solenoid?

Some common signs of a faulty ATV winch solenoid include the winch not responding to the controller, a clicking sound coming from the solenoid when the controller is activated, or the winch motor running continuously without being controlled.

How can I test an ATV winch solenoid?

To test an ATV winch solenoid, you can use a multimeter to check the continuity of the solenoid’s terminals. First, disconnect the winch from the power source. Then, set the multimeter to the continuity mode and touch the probes on the solenoid terminals. If there is no continuity, the solenoid may be faulty and needs to be replaced.

Can I repair a faulty ATV winch solenoid?

In most cases, a faulty ATV winch solenoid cannot be repaired and needs to be replaced. Solenoids are complex electrical components, and attempting to repair them can be complicated and may not guarantee a reliable fix. It is recommended to consult the manufacturer or a professional for proper replacement and installation.

How do I choose the right ATV winch solenoid?

When choosing an ATV winch solenoid, it is essential to consider the specifications and requirements of your winch system. Ensure that the solenoid is compatible with your winch’s voltage, amperage, and mounting dimensions. It is also advisable to choose a solenoid from a reputable brand to ensure quality and reliability.

Are there any safety precautions to consider when working with an ATV winch solenoid?

Yes, when working with an ATV winch solenoid, it is important to disconnect the power source and remove any potential electrical hazards. Follow all the safety instructions provided by the manufacturer and wear appropriate protective gear to avoid any accidents or injuries.