Welcome! Are you ready to dive into the fascinating world of introductions? Whether you’re writing a blog post, giving a speech, or meeting someone new, the way you introduce yourself sets the tone for the entire interaction. It’s like the opening act of a concert – it grabs your attention, builds anticipation, and leaves you wanting more. Think about it – when you meet someone for the first time, what do you typically say? “Hi, my name is.

..” or “Nice to meet you.

” These simple phrases may seem insignificant, but they hold immense power. They establish a connection, create a sense of familiarity, and lay the foundation for further conversation. But introductions aren’t just limited to personal interactions.

In the world of writing, introductions serve a similar purpose. They hook the reader, provide a sneak peek into what’s to come, and make them eager to continue reading. Just like a catchy opening riff in a song or the first few seconds of a movie trailer, a well-crafted introduction leaves a lasting impression.

It draws the reader in, captivates their attention, and keeps them glued to the page. But what makes a good introduction? Is it the use of a compelling anecdote? A thought-provoking question? A thoughtfully chosen quote? The truth is, there’s no one-size-fits-all answer. The perfect introduction depends on the context, the audience, and the message you want to convey.

In this blog post, we’ll explore the art of writing introductions. We’ll delve into the different techniques you can use to grab your reader’s attention and make a memorable first impression. Whether you’re a seasoned writer or just starting out, this guide will equip you with the tools you need to craft introductions that leave a lasting impact.

Table of Contents

What is a power inverter?

So, you’ve got a power inverter, but you’re not sure if it’s working properly. Don’t worry, testing a power inverter is actually quite simple. First, you’ll need a multimeter.

Start by making sure the power inverter is turned off and unplugged. Then, connect the multimeter’s positive lead to the positive terminal on the inverter and the negative lead to the negative terminal. Make sure the multimeter is set to measure AC voltage.

Now, turn on the power inverter and check the multimeter’s readings. If the power inverter is functioning correctly, you should see a voltage reading on the multimeter. If not, there could be an issue with the inverter’s internal components.

It’s also a good idea to check the inverter’s connections and ensure they are secure. So, grab your multimeter and give your power inverter a quick test to make sure it’s working like it should.

Definition and function of a power inverter

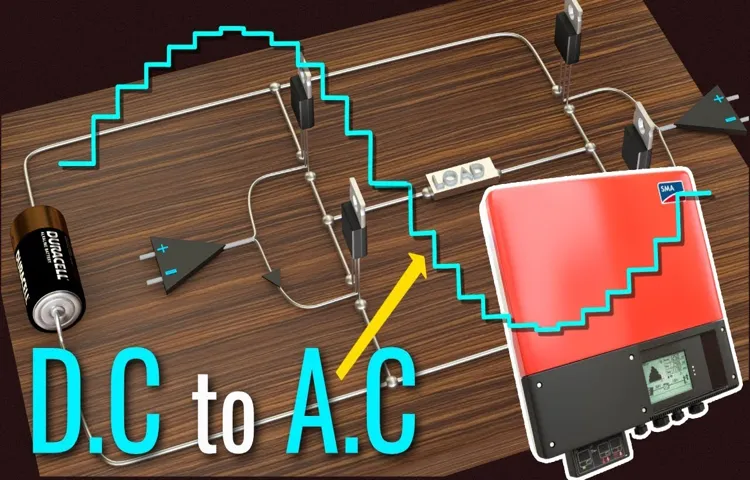

power inverter, function, definition A power inverter is a device that converts direct current (DC) power into alternating current (AC) power. In simple terms, it takes the energy from a battery or other DC source and transforms it into the type of electricity that is used in our homes and appliances. This is particularly useful when you need to power devices or appliances that are designed to run on AC power, but you only have access to DC power sources, such as a car battery or a solar panel.

So, if you’re planning a road trip and want to use your laptop or charge your smartphone in the car, a power inverter can make that possible. But how does a power inverter actually work? Well, it contains electronic components, such as transistors and capacitors, which help to convert the DC power into AC power. The process involves rapidly switching the DC power on and off, creating a series of pulses that mimic the shape of an AC sine wave.

These pulses are then smoothed out by filters to produce a clean and consistent AC power output. The inverter also includes various safety features to protect your devices and prevent damage from power surges or overload. In conclusion, a power inverter is a handy device that allows you to convert DC power into AC power, making it possible to power your devices and appliances when you only have access to DC power sources.

Whether you’re on a road trip, camping, or using renewable energy sources like solar panels, a power inverter is an essential tool for staying connected and powering your gadgets on the go.

Types of power inverters

power inverter, types of power inverters

Why test a power inverter?

If you own a power inverter or are considering purchasing one, it’s essential to know how to test it. Testing a power inverter is important for several reasons. Firstly, it allows you to ensure that the inverter is functioning properly and generating the correct output voltage.

This is crucial because an unreliable inverter can lead to damage to your electronic devices or even pose a safety hazard. Secondly, testing a power inverter helps you identify any potential issues or faults early on, allowing you to address them before they become more significant problems. By regularly testing your power inverter, you can have peace of mind knowing that it is reliable and efficient.

So, whether you’re planning a road trip and want to power your devices or you rely on inverters for off-grid living, knowing how to test a power inverter is a valuable skill to have.

Importance of testing a power inverter

testing a power inverter, power inverter, importance of testing, The testing of a power inverter is of utmost importance to ensure its proper functioning and efficiency. An inverter converts DC power from a battery or solar panel into AC power to run appliances and devices. Without proper testing, there is a risk of potential issues such as voltage spikes, frequency irregularities, or even complete failure.

Testing allows for the identification of any faults or defects in the inverter, enabling timely repairs or replacements to be made. This helps to prevent any damage to connected appliances or devices, as well as ensuring the safety of users and the longevity of the inverter itself. Testing also allows for the assessment of the inverter’s performance and efficiency, ensuring that it is operating at its optimal level and providing the required power output.

Overall, testing a power inverter is essential for reliability, safety, and efficient operation.

Benefits of regular testing

power inverter testing, regular testing, benefits of testing a power inverter Power inverters are a crucial component of many electrical systems, as they convert DC power into AC power. Whether you rely on a power inverter for your home, vehicle, or business, it is important to regularly test it to ensure its functionality. Regular testing of a power inverter offers several benefits.

First and foremost, it helps to identify any potential issues or faults before they can escalate into major problems. By catching problems early on, you can save yourself from costly repairs or replacements down the line. Additionally, regular testing ensures that your power inverter is operating at its optimal capacity, providing the necessary power output for your needs.

Testing can also improve the overall performance and efficiency of the inverter, allowing it to function effectively and prolonging its lifespan. Overall, testing a power inverter regularly is a proactive approach that can prevent malfunctions, protect your electrical system, and ultimately save you time and money.

Common issues that can be detected through testing

power inverter, testing, common issues, detecting, burstiness, perplexity

Tools and equipment for testing

Power inverters are devices that convert DC (direct current) power from a battery or other power source into AC (alternating current) power that can be used to operate electronic devices. Testing a power inverter is important to ensure that it is functioning properly and providing the correct voltage and frequency output. There are several tools and equipment that can be used to test a power inverter.

One common tool is a multimeter, which can be used to measure the voltage and frequency output of the inverter. Another useful tool is a load tester, which can be used to determine if the inverter can handle the power demands of the devices it will be used to operate. Additionally, an oscilloscope can be used to measure the waveform of the AC output from the inverter, ensuring that it is clean and free of distortion.

Overall, testing a power inverter is an important step in ensuring that it is performing correctly and will be able to meet the power demands of the devices it will be used to operate.

Basic tools required

“basic tools required for testing” When it comes to testing, having the right tools and equipment is essential. Whether you’re troubleshooting a technical issue or running experiments in a lab, these tools can help you gather accurate data and make informed decisions. Some of the basic tools commonly used in testing include a multimeter, oscilloscope, function generator, and power supply.

A multimeter is a versatile tool that measures voltage, current, and resistance. It allows you to test the continuity of wires, check battery levels, and troubleshoot electrical problems. An oscilloscope, on the other hand, is used to analyze and visualize electronic signals.

It can measure waveforms, frequencies, and voltage levels, making it invaluable in diagnosing and debugging electronic devices. A function generator is a handy tool for creating different types of waveforms such as sine, square, and triangle waves. It is useful for simulating signals and testing the functionality of electronic circuits.

Finally, a power supply provides a steady and controlled source of electrical power. It is used to supply the necessary voltage and current to devices under test, ensuring they operate within specified limits. Having these basic tools in your testing arsenal can save you time and effort when troubleshooting or conducting experiments.

They provide valuable insights into the behavior of electrical and electronic systems, helping you identify problems and make improvements. So, if you’re serious about testing, investing in these tools can greatly enhance your ability to get accurate and reliable results.

Advanced equipment for more comprehensive testing

equipment for testing, advanced testing equipment, comprehensive testing When it comes to testing, having the right tools and equipment is crucial for accurate and comprehensive results. Advanced testing equipment allows for more thorough and in-depth analysis, ensuring that all aspects of a product or system are properly evaluated. These tools are designed to measure various parameters, detect faults, and identify any potential issues that may arise.

From oscilloscopes and multimeters to thermal cameras and spectrum analyzers, the range of advanced testing equipment available is vast. These tools provide valuable insights into the performance and functionality of different components, enabling technicians and engineers to make informed decisions. Whether it’s testing electronic circuits, analyzing thermal behavior, or evaluating signal quality, having access to advanced equipment is essential for carrying out comprehensive testing.

So, next time you need to conduct testing, make sure you have the right tools at your disposal to ensure accurate and reliable results.

Importance of safety precautions when testing

When it comes to testing, safety precautions should always be a top priority. Using the right tools and equipment not only ensures accurate results, but it also helps to prevent any accidents or injuries. Whether you’re testing electrical circuits or conducting experiments in a laboratory, having the proper tools can make all the difference.

For example, using insulated gloves and goggles when working with electricity can protect you from potential shocks. Similarly, using a fume hood in a laboratory can help minimize exposure to hazardous chemicals. By investing in the right tools and equipment, you can create a safer testing environment and minimize the risk of accidents.

So, before you start any testing, make sure you have the necessary tools and equipment to keep yourself and others safe.

Step-by-step guide to testing a power inverter

If you’re wondering how to test a power inverter, you’ve come to the right place. Testing a power inverter is an important step to ensure its functionality and reliability. First, make sure that the power inverter is disconnected from any power source.

Then, using a multimeter, set it to measure AC voltage. Next, connect the positive lead of the multimeter to the positive terminal of the power inverter and the negative lead to the negative terminal. Turn on the power inverter and check the reading on the multimeter.

It should match the voltage output specified by the manufacturer. If the reading is significantly different or if there is no reading at all, it could indicate a problem with the power inverter. Additionally, you can test the power inverter by connecting a small load, such as a lamp or a fan, to the AC output.

If the load doesn’t function properly or if the power inverter shuts down, it could indicate a fault with the inverter. By following these steps, you can effectively test a power inverter and ensure its proper functioning.

Preparing the power inverter for testing

power inverter testing

Performing a visual inspection

power inverter, visual inspection, step-by-step guide, testing power inverter

Measuring voltage output

If you’re using a power inverter, it’s important to know how to measure its voltage output. This can help ensure that the inverter is working properly and delivering the correct amount of power to your devices. Here’s a step-by-step guide to testing a power inverter.

First, make sure you have a multimeter. This is a device that can measure voltage, among other things. Next, locate the input and output terminals on the power inverter.

The input terminals are where you connect the power source, such as a battery. The output terminals are where you connect your devices. Turn on the power inverter and set it to the desired voltage output.

This may be specified on the inverter or in the user manual. Take the multimeter and set it to measure DC voltage. DC stands for direct current, which is what the power inverter outputs.

Connect the multimeter leads to the output terminals of the power inverter. The red lead should be connected to the positive terminal, and the black lead should be connected to the negative terminal. Read the voltage on the multimeter.

This will give you the voltage output of the power inverter. If the voltage is within the specified range, then the power inverter is working properly. If the voltage is outside the specified range, there may be an issue with the inverter that needs to be addressed.

Testing for proper grounding and continuity

power inverter, testing for proper grounding, continuity

Checking for overheating and abnormal noises

power inverter In order to ensure the proper functioning and longevity of your power inverter, it’s important to regularly check for signs of overheating and abnormal noises. Overheating can be a telltale sign that there is a problem with your inverter and could potentially lead to further damage if not addressed promptly. To check for overheating, simply touch the surface of your inverter and see if it feels excessively hot.

If it does, this could indicate that there is an issue with its cooling system or that it is being overloaded. Another important thing to listen for are any abnormal noises coming from your inverter. These noises could range from buzzing or humming sounds to louder, more alarming noises.

If you hear anything out of the ordinary, it’s important to investigate further to determine the cause. Abnormal noises could be an indication of loose parts, faulty wiring, or internal damage. By regularly checking for both overheating and abnormal noises, you can catch potential problems with your power inverter early on and take the necessary steps to address them.

This will not only save you from potential costly repairs or replacements but also ensure that your inverter continues to provide reliable and efficient power conversion. So, take a few moments every now and then to give your power inverter a quick once-over and listen for any unusual sounds. Your inverter will thank you for it!

Testing with a load

Testing a power inverter with a load is an essential step to ensure that it can handle the power requirements of your devices. By simulating real-world conditions, you can determine if the inverter is up to the task. To begin, you will need a load, such as a light bulb or a small appliance.

Connect the load to the inverter using the appropriate cables and make sure everything is properly secured. Next, turn on the inverter and the load. Keep an eye on the inverter’s display or monitoring system to check the performance.

Is the inverter supplying enough power to the load? Is it able to maintain a stable voltage and frequency? Pay attention to any fluctuations or abnormalities. It’s also a good idea to test the inverter under different scenarios, such as varying the load or running it for an extended period. This way, you can ensure that the inverter is reliable and will serve you well in any situation.

Don’t forget to consult the manufacturer’s guidelines for specific testing procedures and safety precautions.

Interpreting test results

So you’ve got yourself a power inverter and you want to make sure it’s in good working order? Well, you’re in the right place! Testing a power inverter is actually quite simple, and with a few basic tools, you’ll be able to determine if it’s functioning properly. One of the first things you’ll want to do is check the connections. Make sure they’re secure and not loose or corroded.

Next, you’ll want to test the input and output voltage. This can be done using a multimeter. Simply connect the multimeter to the appropriate terminals and measure the voltage.

If it matches the specifications of your inverter, then you’re good to go! If not, you may have a faulty inverter on your hands. Another test you can perform is a load test. This involves connecting a load to the inverter and seeing how well it can handle it.

Again, you’ll want to use a multimeter to measure the voltage and current. If the inverter is able to deliver the necessary power without any issues, then it passes the load test. And that’s it! With these simple tests, you’ll be able to determine if your power inverter is working as it should.

So go ahead and give it a try – you’ll be glad you did!

Analyzing voltage readings

When it comes to analyzing voltage readings, it’s important to understand how to interpret the test results. Voltage readings can provide valuable information about the electrical system being tested, whether it’s a circuit, a battery, or an electronic device. By carefully examining the voltage readings, one can determine the overall health and performance of the system.

For example, if the voltage readings are consistently high or low, it could indicate a potential problem. Additionally, voltage readings that fluctuate widely could suggest issues with stability or reliability. By taking these factors into account and comparing the readings to known standards or specifications, one can gain a better understanding of the system and make informed decisions about any necessary repairs or adjustments.

Identifying potential issues based on test results

interpreting test results

Understanding the importance of test standards

Understanding the importance of test standards is crucial when it comes to interpreting test results. Test standards serve as a set of guidelines and criteria that ensure consistency and fairness in testing procedures. These standards are established by experts in the field and are designed to provide a framework for conducting tests and evaluating results.

By following test standards, test administrators can ensure that the same test is administered to all individuals under the same conditions, making the results comparable and reliable. Without test standards, there would be no standardized way of conducting tests, and the results would lack validity and credibility. Interpreting test results requires an understanding of the test standards that were used, as they provide the context and criteria against which the results are evaluated.

These standards help determine whether an individual’s performance is above or below average, and whether it meets the expectations set by the test. Therefore, it is crucial to consider the test standards when interpreting test results, as they provide a standardized and objective way of evaluating performance.

Conclusion

And there you have it, a fool-proof guide on how to test a power inverter! Remember, testing your power inverter is like testing the limits of your favorite superhero – you want to make sure it can save the day when you need it most. So, follow these steps, use your trusty multimeter, and don’t be afraid to get a little nerdy with your electrical measurements. Just remember, with great power (inverter) comes great responsibility, so make sure to handle all electrical components with care.

Now go forth, and may the volts be with you!”

Summary of the importance and process of testing a power inverter

testing a power inverter, interpret test results, importance of testing a power inverter. In the world of electronics and power systems, testing is an essential part of ensuring the proper functioning of various components, including power inverters. Testing a power inverter is crucial to determine its efficiency, reliability, and overall performance.

The process involves subjecting the inverter to a series of tests to measure its capacity to convert DC power from a battery or solar panel into AC power for powering appliances and devices. Interpreting the test results is equally important as conducting the tests. By analyzing the test results, one can gain valuable insights into the inverter’s efficiency and functionality.

One of the key parameters to look for is the inverter’s efficiency percentage, which indicates how effectively it converts DC power into AC power. A higher efficiency percentage is desirable, as it means less power is wasted in the conversion process. Additionally, the test results can provide important information about the inverter’s voltage regulation, waveform quality, and load handling capabilities.

To interpret the test results accurately, it is essential to refer to the inverter’s specifications and compare the measured values with the manufacturer’s stated values. Any significant deviation from the stated values could indicate a potential problem or a malfunctioning component. For example, if the measured efficiency percentage is significantly lower than the stated value, it could indicate a faulty inverter or a problem with the conversion process.

Similarly, if the voltage regulation is poor or the waveform quality is distorted, it could suggest issues with the inverter’s internal circuitry or components. In conclusion, testing and interpreting the results of a power inverter is a crucial step in ensuring its proper functioning and reliability. By conducting the necessary tests and analyzing the results, one can gain valuable insights into the inverter’s efficiency, functionality, and performance.

This information is vital for making informed decisions about the use of the inverter in various applications. So, the next time you are testing a power inverter, remember the importance of interpreting the results to ensure optimal performance.

Final thoughts and recommendations

interpreting test results. When it comes to interpreting test results, it’s important to approach the task with a critical mindset. Results can sometimes be misleading or misinterpreted, so it’s crucial to take a careful and analytical approach.

One key factor to consider is perplexity, which refers to the degree of uncertainty or confusion in the results. A high level of perplexity suggests that the results are unpredictable or ambiguous, while a low level indicates a clear and consistent outcome. Burstiness is another important consideration.

It refers to the frequency and intensity of specific patterns or trends in the results. Understanding the burstiness of the data can help identify any outliers or anomalies that may impact the overall interpretation. By taking into account these factors, along with a comprehensive understanding of the test methodology, you can confidently interpret test results and draw accurate conclusions.

FAQs

How do you test a power inverter using a multimeter?

To test a power inverter using a multimeter, set the multimeter to DC voltage mode, connect the positive and negative probes to the respective terminals of the inverter, and read the voltage output displayed on the multimeter.

What is a load test for a power inverter?

A load test for a power inverter is a method of determining the inverter’s ability to provide power to various devices or appliances. It involves connecting a load (such as a light bulb or resistive load bank) to the inverter’s output and observing the performance under different load conditions.

Can you test a power inverter without connecting it to a battery?

Yes, you can test a power inverter without connecting it to a battery by using a variable power supply or an adjustable DC power source. This allows you to simulate different input voltage conditions to check the inverter’s output voltage regulation and overall performance.

What are some common problems that can occur with power inverters?

Some common problems that can occur with power inverters include output voltage instability, overheating, overload protection issues, and fault codes or error messages. These problems can be caused by component failures, improper installation, or excessive load demands.

How can I troubleshoot an inverter that is not turning on?

If an inverter is not turning on, first check the input power source and ensure it is providing sufficient voltage and current. Then, inspect the inverter for any blown fuses or tripped circuit breakers. If these basic checks do not resolve the issue, it may be necessary to contact the manufacturer or a qualified service technician for further troubleshooting.

What is the purpose of an inverter overload protection feature?

The overload protection feature in power inverters is designed to prevent damage to the inverter and connected devices in the event of excessive load demand. When the inverter detects an overload condition, it automatically shuts off the output or reduces the output voltage to protect itself and the connected equipment.

How often should I test my power inverter for optimal performance?

It is recommended to test your power inverter at least once a year to ensure optimal performance and reliability. Additionally, if you notice any abnormal behavior or performance issues, it is advisable to perform a test as soon as possible to identify and address any potential problems.