If you are an ATV owner, you know the importance of having a reliable winch. Whether you use your ATV for work or play, a winch can be a lifesaver in sticky situations. But what happens when your winch stops working? One common culprit could be a faulty contactor.

The contactor is an essential component of your ATV winch that controls the flow of electricity to the motor. When the contactor fails, it can prevent your winch from functioning properly. So how do you test an ATV winch contactor to determine if it’s the source of the problem? In this guide, we’ll walk you through the steps to diagnose and troubleshoot your winch contactor.

By following these simple instructions, you can get your winch back in working order and get back to enjoying your ATV adventures. So let’s dive in and learn how to test an ATV winch contactor.

Table of Contents

Introduction

If you’re an ATV owner, chances are you’ve encountered a situation where you needed to use the winch to pull yourself out of a tight spot. The winch contactor is an essential component of the winch system, responsible for activating the motor and controlling the pulling power. It’s important to regularly test the winch contactor to ensure it’s functioning correctly to avoid any unexpected failures when you need it the most.

But how do you test the ATV winch contactor? In this blog section, we’ll walk you through a step-by-step guide on how to test your ATV winch contactor to ensure optimal performance whenever you need it.

What is an ATV winch contactor?

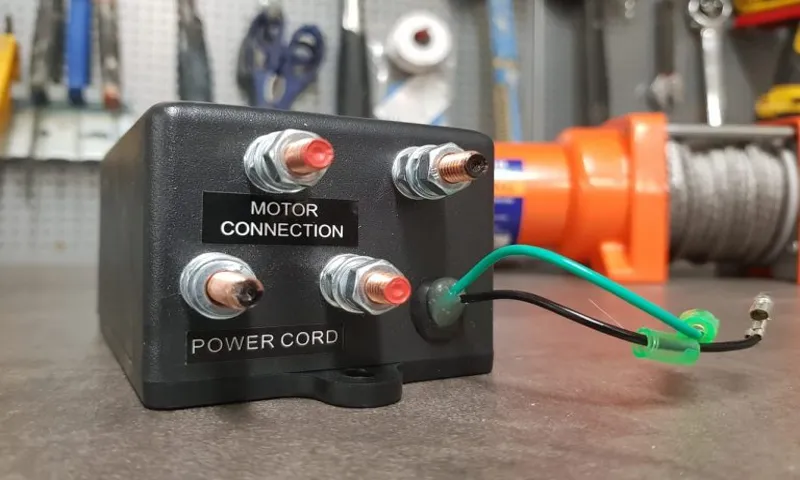

What is an ATV winch contactor? An ATV winch contactor is an essential component of an ATV winch system that helps control the electric power going to the winch. It acts like a switch, allowing the user to control the operation of the winch conveniently. When you press the winch control buttons on your ATV’s handlebars, the contactor is responsible for sending the necessary signals to the winch motor, directing it to either wind in or wind out the cable.

It ensures that the winch operates smoothly and efficiently, allowing you to easily pull yourself out of tough situations or help others in need.

Importance of testing the contactor

importance of testing the contactor

Tools and equipment needed

When it comes to testing an ATV winch contactor, there are a few tools and equipment that you will need. Firstly, you will need a multimeter. This is essential for measuring the electrical continuity of the contactor.

You will also need a set of jumper cables. These will be used to connect the contactor to a power source for testing. Additionally, a power source, such as a car battery or a power supply, will be required to provide the necessary voltage for the test.

Finally, it is helpful to have a set of electrical connectors and wire crimpers on hand to ensure secure connections during the testing process. By having these tools and equipment ready, you will be well-prepared to accurately test your ATV winch contactor and diagnose any potential issues.

Multimeter

multimeter, tools and equipment, electrical measurements, test electrical circuits, voltage, current, resistance, continuity, digital multimeter, analog multimeter, voltmeter, ammeter, ohmmeter, safety goggles, gloves, digital display, probes When it comes to working with electrical circuits, having the right tools and equipment is essential. One tool that every electrician or DIY enthusiast should have in their toolbox is a multimeter. A multimeter is a handheld device that is used to test electrical circuits and measure voltage, current, resistance, and continuity.

There are two types of multimeters available: digital multimeters and analog multimeters. Digital multimeters have a digital display, while analog multimeters have a needle and dial. To use a multimeter, you will need to have a pair of probes.

These probes can be used to measure the voltage across a circuit or to test for continuity. It is important to ensure that you are using the correct probes for the job to avoid any accidents. In addition to a multimeter and probes, it is also important to have some safety equipment on hand.

When working with electricity, it is crucial to protect yourself from potential hazards. This includes wearing safety goggles to protect your eyes from any flying debris, as well as gloves to protect your hands from electric shocks. In conclusion, a multimeter is a versatile tool that is essential for anyone working with electrical circuits.

Whether you are measuring voltage, current, resistance, or checking for continuity, a multimeter can provide you with accurate and reliable readings. Just remember to always use the appropriate probes and take the necessary safety precautions to protect yourself from any potential hazards. With the right tools and equipment, you can confidently tackle any electrical project.

So, make sure to include a multimeter in your toolbox!

Wire strippers

wire strippers, tools and equipment needed

Test leads

test leads, tools and equipment, electrical testing, multimeter, alligator clips, probes

Step-by-step guide to testing the contactor

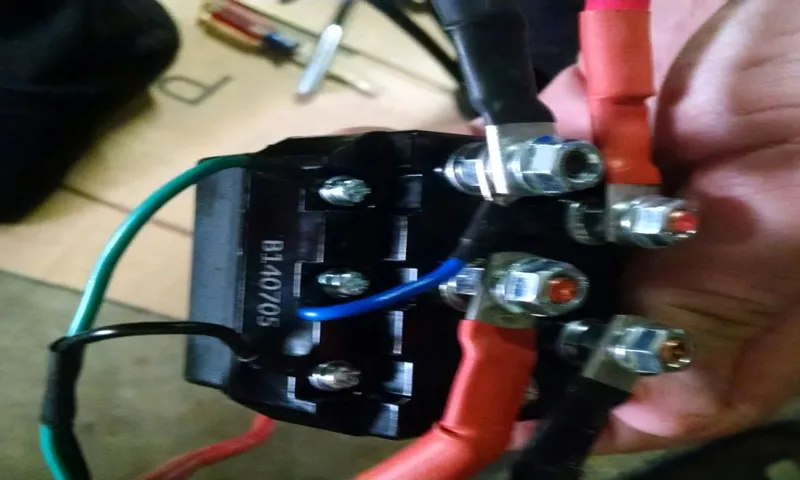

If you have an ATV winch and you suspect that the contactor is not functioning properly, it’s important to test it before going out on your next off-road adventure. Testing the contactor is a straightforward process that can be done with a few basic tools. First, make sure the winch is disconnected from any power source.

Then, remove the contactor cover to expose the terminals inside. Use a multimeter to check for voltage across the main power terminals. If there is no voltage, the contactor may be faulty and will need to be replaced.

If there is voltage, you can test the contactor by applying power to the control terminals using a jumper wire. If the winch motor engages and runs properly, the contactor is working correctly. However, if the motor does not engage or runs inconsistently, the contactor may need to be replaced.

By following these steps, you can ensure that your ATV winch contactor is in good working order and ready to assist you on your next off-road adventure.

Step 1: Safety precautions

When testing a contactor, it is essential to prioritize safety precautions to prevent any accidents or injuries. First, make sure to disconnect the power source to the equipment you are working on. This will ensure that you don’t accidentally come into contact with any live electrical wires.

Additionally, wearing personal protective equipment such as gloves, safety glasses, and insulated tools will provide an extra layer of protection. Before testing the contactor, it is crucial to thoroughly inspect it for any signs of damage or wear. Look for any burnt or melted parts, loose connections, or signs of corrosion.

If any defects are found, it is important to repair or replace the contactor before proceeding with the testing. Taking these safety precautions will help ensure a safe and successful testing process.

Step 2: Disconnect the power

contactor, power, electrical system, testing, disconnect, steps, guide, safety precautions. In order to safely test a contactor, it’s important to start by disconnecting the power. This step is crucial to avoid any potential accidents or electrical shocks.

Remember, safety should always be the top priority when dealing with electrical systems. Before disconnecting the power, make sure to turn off any associated breakers or switches that control the contactor. This will ensure that there is no power flowing to the contactor and minimize the risk of an electrical mishap.

Once you have confirmed that the power is off, you can proceed with testing the contactor. Taking these precautionary steps will not only protect you from harm but also ensure a smooth and efficient testing process.

Step 3: Locate the contactor

When troubleshooting an HVAC system, locating the contactor is an important step. The contactor is a vital component that controls the electrical flow to the compressor and condenser fan. It essentially switches the power on and off to these components.

To find the contactor, start by removing the access panel on the condenser unit. The contactor is typically a small rectangular box with multiple electrical terminals. It may be located near the bottom or side of the unit.

Once you’ve located the contactor, it’s time to move on to the next step in testing it.

Step 4: Inspect the contactor for damage

In order to properly test a contactor, one must thoroughly inspect it for any signs of damage. This step is crucial, as damaged contactors can pose serious safety risks and may not function properly. To inspect the contactor, start by visually examining it for any obvious signs of damage such as cracks, burnt marks, or melted parts.

Next, check the contacts themselves for any signs of wear or pitting. These can indicate that the contactor is not making proper electrical connections. Additionally, check the coil for any signs of overheating, such as discoloration or a burning smell.

If any damage is found, it is important to either repair or replace the contactor before continuing with the testing process. By thoroughly inspecting the contactor, you can ensure that it is in proper working order and ready for further testing.

Step 5: Test for continuity

When testing a contactor, one crucial step is to check for continuity. Continuity refers to the flow of electric current through a closed circuit. To test for continuity, you will need a multimeter, which is a handy tool for measuring electrical properties.

First, make sure the power is turned off before performing any tests. Then, set the multimeter to the continuity mode. Next, place one probe on the contactor’s input terminal and the other probe on the output terminal.

If the contactor is functioning properly, the multimeter will emit a beeping sound or display a reading close to zero ohms, indicating that there is continuity in the circuit. However, if the multimeter does not beep or shows a reading of infinity, there is no continuity, suggesting that the contactor may be faulty and needs to be replaced. Testing for continuity helps ensure that the contactor is working correctly and will effectively complete the electrical circuit it is responsible for.

Step 6: Test for voltage

In order to test for voltage in a contactor, you will need a multimeter. This handy tool allows you to measure the electrical potential difference between two points in an electrical circuit. Start by turning off the power to the contactor and make sure all the electrical connections are secure.

Then, set your multimeter to the voltage setting and attach the red probe to the contactor’s load side terminal. Next, attach the black probe to ground, such as a metal surface or the neutral terminal. Once your probes are in place, turn the power back on and carefully observe the reading on your multimeter.

A reading of zero volts means there is no voltage present, while a reading above zero volts indicates the presence of voltage. Remember to be cautious and follow safety precautions when dealing with electrical circuits, as they can be dangerous.

Common problems and solutions

Testing an ATV winch contactor is essential to ensure that it is functioning properly. There are a few common problems that can arise with an ATV winch contactor, such as a lack of power, failure to engage or disengage, or a burnt-out solenoid. To test the contactor, start by checking the power supply by using a multimeter to measure the voltage.

If there is no power, you may need to check the fuse or wiring connections. Next, check the engagement and disengagement of the contactor by applying power and checking for movement. If it fails to engage or disengage, the solenoid may be faulty and need to be replaced.

Finally, test the solenoid by checking for continuity using a multimeter. If it does not have continuity, it will need to be replaced. By following these steps, you can effectively troubleshoot and test an ATV winch contactor to ensure its proper functioning.

Problem: Contact stuck in the closed position

Contact stuck in the closed position

Solution: Cleaning or replacing the contactor

contactor replacement, cleaning contactor, common HVAC problems, HVAC maintenance If your HVAC system is experiencing issues, such as frequent circuit break trips or the system not turning on at all, a common culprit could be a dirty or malfunctioning contactor. The contactor is an electrical switch that controls the flow of electricity to the compressor and fan motor in your air conditioning unit. Over time, the contactor can become covered in dirt, dust, and debris, which can prevent it from working properly.

In some cases, the contactor may need to be replaced if it is damaged or worn out. To solve this problem, you can start by cleaning the contactor with a soft brush or compressed air to remove any buildup. If the contactor is severely damaged or not functioning correctly after cleaning, it may be necessary to replace it.

By performing regular maintenance on your HVAC system and addressing any issues early on, you can prevent more significant problems from occurring and ensure that your system operates efficiently.

Problem: Contact not closing properly

contact closing, troubleshooting, common problems, solutions Have you ever experienced the frustration of a contact that just won’t close properly? You press the button, but nothing happens, or the contact doesn’t fully connect. It’s a common problem that many people face, but luckily, there are a few solutions to try. One possible issue is that there could be debris or dirt trapped within the contact, preventing it from making a solid connection.

Try cleaning the contact with a soft cloth or compressed air to remove any obstructions. Another potential culprit could be a loose wire inside the contact, causing it to not stay closed. In this case, you may need to tighten the screws or seek professional assistance to fix the issue.

In some instances, the contact itself may be faulty and need to be replaced. By troubleshooting and applying these solutions, you can ensure that your contacts close properly and function as intended.

Solution: Adjusting the contactor or replacing it

If you’re experiencing issues with your HVAC system not turning on or turning off unexpectedly, one of the common culprits could be a faulty contactor. The contactor is an electrical switch that controls the flow of electricity to the compressor, fan motor, and other components of the HVAC system. Over time, the contactor can become worn out or misaligned, causing it to not make proper contact and preventing the system from functioning correctly.

To fix this issue, you can try adjusting the contactor by tightening any loose screws and ensuring it is properly aligned. If that doesn’t solve the problem, it may be necessary to replace the contactor altogether. Replacing a contactor is a relatively simple and inexpensive fix that can restore your HVAC system to full functionality.

It’s always a good idea to consult with a professional HVAC technician to diagnose and address any issues with your system.

Problem: No power to the contactor

One common problem that can occur with a contactor is a lack of power reaching it. This can happen for a variety of reasons, but one possible cause is a tripped circuit breaker. If the breaker connected to the contactor has tripped, it can cut off power to the device.

In this case, the solution would be to reset the breaker and restore power. Another potential issue could be a fault in the wiring. If there is a short circuit or a loose connection somewhere in the wiring leading to the contactor, it can disrupt the flow of electricity and prevent power from reaching the device.

In this scenario, it would be necessary to inspect the wiring and make any necessary repairs or replacements. Finally, it is also possible that the contactor itself is faulty. Over time, contactors can wear out or become damaged, which can prevent them from receiving power.

If this is the case, the contactor may need to be replaced with a new one. It is important to diagnose the underlying cause of the power issue before attempting any repairs or replacements to ensure a proper and effective solution.

Solution: Checking the wiring or battery connection

One of the most common problems when it comes to electronic devices is a malfunctioning or faulty wiring connection. It can happen due to a loose connection or a damaged wire. This can often lead to the device not working properly or not turning on at all.

Luckily, checking the wiring or battery connection is a relatively simple solution to this issue. Start by inspecting the wires and connections to see if there are any visible signs of damage or loose connections. If everything looks fine, you can try disconnecting and reconnecting the wires to ensure a secure connection.

Additionally, if your device has a battery, make sure it is properly inserted and connected. By taking these steps, you can quickly resolve any issues related to wiring or battery connections and get your device back up and running smoothly.

Conclusion

So, there you have it! Testing your ATV winch contactor doesn’t have to be a daunting task. By following these simple steps, you can ensure that your winch is in proper working order and ready to tackle any tough situation on the trail. Remember, a winch is only as good as its contactor, so it’s crucial to test and maintain this important component.

Whether you’re a seasoned off-roader or a newbie to the ATV world, taking the time to check your winch contactor will save you from being stuck and make you the hero of the day. Just remember to use your newfound winching powers for good and not evil! Now go forth and conquer the trails with confidence, knowing that your winch contactor has been thoroughly tested and is ready for action. Happy winching!”

Importance of regular contactor testing

contractor testing

Final tips for maintaining an ATV winch contactor

One common problem that ATV owners may encounter with their winch contactor is a lack of power. This can happen if the electrical connections become loose or corroded over time. To fix this, you can start by checking all the connections and tightening them if necessary.

If you notice any corrosion, you can use a wire brush to clean the affected areas. Another solution to this problem is to check the battery voltage and make sure it is not running low. If the battery is not providing enough power, it may need to be charged or replaced.

It’s also worth noting that using a winch for an extended period of time can drain the battery, so it’s important to keep an eye on the voltage and charge the battery as needed. Overall, by regularly inspecting and maintaining the electrical connections and battery, you can ensure that your ATV winch contactor continues to work effectively and provide the power you need.

FAQs

What is an ATV winch contactor and what is its purpose?

An ATV winch contactor is an electrical switch that controls the power flow to an ATV winch. Its purpose is to regulate the electrical current and provide a reliable connection between the winch motor and battery.

How does an ATV winch contactor work?

When the winch control switch is engaged, the ATV winch contactor receives a signal to close the circuit and allow electricity to flow from the battery to the winch motor. This activates the winch and allows it to pull or release the cable.

How do I know if my ATV winch contactor is faulty?

Signs of a faulty ATV winch contactor include a winch that doesn’t respond or only works intermittently, odd noises coming from the winch, or sparks when powering the winch. You can also use a multimeter to test the continuity and resistance of the contactor.

Can I replace an ATV winch contactor myself?

Yes, replacing an ATV winch contactor is relatively straightforward. Most contactors are designed to be plug-and-play, meaning you can disconnect the old one and connect the new one without any special tools or electrical knowledge. However, it’s always recommended to consult the manufacturer’s instructions or seek professional assistance if you are unsure.

How often should I test or inspect my ATV winch contactor?

It is a good practice to visually inspect your ATV winch contactor regularly for any signs of damage or wear. As for testing, you should test your winch contactor whenever you experience issues with your winch or during routine maintenance. It is also recommended to test it before heading out on a big off-road adventure to ensure it is functioning properly.

Can a faulty ATV winch contactor damage other components?

Yes, a faulty ATV winch contactor can potentially damage other components in the winch system if left unaddressed. For example, if the contactor is not regulating the electrical current correctly, it can cause the winch motor to overheat or burn out. Therefore, it’s important to detect and resolve any contactor issues promptly.

Are there any safety precautions I should take when working with an ATV winch contactor?

When working with an ATV winch contactor, always disconnect the power source (usually the battery) before performing any maintenance or replacement. Additionally, wearing appropriate safety gear such as gloves and safety glasses is recommended. It’s always best to follow the specific guidelines provided by the manufacturer for your particular ATV winch and contactor model.