Hey there! Are you excited to learn about the fascinating world of astrology? Well, you’ve come to the right place! In this blog, we’re going to dive deep into the realm of astrology and uncover its secrets. But first, let me ask you a question – have you ever wondered how the positions of the stars and planets can influence our lives? Astrology is an ancient practice that dates back thousands of years. It is based on the belief that the movements of celestial bodies can have a profound impact on our personalities, relationships, and even the events that occur in our lives.

It’s a captivating concept that has captured the imagination of people throughout history, from ancient civilizations to modern-day enthusiasts. Think of astrology as a cosmic map that guides us through life. Just like a map helps us navigate unfamiliar territory, astrology provides insights into our strengths, weaknesses, and potential challenges.

By understanding the positions of the celestial bodies at the time of our birth, we can gain a deeper understanding of ourselves and the world around us. To fully grasp the intricate workings of astrology, we need to explore its different aspects. We’ll delve into the twelve zodiac signs, each represented by a unique constellation, and discover their distinct characteristics and traits.

We’ll also explore the twelve houses of astrology, which govern different areas of our lives, such as relationships, career, and health. Throughout this blog, we’ll debunk misconceptions, provide practical tips, and explore the intricate connections between astrology and our everyday lives. So buckle up and get ready to embark on a cosmic journey like no other.

Let’s unlock the secrets of the stars and uncover the wisdom that astrology has to offer. Are you ready to start exploring the captivating world of astrology? Let’s dive in!

Table of Contents

- 1 What is an ATV Winch Solenoid?

- 2 Why Test the ATV Winch Solenoid?

- 3 Multimeter

- 4 Safety Equipment

- 5 Step 1: Turn Off the Power

- 6 Step 2: Locate the Solenoid

- 7 Step 3: Disconnect Wires

- 8 Step 4: Setting Up the Multimeter

- 9 Step 5: Testing the Solenoid Contacts

- 10 Step 6: Testing the Solenoid Coils

- 11 Step 7: Analyzing the Results

- 12 Summary of Testing Process

- 13 Next Steps

- 14 Conclusion

- 15 FAQs

What is an ATV Winch Solenoid?

An ATV winch solenoid is a crucial component of your ATV’s winch system. It acts as a switch, allowing the electrical current to flow to the winch motor and control its operation. It essentially functions as a relay, activating the winch when you engage the switch, and stopping it when you release the switch.

Testing an ATV winch solenoid with a multimeter is a relatively straightforward process that can help you diagnose any issues with your winch system. To begin, you’ll need a multimeter, a pair of test leads, and a basic understanding of how to use the multimeter. Start by disconnecting the winch solenoid from the power source and isolating it.

Then, set your multimeter to the ohms (Ω) setting. Attach one test lead to the positive terminal of the winch solenoid, and the other test lead to the negative terminal. Once you have your multimeter set up, you can test the winch solenoid by checking the resistance across the terminals.

A healthy winch solenoid should have a low resistance reading, typically around 1-2 ohms. If your multimeter shows an open circuit or a very high resistance reading, it indicates a faulty or damaged solenoid that needs to be replaced. Testing your ATV winch solenoid with a multimeter can help you troubleshoot any issues with your winch system and ensure it is functioning properly.

By following these simple steps, you can determine if your solenoid is working correctly or if it needs to be replaced for optimal performance.

Why Test the ATV Winch Solenoid?

If you’re an ATV enthusiast, you know that a winch is an essential tool for those tricky off-road situations. But what if your winch isn’t working properly? One potential culprit could be a faulty winch solenoid. The winch solenoid is responsible for controlling the flow of electrical current to the winch motor, so if it’s not working correctly, your winch won’t work either.

That’s why it’s important to know how to test your ATV winch solenoid with a multimeter. By using a multimeter to measure the resistance and voltage of the solenoid, you can determine if it’s functioning properly or if it needs to be replaced. So don’t let a malfunctioning winch ruin your next off-road adventure.

Take the time to test your ATV winch solenoid and ensure that it’s ready to help you tackle any terrain.

Hey there! Planning a project and wondering what materials you’ll need? Look no further! In this blog, we’ll cover everything you need to know about the materials needed for your next endeavor. Whether you’re taking on a DIY home improvement project or starting a creative craft, having the right materials on hand is essential for success. From tools and equipment to supplies and ingredients, we’ll break down the different categories of materials and provide some handy tips along the way.

So, let’s dive in and get you well-prepared for your next project, shall we?

Multimeter

If you’re having trouble with your ATV winch solenoid, you may need to test it with a multimeter. But how do you do that? Well, a multimeter is a versatile tool that can measure voltage, current, and resistance. To test your ATV winch solenoid, you’ll first want to make sure it’s disconnected from any power source.

Set your multimeter to the resistance or ohms setting, and then touch the red probe to one of the solenoid’s terminals and the black probe to the other terminal. If the multimeter reads a low resistance, typically zero or close to zero, it means that the solenoid is functioning properly. However, if the multimeter reads a high resistance or an open circuit, it means there is a problem with the solenoid and it may need to be replaced.

So, the next time you’re dealing with an ATV winch solenoid issue, grab your trusty multimeter and put it to the test!

Safety Equipment

If you’re having trouble with your ATV winch solenoid, one way to test it is with a multimeter. A multimeter is a handy tool that can measure various electrical properties, such as voltage, current, and resistance. To test the solenoid, you’ll need to set your multimeter to the appropriate setting for resistance, typically denoted by the omega symbol (Ω).

Start by disconnecting the solenoid from the power source and any other wires. Then, using the multimeter’s probes, touch one probe to each terminal of the solenoid. If the multimeter displays a resistance reading within the specified range for your solenoid, then it is functioning properly.

However, if the reading is infinite or significantly higher than the specified range, then the solenoid may be faulty and in need of replacement. Testing the ATV winch solenoid with a multimeter can help ensure that it is in good working condition and ready to assist you when you need it most.

Picture this: you’re out on a thrilling ATV adventure, conquering rocky terrains and muddy trails. Suddenly, disaster strikes and your ATV gets stuck. In that moment, you realize the importance of having a reliable winch to help you get out of a sticky situation.

But what happens when your winch fails to work properly? Here comes the hero of the story – the ATV winch solenoid. This small yet mighty device acts as the brain behind your winch’s operation, controlling its power and ensuring smooth functionality. In this blog, we will dive deep into the world of ATV winch solenoids, exploring their significance, common issues, and how to test them to keep your off-road adventures worry-free.

So buckle up and get ready to learn all about this unsung hero of the ATV world.

Step 1: Turn Off the Power

When it comes to testing an ATV winch solenoid with a multimeter, there are a few steps you need to follow to ensure your safety and the accuracy of the test. The first step is to turn off the power to the ATV. This is important because working with electrical components can be dangerous if the power is still on.

By turning off the power, you eliminate the risk of electrical shocks or short circuits. Once the power is off, you can proceed with the testing process. Keep in mind that it’s always a good idea to consult the user manual or seek professional advice if you’re unsure about any step of the process.

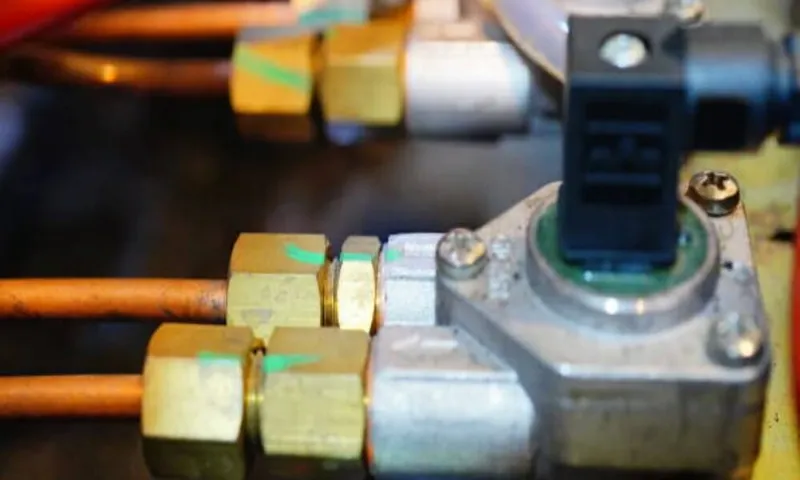

Step 2: Locate the Solenoid

One important step in testing an ATV winch solenoid with a multimeter is to locate the solenoid itself. The solenoid is a small device that is responsible for controlling the flow of electricity to the winch motor. It is usually located near the motor or on the winch control box.

To find the solenoid, you can follow the wires that connect to the winch motor. These wires will lead you to the solenoid. Once you have located the solenoid, you can proceed with testing it using a multimeter.

Step 3: Disconnect Wires

Now that you have located the winch solenoid in your ATV and identified the wires connected to it, it’s time to move on to the next step – disconnecting the wires. This step is crucial because it allows you to isolate the solenoid from the rest of the electrical system, ensuring an accurate measurement with your multimeter. To disconnect the wires, you will need to carefully remove the connectors or terminals that are attached to the solenoid.

Before doing so, it’s a good idea to take a picture or make a note of how the wires are connected, so that you can easily reassemble them later. Start by gently pulling the connectors or terminals away from the solenoid. You may need to use a small wrench or pliers to loosen any screws or nuts that are securing the wires in place.

Be sure to do this with caution, as you don’t want to damage the connectors or the solenoid itself. Once the wires are disconnected, you can move on to the next step of testing the winch solenoid with your multimeter. But before you do, take a moment to inspect the wires for any signs of damage, such as fraying or corrosion.

If you notice any issues, it’s best to replace the damaged wires before proceeding. Remember, safety should always be your top priority when working with electrical components. If you’re unsure about any step of the process or don’t feel comfortable doing it yourself, it’s always a good idea to seek the assistance of a professional.

After all, it’s better to be safe than sorry when it comes to your ATV’s electrical system.

Step 4: Setting Up the Multimeter

To test an ATV winch solenoid with a multimeter, you need to set up the multimeter properly. Here’s how you can do it: First, ensure that the multimeter is turned off. Then, connect the red probe of the multimeter to the positive terminal of the winch solenoid and the black probe to the negative terminal.

Next, turn on the multimeter and set it to the resistance or ohms function. This function is usually represented by the Greek letter omega or the word “ohms” on the dial. Make sure the multimeter is set to the appropriate range for the resistance you expect to measure.

Now, you’re ready to test the solenoid. Start by measuring the resistance across the solenoid’s coil terminals. Place the probes on the two coil terminals and note the reading on the multimeter.

A good solenoid would typically have a low resistance reading, usually around a few ohms. If the multimeter reads infinite resistance or open circuit, it indicates a faulty solenoid coil. On the other hand, if the multimeter reads zero resistance or a short circuit, it suggests a shorted coil.

Once you have tested the solenoid coil, you can also check the continuity of the switch terminals by placing one probe on the positive terminal and the other on the negative terminal. A good solenoid will show continuity, meaning the multimeter will beep or show a very low resistance reading. By setting up the multimeter correctly and following these steps, you can effectively test an ATV winch solenoid to determine if it is functioning properly or if it needs to be replaced.

Step 4.1: Set the Multimeter to Resistance (Ohms) Mode

The next step in setting up your multimeter is to switch it to the resistance mode, also known as ohms mode. This mode allows the multimeter to measure the resistance of a component or circuit. To set the multimeter to resistance mode, locate the dial or button on the multimeter that corresponds to this mode.

It is usually labeled with the Ω symbol, which represents ohms. Once you have found the right setting, turn the dial or press the button to select the resistance mode. The multimeter will now be ready to measure resistances.

By setting the multimeter to resistance mode, you can quickly and accurately determine the resistance of a circuit or component, which is crucial for troubleshooting electrical problems or testing the functionality of electronic devices. So, take a moment to familiarize yourself with the resistance mode on your multimeter, and get ready to measure ohms like a pro!

Step 4.2: Set the Multimeter to the Appropriate Range

Setting the multimeter to the appropriate range is an important step in using the device effectively. Different measurements require different ranges on the multimeter, so it’s essential to select the correct setting to obtain accurate readings. When choosing the range on the multimeter, you want to ensure that it is set higher than the value you are trying to measure.

This prevents the risk of damaging the multimeter or affecting the accuracy of the reading. For example, let’s say you are measuring the voltage of a battery. If the battery’s voltage is expected to be around 9 volts, you should set the multimeter to a range higher than 9 volts.

Setting it to a lower range could overload the multimeter and potentially damage it. On the other hand, if you set the multimeter to a range much higher than the expected voltage, you may not get an accurate reading. The measurement might appear as “overrange” or display incorrect values.

To determine the appropriate range, you can start with the highest range and work your way down if necessary. Most multimeters have an auto-range feature that automatically selects the correct range based on the measurement. However, it’s still helpful to have a general idea of the expected value to avoid potential issues.

Overall, setting the multimeter to the appropriate range is crucial for obtaining accurate measurements. By selecting a range higher than the value you are measuring, you can ensure the safety of the multimeter and achieve reliable results.

Step 5: Testing the Solenoid Contacts

When it comes to testing the solenoid contacts on your ATV winch, using a multimeter is the way to go. This handy tool can help you determine if there are any issues with the solenoid contacts, which are responsible for controlling the flow of electrical current to the winch motor. To begin, you’ll first need to disconnect the winch from the power source and remove the solenoid cover.

Then, set your multimeter to the continuity mode and touch one probe to each of the solenoid contact terminals. If you hear a beep or see a reading of zero ohms, this indicates that the contacts are in good working condition. However, if you don’t hear a beep or see a reading of infinity ohms, this means there is a problem with the contacts and they will need to be replaced.

By testing the solenoid contacts with a multimeter, you can ensure that your ATV winch is operating efficiently and ready for your next outdoor adventure.

Step 5.1: Touch the Multimeter Leads to the Solenoid Contacts

When it comes to testing the solenoid contacts, one important step is to touch the multimeter leads to the contacts themselves. This is where the real testing takes place, as we want to determine if there is continuity present in the solenoid. To do this, we take the two leads of the multimeter and touch them to the contacts of the solenoid.

It’s like connecting a puzzle piece, where the multimeter acts as the bridge between the two points. By doing this, we can see if there is a complete path for the electrical current to flow through. If there is continuity, then we know the solenoid contacts are working properly.

However, if there is no continuity, it suggests that there may be a problem and further troubleshooting is needed. This step is crucial because it helps us pinpoint the issue with the solenoid contacts. Whether it’s a loose connection or a faulty component, testing the contacts directly allows us to determine what needs to be fixed.

So, next time you’re testing solenoid contacts, be sure to touch the multimeter leads to the contacts and check for continuity. It’s a simple step that can provide valuable information about the health of your solenoid.

Step 5.2: Check the Multimeter Reading

In the previous steps, we learned how to test the solenoid contacts in our electromechanical device. Now let’s move on to the next step: checking the multimeter reading. This is an important step to make sure that our solenoid contacts are functioning properly.

To do this, we need to use a multimeter, which is a versatile tool used to measure electrical currents, voltages, and resistances. To check the multimeter reading, we first need to set the multimeter to the appropriate mode. Depending on the type of multimeter you have, you may need to select the resistance mode or the continuity mode.

Once the multimeter is set to the correct mode, we can proceed to test the solenoid contacts. To do this, we need to connect the multimeter leads to the terminals of the solenoid contacts. The red lead should be connected to the positive terminal, and the black lead should be connected to the negative terminal.

Now, we can activate the solenoid by applying a voltage to it. This can be done by briefly connecting a power source, such as a battery, to the solenoid terminals. As the solenoid activates, the contacts should close, allowing the current to flow through them.

With the solenoid activated, we can now check the multimeter reading. If the reading shows a low resistance or continuity, it means that the contacts are functioning properly and are making a good electrical connection. However, if the multimeter reading shows a high resistance or no continuity, it means that the contacts are not making a proper electrical connection and may need to be cleaned or replaced.

In conclusion, checking the multimeter reading is an essential step in testing the solenoid contacts. It helps us ensure that the contacts are functioning properly and are making a good electrical connection. By following the steps outlined above, we can confidently troubleshoot and repair any issues with the solenoid contacts in our device.

Step 6: Testing the Solenoid Coils

Now that we have checked the continuity of the wires in the ATV winch solenoid, it’s time to test the solenoid coils themselves. To do this, we will use a multimeter. A solenoid coil is an electrical component that converts electrical energy into mechanical work.

It consists of a coil of wire wound around a metal core. When current flows through the coil, a magnetic field is created, which then moves the metal core. This movement is what allows the solenoid to perform its intended function, such as engaging or disengaging the ATV winch.

To test the solenoid coils, start by setting your multimeter to the “Ohms” or resistance mode. Next, disconnect any power source from the ATV winch solenoid to prevent any accidents. Then, touch one probe of the multimeter to one terminal of the solenoid coil, and the other probe to the other terminal.

The multimeter should display a resistance reading. If it shows infinite resistance or does not display any reading at all, it means that the solenoid coil is open or faulty and needs to be replaced. On the other hand, if the multimeter displays a very low resistance reading (usually less than 5 ohms), it means that the solenoid coil is shorted or has a low resistance connection.

In this case, the solenoid coil is also faulty and needs to be replaced. Keep in mind that different solenoid coils may have different resistance values, so refer to the manufacturer’s specifications for the specific resistance range of the ATV winch solenoid coils you are testing. Testing the solenoid coils is an important step in troubleshooting any issues with your ATV winch.

By ensuring that the coils are in good working condition, you can be confident that your winch will function properly when you need it the most.

Step 6.1: Touch the Multimeter Leads to the Solenoid Coils

solenoid coil, multimeter, testing In this step of testing the solenoid coils, we will be using a multimeter to check for continuity. A multimeter is a versatile tool that measures various electrical properties, including resistance and continuity. By checking continuity, we can determine if there is a complete electrical circuit in the solenoid coil.

To begin, make sure that the multimeter is set to the continuity or ohms Ω mode. This mode allows the multimeter to measure the resistance of the solenoid coil. Once the multimeter is set, touch the leads (the two wires attached to the multimeter) to the two terminals of the solenoid coil.

As you touch the leads to the terminals, the multimeter will display a resistance value. A low resistance value indicates that there is continuity in the circuit, meaning that the solenoid coil is functioning correctly. On the other hand, a high resistance value or no reading at all indicates that there is a break in the circuit.

This means that the solenoid coil is faulty and needs to be replaced. By testing the solenoid coils using a multimeter, you can easily identify any issues and determine whether they can be fixed or if replacement is necessary. It is important to check both the primary and secondary coils, as either one can cause problems with the solenoid’s operation.

So, take your time and make sure to check both coils thoroughly.

Step 6.2: Check the Multimeter Reading

solenoid coils, multimeter reading Once you have connected the solenoid coils to the multimeter, it’s time to check the readings. The multimeter is a handy tool that measures electrical current, voltage, and resistance. By checking the multimeter reading, you can determine if the solenoid coils are functioning correctly.

To check the multimeter reading, set the multimeter to the appropriate setting for measuring resistance. Make sure the solenoid coils are disconnected from any power source before proceeding. Touch the probes of the multimeter to the two terminals of the solenoid coil.

The multimeter should display a reading in ohms, which indicates the resistance of the coil. If the multimeter reading is within the specified range for the solenoid coil, then it means the coil is functioning properly. The resistance value may vary depending on the specific coil and its design.

Refer to the manufacturer’s specifications or consult a professional if you are unsure about the acceptable range. On the other hand, if the multimeter reading shows no resistance or a value outside the specified range, it indicates a problem with the solenoid coil. This could be due to a faulty coil or a problem with the wiring.

In such cases, you may need to replace the coil or troubleshoot the wiring to identify and fix the issue. Remember, the multimeter reading is a crucial step in testing the solenoid coils. It provides valuable information about the condition of the coils and helps ensure proper functioning.

By taking the time to check the multimeter reading, you can identify any potential problems early on and take appropriate action to resolve them.

Step 7: Analyzing the Results

Testing an ATV winch solenoid with a multimeter is a straightforward process that can help diagnose any issues with the solenoid. Start by setting your multimeter to the continuity test or ohms setting. Then, disconnect the power supply to the winch and locate the solenoid.

Using the multimeter’s probes, touch one probe to the positive terminal and the other probe to the negative terminal of the solenoid. If the multimeter reads a resistance value within the specified range, it indicates that the solenoid is functioning correctly. However, if the multimeter reads an infinite resistance or no resistance at all, it suggests a problem with the solenoid, such as a broken coil or shorted circuit.

In such cases, it is recommended to replace the solenoid to ensure the proper functioning of the ATV winch. Remember to always consult the manufacturer’s instructions for specific testing procedures.

Step 7.1: Normal Readings

In the process of analyzing the results of a blood test, it is important to understand what constitutes normal readings. Normal readings refer to the range of values that are considered within the typical or expected range for a specific test. These ranges are determined by taking into account various factors such as age, gender, and overall health.

For example, a normal blood pressure reading for an adult is typically around 120/80 mmHg. If the readings fall within this range, it indicates that the individual’s blood pressure is within the normal range. However, it is important to note that normal readings may vary depending on the specific test being conducted.

It is always advisable to consult with a healthcare professional or refer to the reference range provided by the laboratory conducting the test for a more accurate interpretation of the results.

Step 7.2: Abnormal Readings

abnormal readings, analyzing the results, data analysis, diagnostic tests, outlier values, patterns, statistical significance, medical tests. In the process of analyzing the results of diagnostic tests, it is important to keep an eye out for abnormal readings or outlier values. These abnormal readings can provide valuable insights into a patient’s condition or the effectiveness of a treatment.

When analyzing data, we are often looking for patterns or statistical significance, and abnormal readings can be a clue that something is amiss. These abnormal readings could be due to a variety of factors, such as errors in measurement or the presence of an underlying condition. It is important to carefully evaluate these abnormal readings to determine if they are significant or if they may need to be retested.

By paying attention to abnormal readings, we can ensure that our data analysis is thorough and accurate, leading to better medical outcomes for patients.

Are you ready to wrap up your blog post with a strong and impactful conclusion? The conclusion is your final chance to leave a lasting impression on your readers and leave them with a sense of closure and satisfaction. It’s like the grand finale of a fireworks show, where all the dazzling lights and explosive sounds come together to create a memorable experience. Just like how a fireworks display builds up in intensity and complexity, your conclusion should build upon the ideas and arguments you have presented in your blog post.

It should tie all the loose ends together and provide a sense of resolution. Think of your conclusion as the final brushstroke on a masterpiece painting. It’s the finishing touch that completes the picture and gives it a sense of unity.

Without a strong conclusion, your blog post may feel incomplete or lacking in direction. But what makes a conclusion truly effective? A good conclusion should summarize the main points of your blog post in a concise and engaging manner. It should also leave room for further thought or discussion, perhaps by posing a rhetorical question or offering a call to action.

In a way, your conclusion is like the cherry on top of a delicious ice cream sundae. It adds that extra something special and makes the entire experience more satisfying. So as you reach the end of your blog post, take a moment to consider how you can craft a conclusion that will leave your readers feeling satisfied and inspired.

By doing so, you can ensure that your blog post has a lasting impact and leaves a memorable impression.

Summary of Testing Process

When it comes to testing an ATV winch solenoid with a multimeter, it’s important to follow a step-by-step process for accurate results. The first step is to disconnect the power supply to the winch solenoid to ensure safety during the testing process. Next, use the multimeter to check the resistance of the solenoid.

Set the multimeter to the resistance (ohms) setting and touch the probes to the terminals of the solenoid. A reading of zero or a very low resistance indicates a short circuit, and a high resistance reading may indicate an open circuit. Additionally, the multimeter can be used to test the solenoid coil’s continuity by setting the meter to the continuity or beep mode and touching the probes to the coil terminals.

If there is no beep or continuity, it could mean that the coil is faulty. By following these steps and using a multimeter, you can effectively test an ATV winch solenoid to ensure its functionality.

Next Steps

If you own an ATV with a winch, you know how important it is to keep it in good working order. One component that can sometimes cause issues is the winch solenoid. The solenoid is responsible for controlling the power supply to the winch motor.

If you suspect that your ATV winch solenoid is faulty, you can easily test it using a multimeter. A multimeter is a handy tool that can measure voltage, resistance, and continuity. To test the solenoid, start by setting your multimeter to the resistance (ohms) setting.

Then, disconnect the wires from the solenoid to isolate it from the rest of the winch system. Connect the multimeter leads to the two terminals on the solenoid and take a reading. A reading of zero or a very low resistance means that the solenoid is shorted and needs to be replaced.

On the other hand, a reading of infinity or a very high resistance indicates an open circuit and also requires replacement. By testing the ATV winch solenoid with a multimeter, you can quickly diagnose any issues and take the necessary steps to repair or replace it.

Conclusion

In conclusion, testing an ATV winch solenoid with a multimeter requires the perfect blend of technical savvy and adventurous spirit. Just like riding an ATV off-road, it’s all about finding the right balance. Using a multimeter is like embarking on an exciting treasure hunt, with each measurement leading you closer to the solution.

As you navigate the treacherous terrain of electrical currents and resistance levels, the multimeter becomes your trusty compass, guiding you towards the truth. But beware! Just as a wild ride on an ATV can leave you with a sore backside, testing a winch solenoid can be a bumpy ride. It requires steady hands and a keen eye for detail.

You must approach the task with caution, fully aware of the potential shocks and surges that may come your way. With the multimeter in your hand, you become a detective, searching for clues that will unravel the mystery of the winch solenoid. Each measurement you take is a piece of evidence, bringing you closer to the truth behind its functionality.

So, grab your multimeter and prepare to embark on a thrilling journey. As you test the ATV winch solenoid, let your wit and cleverness shine, turning this technical task into a grand adventure. And when you finally conquer the challenge, bask in the satisfaction of a job well done, knowing that you have tamed the wild beast that is the winch solenoid.

FAQs

What is an ATV winch solenoid?

An ATV winch solenoid is a device that controls the electrical flow to the winch motor, allowing it to be turned on and off.

Why is it necessary to test an ATV winch solenoid with a multimeter?

Testing an ATV winch solenoid with a multimeter can help diagnose any issues with the electrical flow, ensuring that it is functioning properly.

How can I test an ATV winch solenoid with a multimeter?

To test an ATV winch solenoid with a multimeter, you can measure the voltage at specific terminals and check for continuity.

What should the voltage reading be when testing an ATV winch solenoid?

The voltage reading when testing an ATV winch solenoid should match the manufacturer’s specifications, usually around 12V.

How can I check for continuity in an ATV winch solenoid using a multimeter?

To check for continuity in an ATV winch solenoid, set the multimeter to the continuity or resistance mode and touch the test leads to the appropriate terminals.

What are the common signs of a faulty ATV winch solenoid?

Common signs of a faulty ATV winch solenoid may include the winch not turning on, intermittent power to the winch motor, or a burning smell coming from the solenoid.

Can a faulty ATV winch solenoid be repaired or does it need to be replaced?

In most cases, a faulty ATV winch solenoid will need to be replaced rather than repaired, as repairing it may not provide a long-term solution.

Are there any safety precautions to take when testing an ATV winch solenoid with a multimeter? A8. It is important to disconnect the winch from the power source before testing the solenoid and to follow all safety guidelines provided by the manufacturer.

Can a faulty ATV winch solenoid cause damage to the winch motor?

Yes, a faulty ATV winch solenoid can cause damage to the winch motor if it fails to regulate the electrical flow properly.

Can I use any multimeter to test an ATV winch solenoid?

Yes, as long as the multimeter has the necessary functions for measuring voltage and continuity, it can be used to test an ATV winch solenoid.

Where can I find a replacement ATV winch solenoid if mine is faulty?

Replacement ATV winch solenoids can be found at ATV accessory stores, online retailers, or through the manufacturer of your ATV winch.

Are there any specific troubleshooting steps I should follow if my ATV winch solenoid is not working properly?

Yes, it is recommended to consult the user manual or contact the manufacturer for specific troubleshooting steps if you are experiencing issues with your ATV winch solenoid.