Greasing your wheel bearings may not be the most exciting task, but it’s an essential and often overlooked part of vehicle maintenance. By ensuring your wheel bearings are adequately lubricated, you can extend the life of your bearings, prevent wear and tear on your tires, and reduce the risk of breakdowns. However, manually greasing each bearing can be a messy, time-consuming task.

That’s where a wheel bearing grease packer comes in. In this blog, we’ll discuss how to use a wheel bearing grease packer to simplify the greasing process and keep your bearings in good condition.

Table of Contents

What is a Wheel Bearing Grease Packer?

If you’re wondering how to use a wheel bearing grease packer, then you’re in luck! A wheel bearing grease packer is a handy tool that helps you easily lubricate wheel bearings and keep them in good condition. To use it, simply fill the chamber with the grease of your choice, place the bearing inside, and then press down on the plunger to force the grease into the bearing. This ensures that the bearing is fully lubricated and helps prevent wear and tear over time.

Plus, using a wheel bearing grease packer can save you time and effort compared to manually greasing each bearing. So the next time you need to lubricate your wheel bearings, consider using a wheel bearing grease packer for a quick and easy solution.

Definition and Benefits

A wheel bearing grease packer is a handy tool that aids in the lubrication process of wheel bearings. Simply put, it’s a small device that helps pack grease into the bearing, reducing friction and heat buildup. This may seem like a small task, but it has enormous benefits for the overall function and longevity of your vehicle’s wheel bearings.

A well-lubricated bearing is less prone to wear and tear and lasts longer, which can save you money in repairs in the long run. Not to mention, proper lubrication also minimizes the risk of accidents caused by wheel bearing failure, increasing safety on the road. If you’re looking to invest in a wheel bearing grease packer, you’ll be glad to know that they are affordable, easy to use, and can help keep your vehicle running smoothly for years to come.

Steps to Use a Wheel Bearing Grease Packer

If you’re looking to maintain your vehicle’s wheel bearings, it’s important to know how to use a wheel bearing grease packer. The process is fairly simple and straightforward. First, you’ll need to remove the old grease and clean the bearings.

Then, fill the grease packer with fresh grease and place the bearings inside. Pump the plunger to push the grease into the bearings until they are completely filled. It is essential to ensure that the grease is evenly distributed and that the bearings are not overfilled.

Overfilling can lead to overheating and premature failure of the bearing. By using a wheel bearing grease packer, you can quickly and easily maintain your vehicle’s wheel bearings, ensuring smooth and safe driving.

Step 1: Gather Required Materials

If you need to repack your wheel bearings, using a wheel bearing grease packer can save you time and make the process much easier. The first step is to gather the required materials. You will need a wheel bearing grease packer, which can be purchased at most auto parts stores or online.

You will also need a high-quality wheel bearing grease, gloves to protect your hands, and a clean work space. It’s important to choose a grease that is specifically designed for wheel bearings, as it will provide the necessary lubrication and protection. Once you have all your materials gathered, you can begin the process of repacking your bearings.

With a little patience and attention to detail, you can ensure that your wheel bearings are well lubricated and ready to go.

Step 2: Mount the Wheel Bearing Grease Packer

One of the essential steps in using a wheel bearing grease packer is to mount it correctly. This may seem like a basic step, but it is crucial to ensure that the grease is distributed evenly throughout the bearing. To begin, locate the grease packer’s mounting pins and align them with the holes on the bearing packer.

Once the pins and holes match, gently push the two parts together until they snap into place. Ensure that the packer is secured tightly to prevent any grease leaks. When mounting the grease packer, it is essential to follow the manufacturer’s instructions thoroughly.

This will ensure that you are using the tool correctly and that your bearings are adequately lubricated. Remember, the ultimate goal of using a packer is to distribute grease evenly, so it is essential to take every step very carefully.

Step 3: Fill the Grease Packer with Grease

To use a wheel bearing grease packer, the next step after adding grease is to fill the packer with more grease. This is done by placing the lid on top of the packer and pumping the lever a few times until enough grease is present in the chamber. It’s important not to overfill the packer, as this can lead to unnecessary mess and wasted grease.

As you pump the lever, keep an eye on the color of the grease flowing out of the bottom of the packer. Ideally, the grease should be the same color as the fresh grease you added earlier. Once the packer is full, it’s ready to be used to apply grease to your wheel bearings.

By using a grease packer, you can ensure that your wheel bearings are lubricated evenly and effectively, extending their lifespan and keeping your vehicle running smoothly.

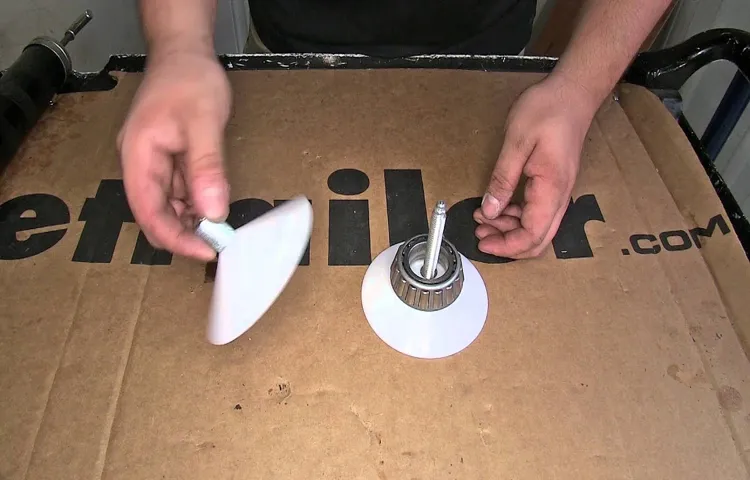

Step 4: Insert the Bearing into the Packer

When it comes to maintaining your vehicle, it’s crucial to take care of its parts, including the wheel bearings. Using a wheel bearing grease packer is a great way to ensure that your bearings stay lubricated properly. To begin, choose the correct-sized packer and fill it with the lubricant of your choice.

Next, place the bearing on top of the packer and press down firmly until it is seated correctly. Once the bearing is in place, gently apply pressure until the lubricant begins to flow through the bearing and out the other side. Finally, insert the bearing into the packer and continue applying pressure until the bearing is fully seated.

By following these simple steps, you’ll help extend the life of your wheel bearings and avoid costly repairs down the road. So why not try using a wheel bearing grease packer for your next maintenance task and see the difference it can make?

Step 5: Apply Pressure to Pack the Grease

Applying pressure to pack the grease is a crucial step when using a wheel bearing grease packer. This step ensures that the grease is thoroughly distributed throughout the wheel bearing, protecting it from high temperatures and corrosion. Once the wheel bearing is in position, insert the nozzle of the grease packer into the center of the bearing and apply moderate pressure to pack the grease.

It’s essential to monitor the amount of pressure you’re applying to avoid over-packing, as this can harm the bearing’s longevity. A reputable wheel bearing grease packer will feature a pressure release valve that you can release to prevent over-packing. By doing this, you’ll ensure that the bearing is appropriately lubricated and extends its lifespan.

Step 6: Rotate the Bearing

When it comes to using a wheel bearing grease packer, there are a few essential steps to follow. Once you’ve filled the packer with grease, the next step is to rotate the bearing. Simply place the bearing onto the small peg on the packer and use the handle to turn the bearing.

This will allow the grease to penetrate all areas of the bearing, ensuring that it’s thoroughly lubricated. While rotating the bearing, you should pay special attention to any areas that are rusted or corroded, as these areas may need extra lubrication. It’s also a good idea to rotate the bearing a few times in both directions to ensure maximum coverage.

Once you’ve finished rotating the bearing, you can use a cloth to remove any excess grease and move on to the next bearing. By following these simple steps, you can ensure that your bearings are properly lubricated, which will help extend their lifespan and improve the performance of your vehicle.

Tips for Using a Wheel Bearing Grease Packer

If you’re changing your car’s wheel bearings by yourself and want to make the process easy and efficient, using a wheel bearing grease packer is a great idea. This tool can pack fresh grease into the bearings and force out the old grease, making the bearings function effectively for an extended period. However, there are some tips you should keep in mind when using a wheel bearing grease packer.

Firstly, it’s essential to clean the bearings thoroughly before putting them in the packer. Remove any old grease with a solvent, but avoid using water, which can cause rusting. Secondly, apply enough pressure to fill the bearings with fresh grease, but avoid over-packing them.

Too much grease can cause the bearings to overheat, which can damage your car’s wheels and cause a potential accident. Lastly, avoid mixing incompatible grease types and consult your vehicle’s manual for guidance on the right type of grease to use. By following these tips, you’ll have an easy time using the wheel bearing grease packer and ensure prolonged use of your car’s wheel bearings.

Tip 1: Choose the Right Grease

When it comes to using a wheel bearing grease packer, one of the most critical factors to consider is choosing the right type of grease. Not all greases are created equal, and using the wrong one could lead to significant issues down the road. To ensure optimal performance and longevity of your bearings, you should choose a high-quality grease that’s specifically designed for wheel bearings.

Look for one that offers excellent protection against high temperatures, corrosion, and water damage, as these are common issues that can compromise the effectiveness of your bearings over time. Additionally, consider the type of driving you’ll be doing and the climate in which you’ll be operating your vehicle, as this can also affect the performance of the grease. Ultimately, taking the time to choose the right grease is a small investment that can pay off in the long run, as it can help to prevent costly repairs and maintenance down the road.

By prioritizing the quality of your grease, you can ensure that your wheels and bearings function optimally for years to come.

Tip 2: Use the Right Amount of Grease

Wheel bearing grease packer When it comes to using a wheel bearing grease packer, it’s important to know how much grease to use. Over-greasing can cause a buildup of pressure, leading to seal damage and leakage. On the other hand, under-greasing can cause increased friction, leading to accelerated wear and tear on the bearings.

The key is to use the right amount of grease recommended by the manufacturer. This can be measured by using a scale or by filling the packer until the grease begins to come out of the top. It’s also important to use high-quality grease specifically designed for wheel bearings, as it contains additives to resist water, corrosion, and extreme temperatures.

By using the correct amount of grease, you can ensure smooth, safe, and long-lasting operation of your vehicle. So always keep the right amount of wheel bearing grease packer and get going!

Tip 3: Keep the Grease Packer Clean

One crucial tip for using a wheel bearing grease packer is to keep the device clean. As you use the packer, grease can accumulate on the surfaces and make it harder for the tool to function correctly. This can cause issues with the pressure and distribution of the grease, leading to uneven lubrication of the bearings.

To prevent these problems, it’s essential to wipe down the packer after every use. Use a clean cloth or rag to remove any excess grease from the surfaces, including the plungers and fittings. You can also use a small brush or toothbrush to scrub away any stubborn bits of grease.

By keeping your packer clean, you’ll ensure that it works efficiently and accurately every time you use it. So, remember to add this simple but crucial step to your maintenance routine to keep your wheels rolling smoothly and prevent any potentially costly repairs in the future.

Conclusion

In conclusion, using a wheel bearing grease packer is like giving your car’s bearings a spa day. Just like how a masseuse works the knots out of your neck and shoulders, the grease packer thoroughly coats and distributes grease throughout the bearing, ensuring smooth and efficient operation. So go ahead and treat your car’s bearings to a spa day with a wheel bearing grease packer, they deserve it!”

FAQs

What is a wheel bearing grease packer?

A wheel bearing grease packer is a tool used to apply grease to the wheel bearings of a vehicle.

How do I use a wheel bearing grease packer?

To use a wheel bearing grease packer, fill it with grease and then place the wheel bearing onto the tool. Pump the grease through the bearing until it is fully packed.

What type of grease should I use with a wheel bearing grease packer?

Always use a high-quality wheel bearing grease that is recommended by the manufacturer of the vehicle or the grease packer tool.

Can I pack wheel bearings without a grease packer?

Yes, it is possible to pack wheel bearings without a grease packer, but using a tool will ensure that the grease is evenly distributed throughout the bearing.

How often should I grease my wheel bearings?

The frequency of greasing your wheel bearings depends on the manufacturer’s recommendations for your particular vehicle, but typically it should be done at least once a year or every 20,000 miles.

Why is it important to grease my wheel bearings?

Wheel bearings that are not properly greased can cause excessive wear and tear, leading to costly repairs down the line. Properly greased bearings also reduce friction and increase fuel efficiency.

Can I reuse the grease that is leftover in my grease packer?

It is not recommended to reuse leftover grease as it may contain contaminants that can cause damage to your vehicle’s bearings. It is best to use fresh grease each time.