If you’ve ever installed running boards on your vehicle, you know that it’s not just a matter of screwing them in and calling it a day. There’s a lot more to it, and one crucial aspect that often gets overlooked is the torque specs for the bolts. But why are torque specs so important for running board bolts? Well, imagine if you didn’t tighten them enough – the running boards could end up coming loose while you’re driving, posing a safety risk.

On the other hand, if you overtighten the bolts, you could damage the running boards or even the vehicle itself. Finding the right balance is essential, and that’s where torque specs come in. In this blog post, we’ll explore the importance of torque specs for running board bolts and why you shouldn’t overlook this crucial step in the installation process.

So let’s dive in and discover why torque matters!

Table of Contents

What are torque specs?

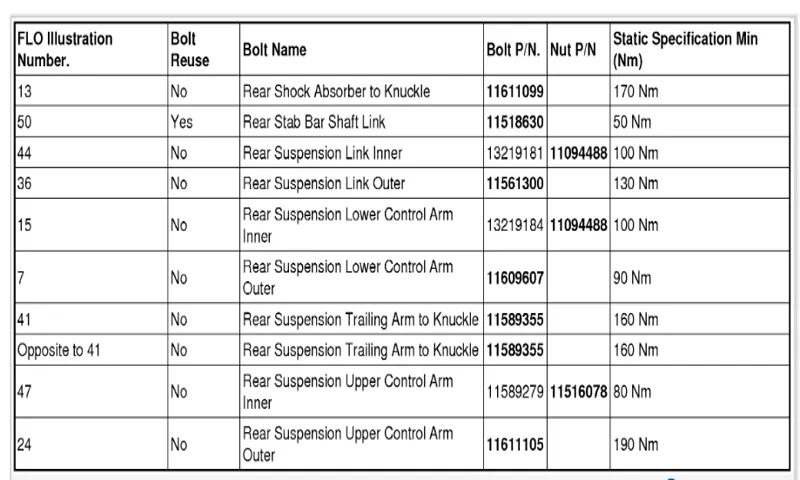

Yes, there is a torque spec for running board bolts. Torque specs are the recommended tightness or tension that should be applied to a bolt or nut in order to ensure proper installation. In the case of running board bolts, it is important to follow the manufacturer’s torque specifications to ensure that the bolts are correctly tightened and secure.

This is especially crucial for running boards, as they are designed to support the weight of individuals entering and exiting the vehicle. Applying the correct torque to the running board bolts helps to prevent them from loosening or becoming unstable over time. It is always a good idea to consult the owner’s manual or contact the manufacturer for the specific torque spec for your particular running board bolts.

Following these specifications will help to ensure the safety and longevity of your running boards.

Definition of torque specs

“What are torque specs?”

Why torque specs are important for running board bolts

running board bolts

How to Determine Torque Specs for Running Board Bolts

When it comes to installing running boards on your vehicle, it’s important to ensure that the bolts are properly tightened to avoid any issues down the road. While there may not be a specific torque specification for running board bolts, there are some general guidelines you can follow. It’s recommended to use a torque wrench and tighten the bolts to the manufacturer’s specifications for the specific vehicle model.

If those specifications are not provided, a good rule of thumb is to tighten the bolts snugly, but not too tight. You want to make sure they are secure, but not over-tightened, as this could potentially damage the running board or the vehicle itself. It’s always a good idea to consult the installation instructions provided by the running board manufacturer for any additional guidance or specifications.

Remember, it’s better to err on the side of caution and check the tightness of the bolts periodically to ensure they remain securely fastened.

Recommendations from the manufacturer

running board bolts, torque specs, manufacturer, recommendations, determine torque specs

Using a torque wrench

torque specs, running board bolts, torque wrench If you’re installing running boards on your vehicle, it’s important to make sure they’re securely attached. One of the key factors in achieving a secure installation is using the proper torque specs for the running board bolts. Torque specs refer to the amount of force that should be applied when tightening a bolt.

Using a torque wrench is the best way to ensure that you’re applying the correct amount of torque. To determine the torque specs for your running board bolts, you’ll first need to consult the installation instructions provided by the manufacturer. In these instructions, you should find the specific torque values recommended for the bolts.

These torque values are typically given in foot-pounds or Newton-meters. Once you have the torque values, you can use a torque wrench to tighten the bolts to the specified torque. A torque wrench is a tool that measures the amount of torque being applied to a bolt.

It allows you to tighten the bolt to the exact torque specified, ensuring that it is neither too loose nor too tight. To use a torque wrench, you’ll first need to set it to the correct torque value. Most torque wrenches have a scale or dial that allows you to adjust the torque.

Simply turn the wrench until the desired torque value aligns with the indicator on the handle. When tightening the running board bolts, it’s important to use a criss-cross or star pattern. This means starting at one corner and alternating diagonally to the opposite corner.

By doing this, you distribute the force evenly and ensure that the running board is properly attached. Remember, using a torque wrench is crucial for achieving the proper torque specs for your running board bolts. This will help prevent the bolts from becoming loose over time and ensure a secure installation.

Consulting a professional

“running board bolts, torque specs, consulting a professional” When it comes to installing or replacing running boards on your vehicle, it’s important to ensure that the bolts are tightened to the correct torque specs. Torque specs refer to the amount of force needed to tighten the bolts to the proper level. This is crucial because if the bolts are not tightened enough, they may come loose while driving, posing a safety hazard.

On the other hand, if the bolts are tightened too much, they could damage the running boards or the vehicle itself. Determining the correct torque specs for running board bolts can be a bit tricky, as it varies depending on the specific vehicle and running board design. As such, it is highly recommended to consult a professional, such as a mechanic or an automotive specialist, who can provide you with the precise torque specs for your particular vehicle model.

They have the expertise and knowledge to ensure that the running boards are securely attached without risking any damage or safety concerns. Consulting a professional not only gives you peace of mind but also helps to protect your investment and the safety of yourself and your passengers.

Online resources for torque specs

torque specs, running board bolts, online resources, determine Running boards can be a practical and stylish addition to any vehicle, providing a convenient step for passengers to easily enter and exit the vehicle. However, it’s important to ensure that the running boards are securely installed using the correct torque specs for the bolts. Determining the torque specs for running board bolts can be a bit confusing, but thankfully, there are online resources available to help.

These resources provide valuable information on the recommended torque specifications for various makes and models of vehicles. By using these online resources, you can ensure that your running boards are properly installed and securely attached to your vehicle. So, before you start installing your running boards, take the time to research the appropriate torque specs.

With the help of online resources, you can confidently tackle this project and enjoy the benefits of stylish and functional running boards on your vehicle.

Common Torque Specs for Running Board Bolts

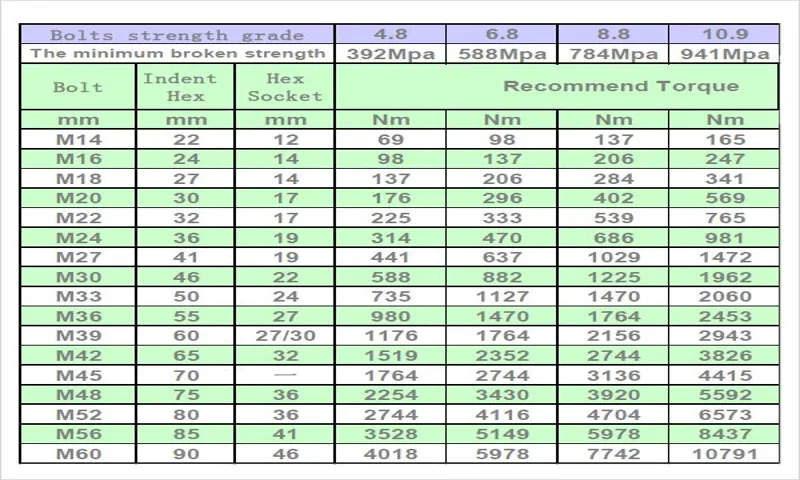

Wondering if there is a specific torque specification for running board bolts? Well, the answer is yes! When it comes to installing or tightening the bolts on your running boards, it is important to follow the recommended torque specifications to ensure proper installation and to prevent any damage or accidents. While the specific torque specs may vary depending on the make and model of your vehicle, a general guideline is to use a torque wrench to tighten the bolts to around 18 to 25 foot-pounds. However, always refer to the owner’s manual or contact the manufacturer for the exact torque specs for your specific running board bolts.

By following these torque specifications, you can ensure that your running boards are securely attached and ready to provide the added convenience and style to your vehicle.

General torque range for running board bolts

running board bolts, torque range for running board bolts When it comes to installing running boards on your vehicle, it’s important to make sure the bolts are tightened properly. The torque, or rotational force, applied to the bolts can greatly impact their effectiveness and durability. While the specific torque range can vary depending on the make and model of your vehicle, there is a general range that can be followed.

Typically, the torque range for running board bolts falls between 20-30 ft-lbs. This range ensures that the bolts are securely fastened without being over-tightened, which can lead to damage or failure. It’s always a good idea to consult your vehicle’s owner manual or the instructions provided with your running board kit for the specific torque specifications.

Additionally, using a torque wrench can help ensure that you achieve the correct torque setting and avoid any potential issues down the road. So, the next time you install running boards on your vehicle, remember to tighten those bolts within the recommended torque range for a safe and secure installation.

Specific torque specs for popular running board brands/models

running board bolts, torque specs, specific torque specs, popular running board brands, models Are you looking to install running boards on your vehicle? One crucial step in this process is tightening the bolts to the correct torque specification. However, different running board brands and models may have different torque specifications. That’s why it’s important to know the specific torque specs for your running boards to ensure a secure and stable installation.

While there are many popular running board brands and models out there, here are some common torque specs that you might find useful. Remember to always refer to the manufacturer’s instructions for your specific running board brand and model to ensure the proper torque is applied. Happy installing!

Tips for Properly Applying Torque to Running Board Bolts

“Is there a torque spec for running board bolts?” This is a common question that arises when installing running boards on a vehicle. While there may not be a specific torque specification provided by the manufacturer, it is important to properly apply torque to ensure the running boards are securely attached. Torque refers to the amount of rotational force applied to a bolt or fastener.

When it comes to running board bolts, it is necessary to apply enough torque to prevent the bolts from becoming loose, while also avoiding over-tightening and potentially damaging the vehicle’s body or the bolts themselves. One recommended approach is to start by hand-tightening the bolts and then using a torque wrench to gradually apply torque in a clockwise direction until the desired tightness is achieved. This allows for a firm and secure attachment without risking damage.

It is also important to periodically check the tightness of running board bolts, especially after driving on rough terrain or over time as vibrations and other factors may cause them to become loose. Taking the time to properly apply torque to running board bolts can help ensure a safe and secure installation that will withstand the test of time.

Using the correct torque wrench

Using the correct torque wrench is crucial when it comes to properly applying torque to running board bolts. With the right torque wrench, you can ensure that the bolts are tightened to the appropriate specifications, preventing any issues with loose or over-tightened bolts. There are a few tips to keep in mind when using a torque wrench for running board bolts.

First, make sure to select the correct torque setting on the wrench based on the manufacturer’s specifications. This will vary depending on the type of running board and the material it is made from. Second, always use the proper socket size and ensure that it is securely attached to the torque wrench.

This will help prevent slippage and ensure an accurate torque measurement. Finally, when applying torque to the bolts, use a smooth and steady motion. Avoid jerking or applying excessive force, as this can lead to inaccurate torque readings and potential damage to the running board or vehicle.

By following these tips and using the correct torque wrench, you can ensure that your running board bolts are properly tightened for a secure and safe installation.

Applying torque in a consistent and controlled manner

Torque is a crucial aspect of properly fastening running board bolts, but applying it correctly can be a challenge. To ensure consistent and controlled torque application, there are a few tips you should keep in mind. First and foremost, it’s important to use a torque wrench that is appropriate for the job.

This tool will allow you to accurately measure the amount of torque being applied to the bolts, ensuring they are tightened to the correct specifications. Secondly, it’s crucial to apply torque in a smooth and steady manner. Jerky or sudden movements can lead to inaccurate torque application, potentially resulting in loose or overtightened bolts.

Additionally, consider using a lubricant on the threads of the bolts to reduce friction, allowing for more accurate torque readings. Lastly, always double-check the torque specifications provided by the manufacturer for the running board bolts you are working with. Each bolt may have different torque requirements, so it’s important to follow these guidelines to prevent damage to the bolts or the running board itself.

By following these tips, you can ensure that torque is applied properly and consistently to your running board bolts, providing a secure and reliable attachment.

Double-checking torque after installation

running board bolts, torque, installation, double-checking, tips When it comes to installing running boards on your vehicle, properly applying torque to the bolts is crucial for ensuring a secure and stable fit. Torque refers to the amount of force used to tighten the bolts, and it is essential to follow the manufacturer’s specifications to prevent over-tightening or under-tightening. Double-checking the torque after installation is also important to confirm that the bolts are securely fastened.

Here are some tips for properly applying torque to running board bolts: Use a torque wrench: To accurately apply the correct amount of torque, it is recommended to use a torque wrench. This tool allows you to set a specific torque value and ensures consistent tightening across all bolts.

Follow the manufacturer’s instructions: Each running board may have different torque requirements, so it is important to refer to the manufacturer’s instructions. These instructions will provide the recommended torque value and any specific tightening sequence.

Tighten bolts in a cross pattern: When tightening the bolts, it is best to follow a cross pattern rather than tightening them all in a clockwise or counterclockwise direction. This helps distribute the torque evenly and prevents warping or damage to the running board.

Double-check the torque: Once all the bolts have been tightened, it is a good idea to double-check the torque. This can be done by going back over each bolt and ensuring that the torque wrench clicks or indicates the specified torque value.

By following these tips, you can ensure that the running board bolts are properly tightened and that your running boards are securely attached to your vehicle. Taking the time to double-check the torque after installation will give you peace of mind knowing that your running boards are safe and stable.

Final Thoughts on Torque Specs for Running Board Bolts

So, you’ve just purchased some new running boards for your vehicle, and now you’re wondering if there is a torque spec for the bolts that hold them in place. Well, the answer is yes, there is a torque spec for running board bolts. It’s important to follow this spec to ensure that the bolts are tightened to the correct level and that the running boards are securely attached to your vehicle.

The torque spec for running board bolts can vary depending on the specific make and model of your vehicle, as well as the type of running boards you have. It’s always best to refer to the manufacturer’s instructions or consult a professional for the exact torque spec for your particular setup. However, as a general guideline, most running board bolts should be tightened to a torque of around 20-25 foot-pounds.

This is typically the range that provides a secure attachment without risking damage to the bolts or the vehicle. It’s also important to note that when tightening running board bolts, you should do so in a crisscross pattern. This helps to evenly distribute the torque and ensure a secure fit.

Start by tightening the bolts on one side of the running board, then move to the opposite side and repeat the process. This will help to prevent any warping or unevenness in the running board. Overall, following the correct torque spec for running board bolts is essential to ensure that your running boards are safely and securely attached to your vehicle.

By taking the time to properly tighten the bolts, you can enjoy the benefits of your running boards without worrying about them coming loose or causing damage.

Conclusion

In the quest for knowledge and the pursuit of perfection, one must grapple with life’s most pressing questions. And in the realm of automotive maintenance, few queries are as profound as the enigma of torque specifications for running board bolts. Now, dear reader, you may be thinking, “Why on earth would I need to know the torque spec for running board bolts?” Ah, but let me enlighten you.

You see, the world of running boards is a treacherous one, filled with uncertainties and dilemmas that only the boldest of souls dare to face. Imagine you’re cruising down the road, wind blowing through your hair, feeling like a modern-day cowboy. But suddenly, disaster strikes! Your running board starts to wobble, threatening to break free from its shackles and send you tumbling into the abyss of embarrassment.

In times like these, my friend, the importance of a torque spec becomes abundantly clear. It is the divine measurement that ensures the perfect balance between tightness and flexibility, preventing those dreaded running board mishaps. It keeps your steps secure, your confidence intact, and your cool-factor off the charts.

But alas, the gurus of automotive engineering have not deemed it necessary to bestow upon us a specific torque specification for running board bolts. So what are we mere mortals to do in the face of such uncertainty? Fear not, for I shall reveal the secret to navigating these uncharted waters. You see, determining the optimal torque for your running board bolts is a delicate dance between intuition and experience.

It is a matter of finding that magical sweet spot where the bolts find their perfect balance, snugly holding everything in place, while still allowing a slight give for when life throws you a curveball. So, my learned friend, the next time you embark on the task of installing or tightening your running board bolts, trust in your instincts. Go forth with a six-pack of wit, a dash of wisdom, and a healthy dose of trial and error.

And remember, in the realm of torque specs for running board bolts, there may not be concrete numbers, but there will always be adventure and a chance to leave your mark on the world of automotive brilliance.

FAQs

What is the torque spec for running board bolts?

The torque spec for running board bolts may vary depending on the specific make and model of your vehicle. It is recommended to consult your vehicle’s manufacturer or refer to the owner’s manual for the accurate torque specification.

Should I use a torque wrench to tighten running board bolts?

Yes, it is highly recommended to use a torque wrench when tightening running board bolts. This ensures that the bolts are tightened to the manufacturer’s specified torque, preventing over or under-tightening and ensuring proper installation.

Can I reuse running board bolts when reinstalling them?

It is generally not recommended to reuse running board bolts when reinstalling them. Over time, the bolts may experience wear or become damaged, leading to potential issues with stability and safety. It is best to replace the bolts with new ones to ensure optimal performance.

What can happen if running board bolts are not tightened properly?

If running board bolts are not tightened properly, they may come loose while driving, leading to instability and potential safety hazards. Loose bolts can cause the running boards to rattle or even detach from the vehicle, posing a risk to both the vehicle occupants and other road users.

Can I install running boards without using any bolts?

While some running boards may have alternative installation methods such as adhesive tapes, it is generally recommended to use bolts for secure and reliable attachment. Bolts provide a stronger and more durable connection, especially for heavy-duty or off-road applications.

How often should I check the tightness of my running board bolts?

It is a good practice to periodically check the tightness of running board bolts, especially after off-road driving or extreme weather conditions that may cause vibrations. Regular inspections can help identify any loose bolts and prevent potential safety issues.

Can I tighten running board bolts without any specific tools?

It is highly recommended to use appropriate tools such as a torque wrench or socket wrench when tightening running board bolts. Using proper tools ensures accurate torque application, reducing the risk of damage to the bolts or running board brackets.