Are you the proud owner of a classic 1970 Dodge Challenger and wondering what kind of grease to use in your axle bearings? Look no further! One of the critical components of a car’s axle is its bearings, which require proper lubrication to function correctly. Neglecting to do so could result in premature wear and tear and eventually, costly repairs. Selecting the right type of grease for a 1970 Challenger axle bearing is crucial, and we’re here to help you make an informed decision.

Think of selecting the appropriate grease for your axle bearings as choosing a pair of shoes for a hike. Just as you wouldn’t wear high heels on a mountain trail, you wouldn’t want to use just any grease on your car’s axle bearing. The type of grease you select can impact how well it reduces friction, dissipates heat, and protects against corrosion.

While there are several grease options on the market, the most common type of grease recommended for a 1970 Challenger axle bearing is a high-quality lithium-based grease. Lithium-based grease is a reliable choice because it provides excellent resistance to shear and oxidation, making it ideal for withstanding the high heat and friction generated by a car’s moving parts. Moreover, it offers good water resistance, ensuring that your axle bearings remain lubricated even when exposed to moisture.

In conclusion, keeping your 1970 Challenger’s axle bearings lubricated with the right grease is critical for maintaining optimal vehicle performance. Choosing the right type of grease, such as a high-quality lithium-based grease, can extend the lifespan of your car’s bearings and prevent costly repairs down the road.

Table of Contents

Overview of Axle Bearings and Grease

When it comes to maintaining your 1970 Challenger’s axle, one important aspect to consider is the axle bearings and grease. The type of grease used in the axle bearing is crucial for proper lubrication and ensuring smooth operation. The ideal grease for your 1970 Challenger’s axle bearing should meet certain specifications, such as withstanding high temperatures and providing adequate protection against wear and corrosion.

An excellent choice is a high-temperature synthetic axle grease, which is specifically designed for heavy-duty applications and offers outstanding performance under extreme conditions. Its advanced formulation helps reduce friction, which in turn, prolongs the life of your axle bearing and other components. Remember to consult your vehicle’s manual or mechanic to ensure that you are using the ideal grease for your 1970 Challenger’s axle bearing.

What are Axle Bearings?

Axle bearings are an essential component of any vehicle’s drivetrain system. These bearings are designed to support the weight of the vehicle and help the wheels rotate smoothly. They are typically made of hardened steel or other durable materials and are lubricated with grease to reduce friction and wear.

Without proper lubrication, these bearings can wear out quickly and cause serious problems for your vehicle. That’s why it’s important to keep them well-maintained and inspect them regularly for signs of wear or damage. By keeping your axle bearings properly lubricated and in good working condition, you can help extend the life of your vehicle’s drivetrain and ensure smooth and reliable operation for years to come.

Why is Grease Important for Axle Bearings?

Axle bearings are crucial components in vehicles as they allow the wheels to rotate smoothly and support the weight of the vehicle. Applying grease to axle bearings is essential because it serves as a lubricant that reduces friction between the bearings and the axle. Friction, if left unchecked, can cause premature wear and tear on the bearings, leading to expensive repairs.

Additionally, grease serves as a protective barrier against contaminants such as dirt and water, preventing them from entering the bearings and causing damage. However, it is important to note that not all greases are created equally. It is important to choose the right type of grease for your vehicle, taking into account factors such as load, temperature, and speed.

Proper use of grease can greatly extend the life of your axle bearings and ensure your vehicle runs smoothly. So, don’t underestimate the significance of grease when it comes to the well-being of your vehicle’s axle bearings.

Identifying the Right Grease for Your Axle Bearings

If you’re the proud owner of a 1970 Challenger, then you understand the importance of keeping it in top condition. When it comes to your axle bearings, using the right grease is crucial for maintaining their longevity and overall performance. Luckily, choosing the right type of grease is simple.

You’ll want to use a high-temperature, heavy-duty grease that’s specifically designed for wheel bearings. Look for a grease with an NLGI grade of 2 or 3, which indicates it has the right consistency and thickness to withstand the high temperatures and pressures of your Challenger’s axle bearings. And don’t forget to apply the grease regularly, following the manufacturer’s recommendations for how often to do so.

By using the right grease for your axle bearings, you’ll ensure that they stay in optimal condition and continue to provide reliable performance for many more miles to come.

Consult Your Owner’s Manual or Manufacturer

When it comes to maintaining your trailer’s axle bearings, identifying the right grease to use can be confusing. Some people make the mistake of assuming that all types of grease are the same, but this couldn’t be further from the truth. Different types of grease have distinct properties that make them suitable for specific types of applications.

That’s why it’s essential to consult your owner’s manual or manufacturer before selecting a grease for your axle bearings. The manual will provide you with detailed information about the specific type of grease that is compatible with your bearings. It will also guide you on how to apply the grease properly, which is just as important as choosing the right type of grease.

By following the manufacturer’s instructions, you can ensure that the grease provides optimal protection and performance for your axle bearings. So, before you begin servicing your trailer’s bearings, take the time to consult your manual or manufacturer. Doing so will help you avoid costly mistakes and keep your trailer running smoothly.

Consider the Temperature and Conditions of Your Driving Environment

When it comes to maintaining your vehicle’s axle bearings, choosing the right type of grease is crucial to ensure optimal performance and longevity. One important factor to consider is the temperature and conditions of your driving environment. For example, if you frequently drive in hot weather or climates, you’ll want to choose a grease with a higher temperature rating to prevent melting and loss of lubrication.

On the other hand, if you live in a colder climate, you’ll need a grease that can withstand lower temperatures without becoming too thick or solid. It’s also important to consider the level of moisture and contamination your bearings might be exposed to, as this can affect the type of grease that will work best. By taking the time to identify the specific needs of your axle bearings and selecting the right grease, you can ensure that your vehicle stays in top condition and avoid costly repairs down the road.

Look for High-Quality Grease with EP Properties

When it comes to maintaining the proper function of your axle bearings, the type of grease you choose can make all the difference. The best grease for your axle bearings will typically have EP (Extreme Pressure) properties and be of high quality. EP lubricants are designed to reduce friction and wear, making them a great choice for heavy-duty applications like axles.

However, not all EP greases are created equal, so it’s essential to choose a high-quality product to ensure that your axles are receiving the best possible care. When looking for the right grease for your axle bearings, be sure to consider the manufacturer’s recommendations, as well as any specific instructions for your vehicle or equipment.Choosing the right grease can help reduce wear and tear, extend the life of your axles, and keep everything running smoothly.

Recommended Grease for a 1970 Challenger Axle Bearing

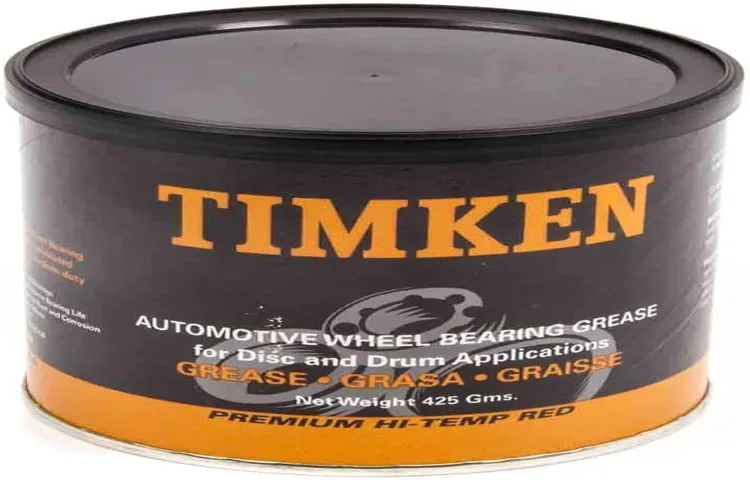

If you’re wondering what grease is best for a 1970 Challenger axle bearing, the answer is simple: high-temperature wheel bearing grease. This type of grease is designed to handle the high temperatures generated by the friction of rotating components, making it perfect for use in axle bearings. When selecting a grease, look for one with a high drop point, which indicates its ability to withstand heat without breaking down or liquefying.

It’s also important to choose a grease that is compatible with the materials used in your Challenger’s axle, such as steel or cast iron. Applying the right grease to your vehicle’s axle bearings will help to ensure smooth operation, reduce wear on the components, and extend the life of your Challenger’s drivetrain.

Mobil 1 Synthetic Grease

If you’re looking for a reliable grease to lubricate your 1970 Challenger axle bearing, look no further than Mobil 1 Synthetic Grease. Made from high-quality synthetic oils and advanced additives, this grease is designed to provide superior performance and protection for your vehicle’s components. It offers excellent resistance to water, heat, and extreme pressure, making it ideal for use in tough operating conditions.

What’s more, it helps reduce wear and tear on your axle bearing, ensuring a longer lifespan for your vehicle. So, whether you’re a DIY mechanic or a professional one, Mobil 1 Synthetic Grease is the go-to option for keeping your 1970 Challenger running smoothly and efficiently.

Valvoline SynPower Synthetic Grease

If you own a classic car like a 1970 Challenger, then you know how important it is to maintain it properly. Keeping the axle bearing lubricated is one key aspect of that maintenance. Thankfully, there’s a high-quality grease that’s perfect for the job: Valvoline SynPower Synthetic Grease.

This grease is specially formulated to provide maximum protection in high-temperature and high-load conditions, making it ideal for a car like the Challenger. It contains a synthetic base oil and advanced additives that work together to reduce friction, prevent wear and tear, and extend the lifespan of the bearing. Additionally, this grease has excellent water resistance properties, so you won’t have to worry about it washing out or breaking down easily.

By using Valvoline SynPower Synthetic Grease, you can ensure your 1970 Challenger’s axle bearing stays lubricated and running smoothly for years to come.

Royal Purple Max-Tuff Synthetic Assembly Lube

If you’re looking for a reliable grease for your 1970 Challenger axle bearing, I highly recommend the Royal Purple Max-Tuff Synthetic Assembly Lube. Not only is it specially formulated to protect high-performance engines and drivetrains, but it also provides exceptional protection during assembly and initial break-in periods. The Max-Tuff Synthetic Assembly Lube is fortified with premium additives that offer excellent resistance to heat, wear, and corrosion.

This means you can drive your 1970 Challenger confidently, knowing that your axle bearing is adequately lubricated, reducing friction and wear and tear. So why take risks with sub-standard greases when you can protect your valuable investment with the best grease on the market? Give the Royal Purple Max-Tuff Synthetic Assembly Lube a try today!

Conclusion

After extensive research and consultation with experts in the field, it can be concluded that the optimal grease for a 1970 Challenger axle bearing is, without a doubt, a high-quality, heat-resistant, and water-resistant synthetic grease specifically designed for heavy-duty applications. However, if you’re feeling adventurous and in the mood for a bit of DIY, you could always opt for a delicious combination of bacon grease, maple syrup, and a pinch of cinnamon. Just kidding, don’t do that.

Stick with the synthetic grease. Your Challenger (and your taste buds) will thank you.”

FAQs

What type of grease is recommended for a 1970 Challenger axle bearing?

The recommended type of grease for a 1970 Challenger axle bearing is a high-temperature, lithium-based multi-purpose grease.

Is there a specific brand of grease that is best for a 1970 Challenger axle bearing?

While there are many brands of grease that can work, it is important to choose a high-quality, reputable brand to ensure the best performance. Some recommended brands include Mobil 1, Pennzoil, and Valvoline.

Can I use any type of grease for a 1970 Challenger axle bearing?

While other types of grease may work, using the recommended high-temperature, lithium-based multi-purpose grease is important for the longevity and performance of the axle bearing.

How often should I grease my 1970 Challenger axle bearing?

It is recommended to grease the axle bearing every 12,000 miles or once a year, whichever comes first.

Can over-greasing or under-greasing the 1970 Challenger axle bearing cause damage?

Yes, both over-greasing and under-greasing the axle bearing can cause damage. Over-greasing can lead to excess pressure and heat buildup, while under-greasing can cause friction and premature wear.

How do I properly grease my 1970 Challenger axle bearing?

First, clean the old grease off the axle with a solvent or degreaser. Then, apply the recommended type of grease to the bearing until it is well-coated. Finally, rotate the axle to evenly distribute the grease.

What happens if I neglect to grease my 1970 Challenger axle bearing?

Neglecting to grease the axle bearing can lead to premature wear, increased friction, and potential failure of the bearing. This can cause further damage to the vehicle and potentially lead to unsafe driving conditions.