Everyone knows that when it comes to using electronic devices, things can get heated, quite literally. In order to prevent overheating, many devices, including inverters, employ a cooling system to maintain optimal performance. But have you ever wondered how this cooling system works? What exactly is inverter coolant, and what role does it play in keeping your devices running smoothly? In this blog post, we will dive into the world of inverter coolant, exploring its purpose, composition, and importance in maintaining the efficiency and longevity of your inverters.

So, let’s cool things down and get to the bottom of inverter coolant!

Table of Contents

What is Inverter Coolant?

Inverter coolant is a vital component in your car’s cooling system. It is specifically designed to regulate the temperature of the inverter, which is responsible for converting the DC current from the battery to AC current that powers the electric motor. Inverter coolant helps dissipate the heat generated by the inverter, preventing it from overheating.

Think of inverter coolant as a protective shield that keeps the inverter running smoothly and efficiently. Just like your body needs water to stay cool during a workout, your inverter needs coolant to stay cool during its operation. So, make sure to check your inverter coolant regularly and top it up if needed.

It’s a small but crucial part of your car’s overall performance!

Definition

inverter coolant

Purpose

inverter coolant, what is inverter coolant, cooling system inverter, benefits of inverter coolant

Composition

Inverter coolant is a vital component in the cooling system of an inverter or a power inverter. This coolant plays a crucial role in regulating the temperature of the inverter and ensuring its optimal performance. To understand why inverter coolant is important, let’s think of it like a car’s engine coolant.

Just like the engine coolant helps to keep the engine from overheating, the inverter coolant serves the same purpose for the inverter. It prevents the inverter from getting too hot and helps dissipate the excess heat generated during its operation. This is important because overheating can lead to damage to the inverter components and even cause a complete system failure.

By using a proper inverter coolant, you can ensure that your inverter operates efficiently and lasts longer. So, the next time you’re using an inverter, remember to check and maintain the coolant to keep your inverter running smoothly.

Benefits of Inverter Coolant

Inverter coolant, also known as refrigerant, is a vital component in inverter air conditioning systems. It plays a crucial role in the cooling process by absorbing heat from the indoor air and releasing it outside. Without inverter coolant, air conditioners would not be able to effectively cool a space.

But what makes inverter coolant so beneficial? Well, for starters, it has excellent thermal properties, meaning it can efficiently transfer heat. This allows the air conditioner to cool the room quickly and maintain a comfortable temperature. Inverter coolant also helps to prolong the lifespan of the air conditioning system by preventing overheating.

It circulates through the system, absorbing the excess heat generated during operation and carrying it away. This helps to prevent damage to the compressor and other components. Additionally, inverter coolant is environmentally friendly.

It does not contain any ozone-depleting substances, making it a much safer and greener option compared to older refrigerants. Overall, inverter coolant is a crucial element in air conditioning systems, ensuring efficient cooling, prolonging the lifespan of the system, and being environmentally friendly.

Efficient Heat Dissipation

inverter coolant, heat dissipation, benefits

Improved Performance

inverter coolant, improved performance, benefits

Extended Lifespan

inverter coolant, extended lifespan One of the key benefits of using inverter coolant in your cooling system is the extended lifespan it provides. Inverter coolants are designed to maintain a consistent and optimal temperature for your cooling system, which not only helps prevent overheating but also reduces wear and tear on the components. This means that your cooling system will be able to perform at its best for a longer period of time, leading to fewer breakdowns and costly repairs.

Imagine having a car that runs smoothly year after year, with minimal maintenance required. That’s the kind of longevity you can expect from using inverter coolant. It’s like giving your cooling system a rejuvenating boost, ensuring it stays in top-notch condition for years to come.

So, why settle for a cooling system that may break down sooner than later? Upgrade to inverter coolant and enjoy the benefits of an extended lifespan.

Types of Inverter Coolant

Inverter coolant is a type of liquid that is used to cool down the inverter system in various electronic devices. It plays a crucial role in maintaining the temperature of the inverter, preventing it from overheating and causing damage to the device. There are different types of inverter coolant available in the market, each with its own unique characteristics and properties.

One common type of coolant is ethylene glycol, which is a non-conductive liquid that has a high boiling point and excellent heat transfer capabilities. Another type is propylene glycol, which is similar to ethylene glycol but has a lower toxicity level. Some coolants are specifically designed for use in high-performance inverters, offering superior cooling performance and efficiency.

It is important to choose the right type of inverter coolant for your specific device to ensure optimal cooling and prevent any potential issues.

Water-based Coolants

water-based coolants, types of inverter coolant

Glycol-based Coolants

Glycol-based coolants are widely used in inverters to regulate temperature and prevent overheating. These coolants are specially designed to efficiently transfer heat away from sensitive electronic components, ensuring proper functioning and longevity of the inverter. There are different types of glycol-based coolants available, each with its own unique properties and advantages.

One common type is ethylene glycol, which is widely used in automotive applications due to its excellent heat transfer performance and low cost. Another type is propylene glycol, which is preferred in applications where there is a risk of accidental ingestion, as it is less toxic than ethylene glycol. Both types of glycol-based coolants offer excellent thermal stability, corrosion protection, and lubrication properties, making them the ideal choice for inverter cooling applications.

Additionally, these coolants are easily available and can be mixed with water in controlled ratios to achieve the desired thermal performance. So, whether you have a car, a solar inverter, or any other electronic equipment, glycol-based coolants can help in keeping them cool and running efficiently.

Synthetic Coolants

“Inverter coolants play a crucial role in maintaining the optimal temperature of the inverter system, ensuring its efficient functioning. One type of coolant commonly used is synthetic coolants. These coolants are specially designed to have excellent thermal conductivity, which helps in effectively dissipating heat generated by the inverter.

Synthetic coolants have a high heat transfer rate, making them ideal for use in high-performance applications. They are also non-conductive, which means they do not conduct electricity and are safe to use in electrical systems. Additionally, synthetic coolants have excellent stability and long-lasting performance, even in challenging operating conditions.

They are resistant to degradation and do not easily break down, ensuring the inverter system’s reliability. Synthetic coolants are available in different formulations, each with specific properties to suit various industrial applications. With their superior performance and durability, synthetic coolants are a popular choice among industries relying on inverter systems for smooth operations.

“

How Inverter Coolant Works

Inverter coolant is a crucial component in the functioning of inverters, which are responsible for converting direct current (DC) into alternating current (AC). But what exactly is inverter coolant? Well, think of it as the liquid that helps regulate the temperature of the inverter, much like how coolant keeps a car engine from overheating. When an inverter is in use, it generates heat as a byproduct, and if left unchecked, this heat can damage the delicate electronics within the inverter.

That’s where inverter coolant comes in. It circulates through the inverter, absorbing the excess heat and carrying it away, thus preventing overheating and ensuring that the inverter operates efficiently. Much like a cooling system in a car, inverter coolant is carefully designed to have a high boiling point and excellent heat transfer properties.

So, the next time you think about how an inverter works, remember the vital role played by inverter coolant in keeping things cool and running smoothly.

Heat Absorption

inverter coolant, heat absorption Inverter coolant plays a crucial role in keeping our electronic devices cool and preventing them from overheating. But have you ever wondered how inverter coolant actually works? Let’s break it down. Inverter coolant, also known as a heat transfer fluid, is a liquid or gas that absorbs and carries away excess heat from the inverter.

Think of it like a superhero cape that swoops in to save the day when things get too hot. When the inverter produces heat, the coolant flows through the system, absorbing the heat and carrying it to a heat exchanger. The heat exchanger acts as a kind of middleman, transferring the heat from the coolant to another medium, such as air or water.

This process cools down the coolant, allowing it to return to the inverter and absorb more heat. It’s like a never-ending cycle of cooling power. But how does the coolant actually absorb the heat? Well, it all comes down to its unique properties.

Inverter coolants are specifically designed to have a high heat capacity, meaning they can absorb a lot of heat before reaching their boiling point or becoming too hot to handle. Additionally, inverter coolants often have a low viscosity, which means they flow easily through the system and can efficiently absorb and transfer heat. They also have good thermal conductivity, allowing them to rapidly distribute the heat they absorb throughout the system.

So, the next time you marvel at your inverter’s ability to stay cool under pressure, remember that it’s all thanks to the incredible powers of inverter coolant. Without it, our beloved electronic devices would be at risk of overheating and malfunctioning. And that’s definitely not something we want!

Heat Transfer

inverter coolant, heat transfer

Heat Dissipation

inverter coolant, heat dissipation, overheating, vehicle performance, temperature regulation, engine efficiency, cooling system, thermal management, electric vehicle, traditional internal combustion engine, cooling fluids, heat transfer. Inverter coolant is an essential component in the thermal management system of electric vehicles, specifically in regulating the temperature of the inverter. The inverter plays a crucial role in converting the direct current (DC) from the battery into alternating current (AC) that powers the vehicle’s electric motor.

However, this conversion process generates a significant amount of heat, which, if not properly dissipated, can lead to overheating and impact the performance of the vehicle. Think of coolant as the cooling fluid that helps to dissipate the excess heat and maintain the optimal operating temperature. It circulates within the cooling system, absorbing heat from the inverter and transferring it to the radiator, where it is then cooled by airflow.

This continuous cycle helps to keep the inverter cool and prevent any overheating issues that can affect both the inverter’s performance and the overall efficiency of the electric vehicle. In comparison to traditional internal combustion engines, electric vehicles rely heavily on proper thermal management to ensure optimal performance. Inverter coolant, along with other cooling fluids, serves as a critical component in this thermoregulation process.

Without it, the inverter would be susceptible to heat damage, leading to decreased efficiency and potentially costly repairs. The importance of effective heat dissipation cannot be understated when it comes to electric vehicles. Inverter coolant not only helps to prevent overheating but also helps to optimize energy efficiency and prolong the lifespan of the inverter.

By regulating the temperature, it ensures that the inverter operates within its optimal temperature range, allowing for smooth power delivery and overall better vehicle performance. So, the next time you think about the impressive power and acceleration of an electric vehicle, remember that behind the scenes, there is a vital cooling system at work, with inverter coolant playing a critical role in maintaining the temperature balance for optimal engine efficiency and performance.

Maintenance and Replacement

Inverter coolant is a vital component of inverters used in various electrical systems. It is a special type of fluid that helps to regulate the temperature of the inverter and keep it running smoothly. Just like a car engine needs coolant to prevent overheating, an inverter requires coolant to dissipate the heat generated during operation.

The coolant circulates through the inverter and absorbs heat, which is then transferred to a heat exchanger where it is cooled down. This process helps in maintaining optimal operating temperatures and ensures the longevity and efficiency of the inverter. Inverter coolant is typically a mixture of water and antifreeze, similar to what is used in the cooling system of a car.

It is important to regularly check the coolant levels and replace it if necessary to avoid any potential damage to the inverter. So, next time you think about the inverter in your electrical system, remember that it works hard to keep things cool, with the help of its trusty sidekick – the inverter coolant.

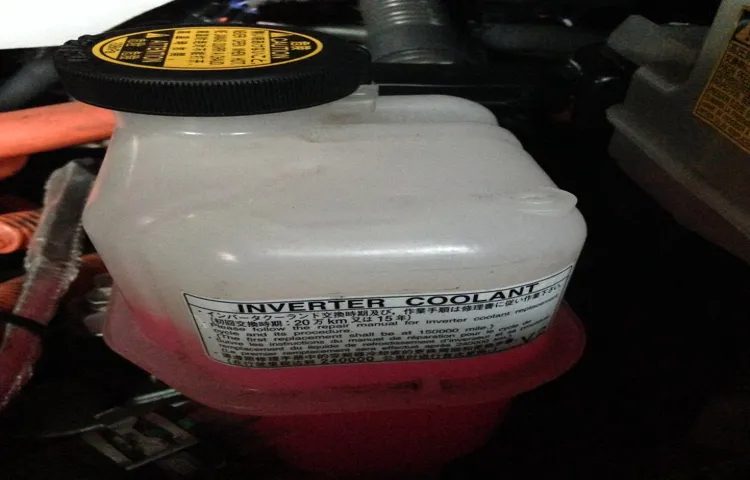

Checking Coolant Levels

“coolant levels” Checking your coolant levels is a crucial part of car maintenance that should never be overlooked. The coolant is responsible for keeping your engine cool and preventing it from overheating. Regularly checking your coolant levels can help you catch any potential issues before they become major problems.

To check your coolant levels, start by locating the coolant reservoir. It is usually a translucent plastic container that is marked with minimum and maximum lines. Make sure your engine is cool before you open the reservoir cap, as hot coolant can cause burns.

Once you have opened the cap, check the coolant level against the minimum and maximum lines. If the level is below the minimum line, you will need to add more coolant. It is important to use the correct type of coolant for your vehicle, as using the wrong one can cause damage.

If you are unsure of the type of coolant to use or how to add it, consult your vehicle’s owner manual or seek the help of a professional. Regularly checking your coolant levels is a simple yet important task that can help keep your engine running smoothly and prolong its lifespan.

Flushing the System

Flushing the system is an essential part of maintenance and replacement for any household or commercial plumbing system. Over time, minerals and other debris can accumulate in the pipes, leading to blockages and reduced water flow. Flushing the system involves removing these build-ups by forcing a large volume of water through the pipes at high pressure.

This process not only clears out any clogs but also helps to maintain the overall health and efficiency of the plumbing system. Think of it as giving your pipes a good deep clean, like when you descale a kettle or scrub a dirty pot. By regularly flushing your system, you can prevent issues such as leaks, clogs, and even burst pipes.

It’s like giving your plumbing a fresh start, ensuring everything runs smoothly and efficiently. So, don’t neglect the importance of system flushing as part of your regular maintenance routine. Your pipes will thank you for it!

Choosing the Right Coolant

Maintenance and Replacement of Coolant

Conclusion

In conclusion, inverter coolant is like the ultimate wingman that keeps our high-tech electronic devices cool under pressure. It’s the liquid superhero that swoops in to save the day, preventing our gadgets from overheating and performing their best when we need them the most. Think of inverter coolant as the cool-headed counselor that helps regulate temperature and dissipate heat, ensuring our devices stay calm, collected, and ready for action.

It’s like having a personal air-conditioning system for our electronics, keeping them chill when the heat is on. So, next time you hear someone mention inverter coolant, just remember that it’s the secret cool factor that keeps our tech in check. It’s the liquid guardian that never fails to keep our devices running smoothly and effortlessly, all while maintaining its own mysterious aura.

Inverter coolant, the covert hero of the tech world.”

FAQs

What is inverter coolant used for?

Inverter coolant is used to cool down the inverters in electronic devices, such as cars or solar panels, to prevent overheating and ensure optimal performance.

How often should inverter coolant be replaced?

The frequency of inverter coolant replacement depends on the manufacturer’s recommendations. However, it is generally recommended to replace the coolant every 2-3 years or as indicated in the user manual.

Is it possible to use a different type of coolant in an inverter?

It is not recommended to use a different type of coolant in an inverter, as it may not offer the same level of compatibility and performance. It is best to use the recommended coolant specified by the manufacturer.

What are the signs of low coolant in an inverter?

Some common signs of low coolant in an inverter include overheating, decreased performance, unusual noises, and warning lights or error messages on the device.

Can I mix different brands of inverter coolant?

It is generally not recommended to mix different brands of inverter coolant, as they may have different formulations or additives that can react negatively and affect the performance of the coolant.

How do I check the coolant level in an inverter?

To check the coolant level in an inverter, refer to the device’s user manual for specific instructions. In some cases, there may be a coolant reservoir or a dipstick to check the level. If unsure, it is best to consult a professional or contact the manufacturer for guidance.

Can inverter coolant be recycled or disposed of?

Inverter coolant should be handled and disposed of according to the manufacturer’s instructions. Some coolants may be recyclable, while others may require special disposal methods to prevent environmental harm. It is important to follow proper disposal procedures to ensure safety and environmental responsibility.