Have you ever wondered how to check the tread depth on your semi truck tires? It’s an essential part of truck tire maintenance and safety. Understanding the importance of tread depth and how to check it can prevent accidents and save you money in the long run. Tread depth refers to the vertical measurement between the top of the tread rubber to the bottom of the tire’s deepest grooves.

It’s the thickness of the rubber that comes into contact with the road. The lower the tread depth, the more likely it is for your truck to lose traction and hydroplane on wet roads. This can lead to accidents, especially when driving at higher speeds.

To check your tread depth, you can use a tire gauge or rely on the built-in wear indicators, which most modern semi truck tires have. The recommended minimum tread depth is 4/32 of an inch, but it’s always best to replace tires before they reach this point to ensure maximum safety and performance. Think of your semi truck tires as the foundation of your rig’s stability and control.

Without proper tire maintenance, you risk losing control on the road. It’s like the difference between driving on a smooth, well-paved freeway versus a wet, slippery dirt road. You have more control and stability with better tread depth.

In conclusion, understanding tread depth on your semi truck tires is crucial for safe and efficient driving. Regular tire maintenance and replacement will ensure that your truck stays on the road and avoids costly accidents.

Table of Contents

What is Tread Depth?

When it comes to new semi-truck tires, one important factor to consider is tread depth. Tread depth refers to the measurement of the space between the top of the rubber and the deepest grooves in the tire. This measurement is crucial to ensuring that your tires can safely grip the road and provide the necessary traction to keep your vehicle moving forward.

New tires generally have a tread depth of anywhere between 10/32 of an inch to 14/32 of an inch, but this can vary depending on the type and brand of tire you purchase. It’s important to regularly check your tire’s tread depth and replace them when they become worn down to ensure maximum safety and performance on the road. So, if you want to make sure that your semi-truck tires are in top-notch condition, make sure to keep an eye on their tread depth!

Definition of Tread Depth

Tread depth is a critical measurement when it comes to vehicle safety. Essentially, it refers to the distance between the surface of the tire tread and the bottom of its deepest grooves. Simply put, it’s the measurement of how much rubber is on the tire, and it’s a good indicator of whether a tire needs to be replaced.

As a tire wears down, its tread depth decreases, and it becomes more prone to skidding and hydroplaning, which can be extremely dangerous in wet conditions. The legal limit for minimum tread depth is typically around 2/32 of an inch, but it’s generally recommended that tires be replaced when the tread depth falls below 4/32 of an inch to ensure maximum safety on the road. Checking your tire tread depth regularly is an important part of vehicle maintenance, and it’s a quick and easy process that can help you avoid accidents and keep your car running smoothly.

Importance of Tread Depth

Tread depth is the measurement of the distance between the top of a tire’s tread to the bottom of its grooves. It plays a crucial role in ensuring proper traction on the road, especially in wet or slippery conditions. A tire’s tread depth affects its ability to grip the road, making it a key factor in determining a tire’s performance and safety.

In fact, regulators have established guidelines for minimum tread depths to ensure that vehicles are safe to drive. When the tread depth wears down below these minimum levels, it’s time to consider replacing the tire. Proper maintenance of tire tread depth is essential for optimal tire performance, fuel economy, and road safety.

Always check your tires regularly, and if you’re unsure about their condition, consult a professional. It’s better to spend a little extra on new tires than to risk an accident or other serious consequences.

Measuring Tread Depth on a New Semi Tire

When it comes to measuring the tread depth on a new semi tire, it’s important to know the baseline depth so that you can monitor wear over time. Generally speaking, the new tread depth on a semi tire can be around 17/32 of an inch. But measurements may vary based on the specific tire model and manufacturer.

To get an accurate reading, you’ll need to use a tread depth gauge tool, which can be purchased at most auto stores. Simply insert the gauge pins into the grooves of the tread, and the tool will display the depth measurement. Keeping track of your tire’s tread depth can help prevent blowouts and other safety hazards on the road.

As a rule of thumb, once your tire tread depth falls below 4/32 of an inch, it’s time to start considering replacements. So, if you’re ever unsure about the tread depth on your semi tires, be sure to check it for optimal safety and performance on the road.

How to Measure Tread Depth

When it comes to measuring tread depth on a new semi tire, there are a few things you need to keep in mind. First, it’s important to use an accurate tool to measure the depth. One popular option is a tread depth gauge, which can be found at most auto supply stores.

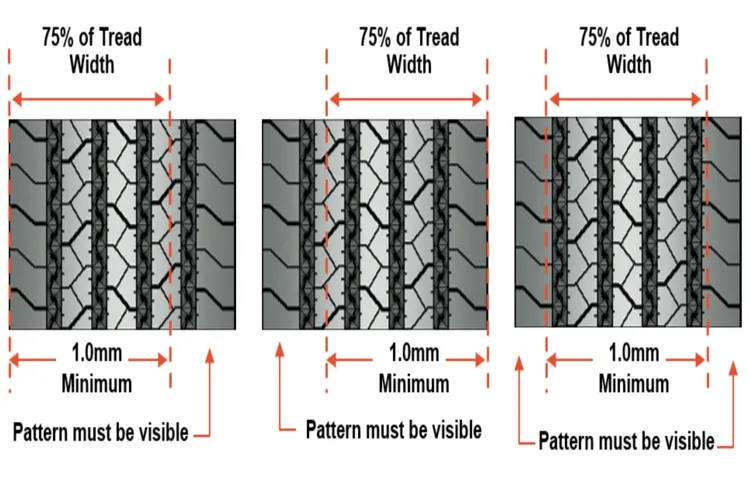

To use it, simply press the gauge firmly into the groove of the tire and take note of the measurement. The depth should be measured across the entire width of the tire, in at least three different spots. This will give you an accurate idea of the overall depth and condition of the tire.

Keep in mind that new semi tires typically come with a deeper tread depth than used ones, so you’ll want to compare your measurements to the manufacturer’s recommended depth for the specific tire model. Taking these steps to measure your tread depth can help ensure that your tires are in good condition and provide optimal performance on the road.

Factors Affecting Tread Depth

When measuring the tread depth on a new semi tire, there are certain factors that need to be taken into consideration. One of the main factors is the type of tire you are using. Different types of tires have different tread depths, so it’s important to know what kind of tire you have before measuring its depth.

Another factor is the condition of the tire itself. If the tire is worn or damaged, this can affect the accuracy of the tread depth measurement. Additionally, the type of surface the tire is being measured on can also impact the measurement.

Ideally, you will want to measure the tread depth on a clean, dry, and flat surface to ensure the most accurate measurement possible. In general, most new semi tires have a tread depth of around 14 to 16 millimeters. Measuring the tread depth on a new tire is important because it can give you an idea of how long the tire will last and when it will need to be replaced.

By regularly measuring the tread depth, you can ensure that your tires are always in good condition and operating safely on the road.

Average Tread Depth on a New Semi Tire

When it comes to purchasing new semi tires, it’s important to consider the average tread depth to ensure a safe and smooth ride. The average tread depth on a new semi tire is typically around 14/32 of an inch. However, it’s important to measure the tread depth periodically to ensure safety and prolong the life of the tire.

You can do this by using a tread depth gauge, which can be found at most auto parts stores. It’s essential to keep an eye on the tread depth as it directly correlates with safe stopping distances and overall tire wear. Without sufficient tread depth, your semi could potentially skid or hydroplane on wet or slippery roads, putting you and others at risk.

Additionally, regularly monitoring your tire’s tread depth can help prevent unexpected blowouts, saving you time and money in the long run. Overall, paying attention to tread depth is a crucial aspect of maintaining the safety and longevity of your semi tires.

Maintenance and Replacement of Semi Truck Tires

When it comes to maintaining and replacing semi truck tires, knowing the tread depth on a new tire is important information. The tread depth on a new semi tire can vary depending on the make and model, as well as the specific purpose of the tire. However, most new semi tires have a tread depth of around 14/32 of an inch.

It’s important to keep in mind that as the tire is used and wears down, the tread depth will decrease, eventually reaching a point where the tire needs to be replaced for safety reasons. Federal regulations dictate a minimum tread depth of 2/32 of an inch for steer tires and 4/32 of an inch for drive and trailer tires. It’s crucial for the safety of drivers and other motorists on the road that semi truck tires are properly maintained and replaced when necessary.

Regular inspections and routine maintenance can help catch any issues with tire wear before they become dangerous.

When to Replace Tires Based on Tread Depth

When it comes to taking care of your semi truck, it’s important to keep a close eye on your tires. After all, they’re what keep you rolling down the road safely and smoothly. One of the most crucial aspects of maintaining your tires is knowing when it’s time to replace them.

And the best way to do that is by monitoring the tread depth. As a general rule of thumb, once your tire tread reaches 4/32 of an inch or less, it’s time to start thinking about replacement. This is especially important for commercial trucks, as worn-out tires can increase the risk of blowouts and accidents.

To ensure the longevity and safety of your semi truck, be sure to schedule regular tire inspections and replacements as needed. It’s a small investment that can save you a lot of headache and money in the long run.

Tips for Maintaining Tread Depth

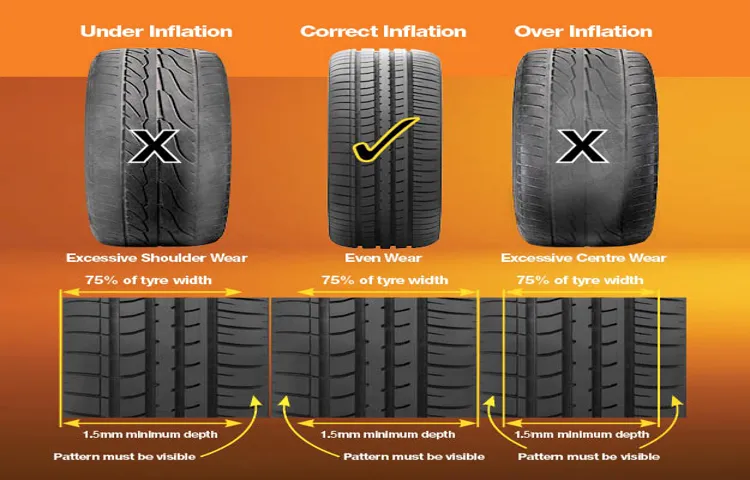

Maintaining tread depth is crucial for safe and efficient driving of semi-trucks. Regularly checking the tread depth of the tires, especially before embarking on long journeys, is important to avoid unexpected blowouts or flat tires. Making sure the tires are inflated to the correct pressure and that the wheels are correctly aligned can also help prolonging the life of the tires.

When the treads become worn out, replacing the tires is recommended – bald or low tread tires can lead to reduced grip on the road, making the vehicle harder to control, particularly in wet and slippery conditions. Regular maintenance and replacement of semi-truck tires can save truckers time, money and potentially save lives.

Conclusion

In conclusion, the tread depth on a new semi tire is like the icing on a cake – it’s the part that makes all the difference. With a precise tread depth, a new semi tire can grip the road and provide top-notch performance for thousands of miles. So, next time you hit the highway, remember to check your tread depth and ensure that you’re rolling both safely and smoothly along the way.

“

FAQs

What is considered a new semi tire?

A new semi tire is one that has never been used on the road before and has full tread depth.

What is the typical tread depth on a new semi tire?

The typical tread depth on a new semi tire can vary, but it is usually between 13/32 and 14/32 inch.

How often should I check the tread depth on my semi tires?

It is recommended to check the tread depth on your semi tires at least once a month and before and after long trips.

What is the legal minimum tread depth for semi tires?

The legal minimum tread depth for semi tires is 4/32 inch, but it is recommended to replace tires at 6/32 inch for safety reasons.

How does low tread depth affect my semi’s performance?

Low tread depth can cause reduced traction, longer stopping distances, and increased risk of hydroplaning, among other negative effects.

Can I retread my semi tires to extend their lifespan?

Yes, many semi tires are designed to be retreaded multiple times to save money and reduce waste.

How can I measure the tread depth on my semi tires accurately?

You can use a tire tread depth gauge or a penny, placing it upside-down in the tread grooves with Lincoln’s head facing down. If the top of his head is visible, the tread is too low.