So, you’ve finally gotten your hands on a powerful 1000 watt power inverter. Congratulations! This handy device allows you to convert DC power from your vehicle’s battery into AC power, making it ideal for camping trips, road trips, and emergency power backup. But now comes the important question: how do you choose the right cable terminals for your 1000 watt power inverter? Choosing the right cable terminals is crucial for ensuring efficient power transfer and preventing any potential electrical hazards.

The cable terminals act as the bridge between your power inverter and the battery, allowing the power to flow smoothly. But with so many options available in the market, it can be overwhelming to make the right choice. Imagine it like this – think of the cable terminals as the connectors on a puzzle piece.

If the connectors don’t fit properly, the puzzle won’t come together. Similarly, if the cable terminals are not compatible with your power inverter and battery, you may encounter issues such as overheating, power loss, or even damage to your equipment. So, how do you ensure that you choose the right cable terminals? Well, it boils down to a few key factors – the wire gauge, the type of terminal, and the compatibility with your power inverter and battery.

Each of these factors plays a crucial role in ensuring optimal performance and safety. In this blog post, we will provide you with essential tips and guidelines to help you make an informed decision when it comes to selecting the right cable terminals for your 1000 watt power inverter. We will explain the importance of wire gauge, discuss different types of cable terminals, and outline the compatibility factors that you should consider.

By the end of this blog post, you will have a clear understanding of what to look for when choosing cable terminals and feel confident in making the right choice for your power inverter setup. So, let’s get started!

Table of Contents

Understanding Power Inverters

When it comes to using a 1000 watt power inverter, it’s important to consider the size of the cable terminals you’ll need. The cable terminals are what connect the power inverter to your battery, so it’s essential that they are the right size to handle the power being transferred. The size of the cable terminals will depend on a few factors, such as the length of the cable and the current rating of the power inverter.

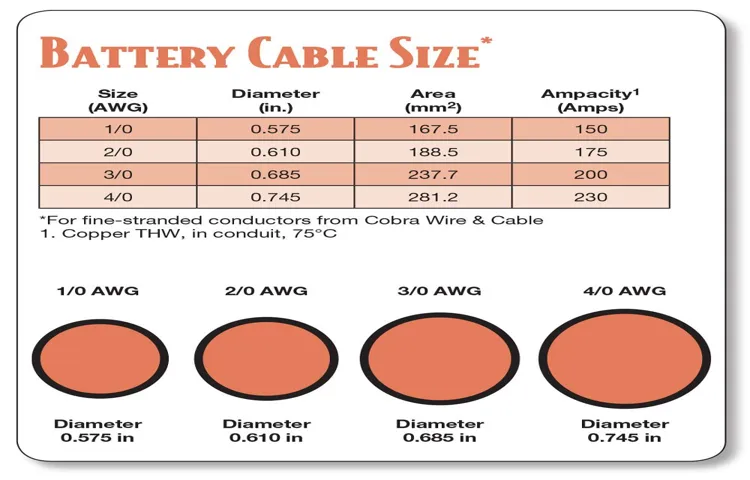

Generally, for a 1000 watt power inverter, you would need cable terminals that can handle around 105-125 amps. In terms of cable thickness, you would typically need 2 AWG (American Wire Gauge) cables. It’s always a good idea to consult the manufacturer’s recommendations or consult a professional if you’re not sure about the right size cable terminals for your specific power inverter.

What is a power inverter?

power inverter, inverter, electricity, AC power, DC power, convert, appliances. A power inverter is an essential device in our modern lives that allows us to use our electronic devices, even when we are away from a traditional power source. Imagine you are on a road trip and want to charge your laptop or use your blender to make a smoothie.

Without a power inverter, you would be out of luck. But what exactly is a power inverter? Well, it is a device that converts DC (direct current) power into AC (alternating current) power. In simpler terms, it takes the electricity from your car’s battery, which is DC power, and converts it into the AC power needed to run your appliances.

This means that you can plug in your laptop, blender, or any other AC-powered device and use it just as you would at home. The power inverter acts as a bridge, filling the gap between the DC power source and your AC-powered appliances. It is a versatile tool that allows us to stay connected and make our lives more convenient, whether we are on the road or in the great outdoors.

So next time you’re planning a road trip or heading out to the campsite, don’t forget to bring along your trusty power inverter to keep your devices charged and your adventures powered up.

How does a power inverter work?

power inverter, understanding power inverters, how does a power inverter work You may have come across the term “power inverter” but wondered how it actually works. Well, let me break it down for you in simpler terms. A power inverter is a device that converts DC (direct current) power from a battery into AC (alternating current) power that can be used to run household appliances and electronic devices.

It’s like a translator between two languages – it takes the energy from the battery, which is in the form of DC power, and translates it into AC power that our devices can understand and use. So, in essence, a power inverter allows you to use your electronic gadgets and appliances when you don’t have access to mains electricity. Whether you’re camping, traveling, or experiencing a power outage, a power inverter can come to the rescue by providing you with the necessary AC power.

So, the next time you plug in your laptop or charge your phone using a power inverter, remember that it’s working its magic behind the scenes, converting DC power into AC power for your convenience.

Why do you need a power inverter?

power inverter, understanding power inverters

Determining the Cable Size for your Power Inverter

When it comes to determining the cable size for your power inverter, it’s important to consider the wattage of the inverter and the distance between the inverter and the battery. For a 1000 watt power inverter, you’ll want to use a cable that can handle the high current that the inverter requires. As a general rule of thumb, you’ll want to use a cable with a gauge size that is appropriate for the length of the cable run.

For shorter cable runs, you can use a thicker gauge cable, while longer cable runs will require a thinner gauge cable. This is because thicker gauge cables have a higher ampacity and can handle more current. Additionally, it’s also important to use cable terminals that are appropriate for the cable size and the inverter’s power output.

Using the correct cable and terminals will ensure that your power inverter operates safely and efficiently.

What factors determine the cable size?

Determining the cable size for your power inverter is an essential aspect of ensuring efficient and safe operation of your power system. Several factors come into play when determining the appropriate cable size for your power inverter. One crucial factor is the current rating of your power inverter.

The higher the current rating, the larger the cable size you will require. Another important consideration is the distance between your power inverter and the battery. The longer the distance, the larger the cable size you will need to compensate for any voltage drop that may occur.

Additionally, the type of cable material and its resistance play a significant role in determining the cable size. Copper cables are commonly used due to their low resistance, while aluminum cables have a higher resistance and may require larger sizes. By taking these factors into account, you can determine the cable size that is appropriate for your power inverter, ensuring optimal performance and safety.

Calculating the cable size for a 1000 watt power inverter

power inverter, cable size, watt, determine Determining the right cable size for your power inverter is crucial to ensure optimal performance and prevent any damage or overheating. When it comes to a 1000-watt power inverter, you need to consider the wattage, current, and voltage to determine the appropriate cable size. The cable size is important as it affects the amount of current that can flow through the cables without significant voltage drop.

To calculate the cable size, you will first need to determine the current by dividing the wattage (1000 watts in this case) by the voltage (typically 12 volts for a power inverter). So, in this case, the current would be approximately 833 amps (1000 watts divided by 12 volts).

Once you have the current, you can refer to a wire sizing chart or consult a professional electrician to determine the appropriate cable size. Keep in mind that it’s always better to go for a slightly larger cable size to ensure a safe and efficient operation of your power inverter.

Types of Cable Terminals

When it comes to choosing the right cable terminals for a 1000-watt power inverter, several factors need to be considered. The size of the cable terminals will depend on the gauge or thickness of the cables being used. In general, a 1000-watt power inverter will require cables with a more significant gauge to handle the higher amount of power.

Typically, a gauge of 4 or 2 AWG (American Wire Gauge) would be suitable for a 1000-watt inverter. It’s essential to ensure that the cable terminals match the gauge of the cables to ensure a secure and efficient connection. Additionally, it’s also crucial to consider the type of cable terminals needed, such as ring terminals or lugs, depending on the specific requirements of the power inverter and the electrical system it will be connected to.

Ring terminals

Ring terminals are a type of cable terminal that is commonly used in electrical and electronic applications. They are called “ring” terminals because of their ring-shaped design. These terminals are used to connect wires to various components, such as switches, motors, and circuit breakers.

One of the main advantages of ring terminals is that they provide a secure and reliable connection. The ring shape allows for easy insertion of the wire, and the terminal can be crimped or soldered to keep the wire in place. The ring terminal also has a hole in the center, which allows it to be bolted or screwed onto the component.

This provides a strong mechanical connection. Ring terminals are available in various sizes and materials, including copper, brass, and stainless steel. They can also be insulated or non-insulated, depending on the application.

Insulated ring terminals have a plastic or rubber coating, which provides protection against electrical shock and prevents the terminal from coming into contact with other conductive surfaces. Non-insulated ring terminals are often used in automotive applications, where space is limited. Overall, ring terminals are a versatile and reliable solution for connecting wires in electrical and electronic systems.

Spade terminals

Spade terminals, also known as spade connectors or fork terminals, are a popular type of cable terminal used in electrical and electronic applications. They are called spade terminals because of their resemblance to a gardening tool – the shovel or spade. These terminals consist of a flat metal blade or “tongue” with a hole at one end.

The hole allows the terminal to be easily attached to a stud or screw on a device, such as a circuit breaker or terminal block. Spade terminals are designed to provide a secure and reliable electrical connection, and they can be easily connected and disconnected without the need for soldering or crimping. They are available in various sizes to accommodate different wire gauges and stud sizes.

The flat blade design also allows for easy identification of positive and negative terminals, making wiring tasks quicker and more efficient. Overall, spade terminals are a versatile and practical option for connecting wires in a wide range of applications.

Lug terminals

“Lug terminals” Lug terminals are a type of cable terminal that provide a secure and efficient connection for electrical cables. They are widely used in various applications, including automotive, industrial, and telecommunications. Lug terminals are designed with a hole or opening, where the cable can be inserted and then secured using a screw or bolt.

This type of connection ensures a strong and reliable bond, preventing the cable from coming loose or disconnecting due to vibrations or other external factors. Lug terminals come in various sizes and materials, such as copper or aluminum, to accommodate different cable sizes and electrical requirements. They are an essential component in electrical wiring systems, allowing for easy installation and maintenance.

Whether you are working on a DIY project or a professional electrician, lug terminals are a must-have for your cable termination needs.

Choosing the Right Cable Terminal Size

When choosing the right cable terminal size for a 1000 watt power inverter, it’s important to consider the specifications and requirements of the power inverter itself. Cable terminals are used to connect the power inverter to a power source, such as a battery, and the size of the terminals can greatly impact the performance and safety of the system. In order to determine the appropriate cable terminal size, you should first consult the manufacturer’s specifications for the power inverter.

These specifications will typically include information on the recommended cable size, which will depend on factors such as the maximum current capacity of the inverter and the distance between the inverter and the power source. Choosing the wrong cable terminal size can result in efficiency loss, voltage drop, and even potential damage to the power inverter and other components of the system. It’s always better to err on the side of caution and choose a terminal size that is slightly larger than the minimum requirement specified by the manufacturer.

In addition to the size of the cable terminals, it’s also important to ensure that the terminals are properly installed and securely connected to the power inverter and power source. Loose or improperly installed terminals can cause resistance and heating, which can lead to a reduction in the overall performance and efficiency of the system. In conclusion, when choosing the right cable terminal size for a 1000 watt power inverter, it’s important to consider the manufacturer’s specifications, as well as the overall safety and performance of the system.

By following these guidelines, you can ensure that your power inverter operates efficiently and safely.

Matching the cable terminal size to the inverter’s input terminals

Choosing the right cable terminal size is a crucial consideration when connecting your inverter to power sources for maximum efficiency and safety. It’s like making sure you have the right size shoes for your feet – if the size is too small, it will be uncomfortable and restrict your movement, but if it’s too big, you risk tripping or losing your shoes altogether. Similarly, using cable terminals that are too small for the inverter’s input terminals can result in poor electrical connections, overheating, or even damage to your equipment.

On the other hand, using terminals that are too large can be cumbersome and increase the risk of accidental contact, potentially leading to electrical hazards. Therefore, it’s important to carefully match the cable terminal size to the inverter’s input terminals to ensure a secure and efficient connection, minimizing the risk of electrical issues and maximizing the performance of your system.

Considering the cable gauge and terminal size

choosing the right cable terminal size

Determining the required cable terminal size for a 1000 watt power inverter

When choosing the right cable terminal size for a 1000 watt power inverter, there are a few factors to consider. The cable terminal size refers to the diameter of the hole in the terminal where the cable is connected. It is important to choose the correct size to ensure a secure connection and to prevent any overheating or voltage drop issues.

The size you choose will depend on the gauge of the cable you are using and the maximum current the inverter is capable of producing. It is recommended to consult the manufacturer’s specifications for the inverter to determine the appropriate cable terminal size. This will ensure that you choose a terminal that is suitable for the power output of the inverter and will provide a safe and reliable connection.

So, before hooking up your 1000 watt power inverter, take the time to research and select the right cable terminal size for your specific application.

Conclusion

In conclusion, when it comes to selecting the right cable terminals for a 1000 watt power inverter, one must consider the saying ‘size does matter’. Just like Goldilocks trying to find the perfect fit, it is crucial to find the terminals that are not too big or too small, but just right. You see, using the wrong cable size could result in a catastrophic fizzle or a power meltdown, leaving you feeling more shocked than an electric eel at a disco party.

So, make sure to do your research, consult the power inverter handbook, and measure twice before making a single connection. Remember, the right size cable terminals will not only keep your power flowing smoothly but also save you from any hilarious yet electrifying accidents. Stay powered up and be the conductor of electric success!”

FAQs

What are cable terminals?

Cable terminals are connectors that are used to connect cables to devices or electrical systems. They provide a secure and reliable connection for transmitting electrical signals or power.

What factors should be considered when choosing cable terminals for a 1000 watt power inverter?

When selecting cable terminals for a 1000 watt power inverter, it is important to consider factors such as the current rating, wire size, insulation type, and connection method. These factors will ensure that the cable terminals are able to handle the power requirements and provide a safe and efficient connection.

What is the recommended cable size for a 1000 watt power inverter?

The recommended cable size for a 1000 watt power inverter depends on the length of the cable run and the maximum current that the inverter is expected to draw. As a general guideline, a 4 AWG (American Wire Gauge) cable is often suitable for shorter runs, while a 2 AWG cable may be required for longer runs or higher currents.

Can I use regular electrical cables for connecting a 1000 watt power inverter?

Regular electrical cables may not be suitable for connecting a 1000 watt power inverter due to their current handling capabilities. It is recommended to use cables specifically designed for high-current applications, such as welding cables or battery cables, to ensure safe and efficient operation.

What type of cable terminals are commonly used for high-power inverters?

For high-power inverters like a 1000 watt inverter, commonly used cable terminals include ring terminals, battery terminal connectors, or lug terminals. These terminals provide a secure and reliable connection, and they can accommodate the higher current requirements of the inverter.

How do I determine the current rating of cable terminals for a 1000 watt power inverter?

The current rating of cable terminals can typically be found in the product specifications or manufacturer’s documentation. It is important to select cable terminals that have a current rating equal to or higher than the maximum current that the inverter is expected to draw to ensure safe and reliable operation.

Are there any specific safety precautions I should follow when installing cable terminals for a 1000 watt power inverter?

Yes, when installing cable terminals for a 1000 watt power inverter, it is important to follow safety precautions such as ensuring proper insulation, securely fastening the terminals, and avoiding overloading the cables. It is also recommended to consult the manufacturer’s guidelines and local electrical codes for specific installation requirements and safety recommendations.